1 4 Brushed Aluminum Sheets - High Quality Decoration and Roofing Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

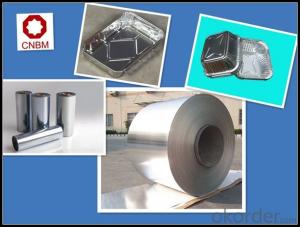

1.Structure of Decoration and Roofing Aluminum Coil Description:

Mill Finish Plain Aluminum are widely used for building use, decoration use, making cookware, busing making, shipping building, airplane making and so on。Sizes of aluminum sheet for decoration use: Thickness: 0.3mm~300mm Width: Under 2000mm ( Standard: 1000mm, 1219mm, 1500mm, 1540mm) Length: Under 10000mm. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of Decoration and Roofing Aluminum Coil:

Good mechanical properties.

Easy processing, wearability.

Corrosion resistance

Resistance to oxidation.

3. Decoration and Roofing Aluminum Coil Images:

4. Decoration and Roofing Aluminum Coil Specification:

| Aluminium sheet | |||||

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Are aluminum sheets suitable for architectural facades?

- Yes, aluminum sheets are highly suitable for architectural facades. They offer numerous benefits such as durability, lightweight construction, corrosion resistance, and versatility in design. Aluminum sheets can be easily shaped and formed into various sizes and shapes, allowing for creative and unique architectural designs. Additionally, their ability to withstand harsh weather conditions makes them a reliable choice for long-lasting facades.

- Q: What is the modulus of elasticity for aluminum sheets?

- Aluminum sheets possess a modulus of elasticity, commonly referred to as Young's modulus, which typically ranges at approximately 69 GPa (gigapascals) or 10 million pounds per square inch (psi). This numerical figure signifies the extent of stiffness and rigidity exhibited by the material. Nevertheless, it is crucial to acknowledge that the modulus of elasticity may experience slight variations contingent upon the precise alloy composition and tempering of the aluminum sheet.

- Q: Can the aluminum sheets be used for manufacturing heat sinks?

- Yes, aluminum sheets can be used for manufacturing heat sinks.

- Q: Are aluminum sheets suitable for soundproofing applications?

- Aluminum sheets are not typically suitable for soundproofing applications as they have low mass and do not effectively block or absorb sound waves.

- Q: I'm gonna drop the dime and get a bass boat. other than weight why is a fiberglass better than aluminum?I'm looking at the difference between the top of the line BassTracker and the bottom of the line Nitro. I only want about a 90 -115 hp and I'm gonna buy a couple years old to save some money.. so what are the pros - cons?

- Fiberglass boats ARE NOT more durable. A typical fiberglass bass boat will last approx 12-15 years with regular use- depending on brand and if you plan to fish tournaments. (Tournaments can ruin a boat in NO time.) Typically, GOOD aluminum hulls will last a LONG time- if properly cared for.

- Q: why does 10% sulfuric acid not react with aluminum sheet?

- 10% sulfuric acid has a high concentration and will be passivated and formulate a layer of oxide film after reacting with aluminum,and the reaction will stop after seperating sulfuric acid and aluminum. there is a layer of Al2O3 oxide film on the surface of aluminum, so it's hard for sulfuric acid to break the oxide film and react with aluminum.

- Q: Can aluminum sheets be used for automotive applications?

- Yes, aluminum sheets can be used for automotive applications. Aluminum is lightweight, strong, and has excellent corrosion resistance, making it an ideal material for various automotive components such as body panels, hoods, doors, and engine parts.

- Q: I would like to use an alloy of copper often called aluminum bronze or aluminum brass for making wire wrapped jewelry but I am unable to find a supplier. An alloy that has no zinc or lead would be best to avoid toxicity problems. This alloy should be principally copper and aluminum but other added materials would be acceptable if not toxic. Nickel, silicon, manganese, and iron are sometimes added to increase performance of the alloy and should be acceptable (no lead or zinc please). The material obviously needs to be bendable enough to work with wire wrapping so if it is brittle it will not work. It should then be at least as usable as aluminum, copper, or stainless steel wire.

- Aluminum okorder which is a site for serious jewelers to share solutions and they might have an answer.

- Q: Can the aluminum sheets be used for manufacturing solar panel frames?

- Yes, aluminum sheets can be used for manufacturing solar panel frames. Aluminum is a lightweight and durable material that is commonly used in the construction of solar panel frames due to its corrosion resistance and high strength-to-weight ratio.

- Q: This question asks for methods to protect aluminum sheets from rusting when exposed to outdoor conditions.

- <p>To prevent rusting of aluminum sheets in outdoor environments, it's crucial to understand that aluminum doesn't rust but forms a thin layer of aluminum oxide, which can darken the surface. To protect aluminum sheets, use protective coatings such as clear anodizing, which enhances the natural oxide layer, or apply a paint or powder coating. Regular cleaning and maintenance can also help in removing dirt and grime that can accelerate the oxidation process. Additionally, using stainless steel fasteners and avoiding contact with dissimilar metals can help prevent galvanic corrosion.</p>

Send your message to us

1 4 Brushed Aluminum Sheets - High Quality Decoration and Roofing Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords