Decorative and Constructive Aluminum Honeycomb Sheets with Coated Embossed Aluminum Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

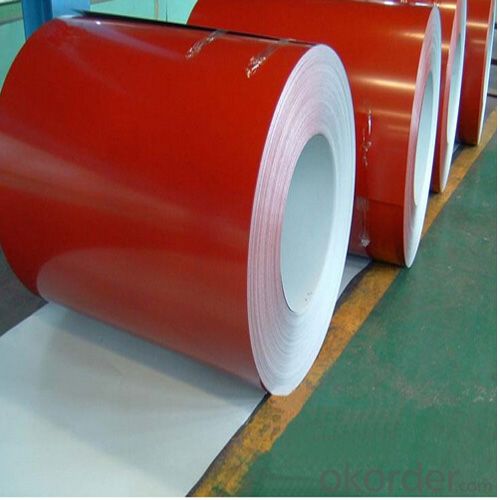

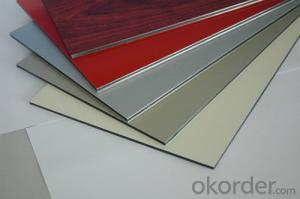

1.Structure of Coated Aluminium Embossed Coils for Decoration and Construction Description:

The main products of our company are aluminium sheet, coil, aluminium stucco embossed sheet, five-bars embossed sheet, diamond embossed sheet, color coated aluminium sheet, aluminium foil and aluminium circle. They are widely used in daily life. The aluminum sheets are used in many places, transportation, decoration, construction and so on.

The function is Fire-proofing, Water-proofing, Heat-resistance, Anti-static, Voice-resistance, Mositure-proofing, Corrosion Resistance. The Application is Decoration and Transporation, Wall, Window and Door, Antiskid Board.

2.Main Features of Coated Aluminium Embossed Coils for Decoration and Construction:

Coating Thickness: 0.01mm-0.15mm, 0.02mm0.025mm

Surface Treatment: Color Coated, Embossed

Coating Color: Red, Green, Blue, etc

Coating: PE/PVDF

Surface: One Side Bright, Two Sides Brigh

3. Coated Aluminium Embossed Coils for Decoration and Construction Images:

4. Coated Aluminium Embossed Coils for Decoration and Construction Specification:

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Ti | Al |

| 1060 | 0.2 | 0.25 | 0.05 | 0.03 | 0.03 | 0.05 | 0.015-0.02 | 99.6 |

| 1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | 0.05 | 0.015-0.02 | 99.5 |

| 1100 | 0.2 | 0.5-0.6 | 0.05 | 0.05 | - | 0.05 | 0.015-0.02 | 99.0 |

| 1235 | 0.65 | 0.05 | 0.05 | 0.05 | 0.1 | 0.06 | 99.35 | |

| 3003 | 0.2 | 0.3-0.45 | 0.05-0.15 | 1.05-1.35 | - | 0.10 | - | - |

| 3102 | 0.2 | 0.1-0.4 | <0.1< span=""> | 0.1-0.4 | - | <0.05< span=""> | <0.05< span=""> | - |

| 3105 | 0.6 | 0.7 | 0.3 | 0.3-0.8 | 0.2-0.8 | 0.4 | 0.1 | - |

| 5052 | 0.088 | 0.296 | 0.007 | 0.038 | 2.253 | 0.009 | 0.012 | - |

| 8011 | 0.55-0.59 | 0.69-0.75 | 0.02 | 0.025 | 0.01 | 0.01 | 0.015-0.02 | - |

| 5083 | 0.4 | 0.4-1.0 | 4.0-4.9 | 0.25 | R | |||

| 5754 | 0.07 | 0.3 | 0.006 | 0.18 | - | - | 0.016 | R |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.25 | 0.15 | R |

| 6082 | 0.8-1.5 | 0.5 | 0.1 | 0.4-1.0 | 0.6-1.2 | 0.2 | 0.1 | R |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: What's the maximum size of 3 mm thick aluminum sheet?

- See tolerance taggingIf there is no tolerance, see the accuracy level of the workpiece and check the tolerance listA 3-4 mm deviation is acceptable if the magnitude is not noted and is of no importanceThat is, the 3.5mm is OK, if the lower accuracy is generally 2.95

- Q: How much is the aluminum plate shearing machine?

- Guillotine shears. Consult medirect dealAskCan cut 2 millimeters, 1.2 meters wide on the lineChasing the answerJust get a mechanical guillotine, 3*1500Contact me if necessary

- Q: Are 101 aluminum sheets readily available in the market?

- Indeed, the market offers a wide range of readily available 101 aluminum sheets. Owing to their exceptional resistance to corrosion, impressive strength, and lightweight nature, these sheets find frequent use across various industries and applications. They can be conveniently obtained from metal supply stores, online marketplaces, and specialized aluminum suppliers. Moreover, customers have the liberty to select from a variety of sizes, thicknesses, and finishes for 101 aluminum sheets, ensuring the perfect match for their specific needs.

- Q: Can aluminum sheet be used for automotive body-in-white applications?

- Certainly, automotive body-in-white applications can utilize aluminum sheet. Aluminum possesses the advantageous qualities of being lightweight, robust, and long-lasting, rendering it an optimal substance for automotive purposes. It presents a remarkable strength-to-weight ratio, which contributes to enhancing fuel efficiency and overall vehicle performance. Furthermore, aluminum excels in resisting corrosion, enabling it to endure harsh environmental conditions. Its malleability permits the creation of intricate and sophisticated designs, empowering manufacturers to fabricate automotive structures that are simultaneously light and sturdy. In recent times, the utilization of aluminum in automotive body-in-white applications has gained considerable popularity, primarily due to its ability to decrease vehicle weight and emissions while simultaneously maximizing safety and performance.

- Q: i want to build a smelter to recycle aluminum auto parts

- Tita, while providing an elegant answer, forgot to mention that it is mostly cut and paste from Wikipedia. I'll provide the link for her below. She also forgot to copy and paste the part about aluminum oxidizing easily when it is heated and melted. If you are trying to smelter aluminum, you will need to have a compressed or dense mass of aluminum and a smelter that is airtight. Otherwise, it will just oxidize right back into aluminum oxide, which is a white powder. You've probably seen this when you throw a beer can in the campfire? good luck and have fun in your endeavors. And always remember to cite your source!

- Q: Are aluminum sheets resistant to corrosion?

- Indeed, corrosion is highly resisted by aluminum sheets. Upon exposure to air, aluminum creates a safeguarding oxide layer on its surface, effectively inhibiting any subsequent corrosion. This oxide layer serves as a shield, safeguarding the core metal against environmental elements, including moisture and corrosive substances. Furthermore, due to its minimal inclination to rust, aluminum is extensively favored in numerous domains where corrosion resistance is paramount, such as the fabrication of aircraft, automobiles, and marine vessels. In conclusion, aluminum sheets are renowned for their extraordinary ability to withstand corrosion, thereby enhancing their sturdiness and durability.

- Q: Are aluminum sheets magnetic?

- Aluminum sheets lack magnetic properties and do not exhibit any attraction or interaction with magnets. This is due to the absence of magnetic elements like iron or nickel in aluminum, making it a non-magnetic metal.

- Q: Can aluminum sheets be used for lithographic printing plates?

- Yes, aluminum sheets can be used for lithographic printing plates. Aluminum is commonly used in lithography due to its excellent characteristics such as light weight, corrosion resistance, and durability, which make it suitable for the printing process.

- Q: There are about 200 holes on the aluminum plate to be machined. There are 100 M12 thread holes, and the rest are 15MM through holes. The tolerance is +0.02. Seeking detailed processing technology, is the first hole or first processing plane, how to control the amount of deformation of the plate, if the milling process can not guarantee flatness, on the grinder, then the 2 surfaces to stay 2MM margin? Are there any 15MM through holes that can be used to maintain tolerances, or do they need to be boring?. Great God advice, the best detail. Aluminum so much done before, no experience, if it does it scrapped.

- The thickness of 2 to 1. fly in place stress to ensure the flatness of the fitter leveling 0.13 more than the Xicheng pay attention to the protection of the appearance of 4 to ensure the flatness of the fabricated fitter. - this thing must not need to be so high, 100 M12 threaded holes, you still press the map to ensure that ah? Such a large plate deformation, 2 millimeters below the hole can be pressed to do

- Q: What is the typical fatigue life of aluminum sheets?

- The fatigue life of aluminum sheets can vary depending on several factors such as the alloy used, sheet thickness, manufacturing process, and the specific application they are used for. Generally, aluminum sheets have a higher fatigue strength compared to other materials, allowing them to endure numerous cyclic loading cycles before failure. However, it is important to consider that fatigue life can be influenced by different factors including stress levels, loading conditions, and environmental elements like temperature and humidity. When aluminum sheets are exposed to high stress levels, cyclic loading, or harsh environmental conditions, their fatigue life may decrease. In certain applications where aluminum sheets are subjected to low stress levels or are not exposed to cyclic loading, they can have an unlimited fatigue life. Conversely, in high-stress applications or when subjected to cyclic loading, aluminum sheets typically have a limited fatigue life that can range from thousands to millions of cycles. To accurately determine the fatigue life of aluminum sheets for a specific application, it is recommended to refer to relevant industry standards, test data, or consult with material engineers or manufacturers who can provide more precise information based on the specific parameters and usage conditions.

Send your message to us

Decorative and Constructive Aluminum Honeycomb Sheets with Coated Embossed Aluminum Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords