High Quality Aluminum Coil Wholesale for Roofing and Boats - Coated Aluminum Sheet from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of coated aluminum sheet

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

2. Application of coated aluminum sheet

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of coated aluminum sheet

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

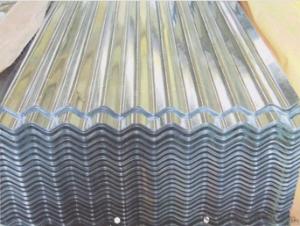

5. Image of coated aluminum sheet

6. Package and shipping of coated aluminum sheet

eye to wall

eye to the wall

with wood pallet

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Is it possible to use an aluminum coil as a paperweight for holding down papers?

- <p>Yes, you can use an aluminum coil as a paperweight. Aluminum is a lightweight and sturdy metal that can effectively hold down papers on a desk. Its weight and shape make it suitable for this purpose. However, ensure the coil is clean and smooth to avoid any damage to the papers or surfaces it comes into contact with. Additionally, consider the size and thickness of the coil to ensure it provides enough weight to keep your papers in place.</p>

- Q: This question asks for an explanation of the distinctions among various grades of hot rolled aluminum coils, focusing on their characteristics and applications.

- <p>Different grades of hot rolled aluminum coils are distinguished by their chemical composition, mechanical properties, and applications. Grades like 1000 series are pure aluminum with high ductility and electrical conductivity, suitable for general purposes. 3000 series, with added manganese, offer moderate strength and are used in cooking utensils and chemical equipment. 5000 series, containing magnesium, are strong and corrosion-resistant, used in marine applications and aerospace. 6000 series, with silicon and magnesium, are known for their mechanical strength and are used in construction and automotive parts. Each grade has specific alloying elements that tailor its properties for different industrial needs.</p>

- Q: I heard that clay pots and aluminum cans are great caves for my fish to breed in but will the can rust???

- Aluminum will not rust. Only iron rusts. Because steel has iron in it, steel can rust.

- Q: This question asks for the current prices of aluminum coil in various regions around the world.

- <p>The price of aluminum coil can vary significantly based on factors such as market demand, supply, transportation costs, and regional economic conditions. Prices are typically quoted per metric ton and are influenced by the London Metal Exchange (LME) and regional metal exchanges. For the most accurate and up-to-date prices, it's best to consult with local metal suppliers or check online commodity trading platforms. Prices can change daily, so real-time data is essential for making informed decisions.</p>

- Q: This question asks for the weight of a single layer of an aluminum coil, which can vary based on its dimensions.

- <p>The weight of a single layer of an aluminum coil depends on its thickness, width, and length. To calculate the weight, you can use the formula: weight = volume 脳 density. The density of aluminum is approximately 2.7 grams per cubic centimeter. If you know the dimensions of the coil, you can calculate its volume and then multiply by the density to find the weight. For example, if the coil has a thickness of 0.1 mm, a width of 1 meter, and a length of 100 meters, the volume would be 0.1 liters or 100 cubic centimeters, and the weight would be approximately 270 kg. However, without specific dimensions, it's impossible to provide an exact weight.</p>

- Q: How are aluminum coils priced in the market?

- Aluminum coils are priced in the market based on several factors. The primary factor influencing the price of aluminum coils is the current market price of aluminum. Since aluminum is a commodity, its price is determined by global supply and demand dynamics, as well as factors like production costs and currency fluctuations. Additionally, the cost of processing and manufacturing aluminum coils also affects their pricing. This includes expenses such as refining, alloying, rolling, and any other specialized processes required to produce the coils. The cost of energy, labor, and raw materials used in the production process also contribute to the overall pricing. Furthermore, market competition and the overall demand for aluminum coils influence their pricing. If there is high demand for aluminum coils and limited supply, the prices are likely to be higher. Conversely, if there is low demand and excess supply, prices may be lower. The size, thickness, and quality of the aluminum coils also play a role in determining their price. Thicker, larger, and higher-quality coils generally command a higher price due to the increased material and processing costs involved. Finally, transportation costs, import/export duties, and taxes imposed by different countries can also impact the pricing of aluminum coils. These additional costs are often factored into the final price of the product. In summary, the pricing of aluminum coils in the market is influenced by the current market price of aluminum, production costs, market competition, demand and supply dynamics, size and quality of the coils, as well as additional costs associated with transportation and taxes.

- Q: Can aluminum coils be used for HVAC condenser coils?

- Yes, aluminum coils can be used for HVAC condenser coils. In fact, aluminum coils have become increasingly popular in recent years due to their numerous advantages over traditional copper coils. Aluminum coils are lighter, more durable, and more resistant to corrosion. They also have excellent heat transfer properties, allowing for efficient cooling of the refrigerant. Additionally, aluminum coils are more cost-effective and environmentally friendly compared to copper coils. Overall, using aluminum coils for HVAC condenser coils is a viable and beneficial option.

- Q: Aluminum roll width 750mm, single layer thickness 6.5mm, diameter 400mm., how to calculate the weight of the aluminum roll?

- You can use the outside diameter, the inner diameter and the width to get the volume. You know the density and volume, and then you can find the weight naturally

- Q: How do aluminum coils contribute to the reduction of carbon footprint?

- Aluminum coils contribute to the reduction of carbon footprint in several ways. Firstly, aluminum is a lightweight material, which means that it requires less energy to transport compared to heavier materials like steel. This reduces fuel consumption and emissions associated with transportation, thereby reducing the overall carbon footprint. Additionally, aluminum is highly recyclable and can be recycled indefinitely without losing its quality. The process of recycling aluminum requires significantly less energy (up to 95% less) compared to producing new aluminum from raw materials. By using aluminum coils, which can be easily recycled, we can reduce the demand for new aluminum production, which in turn reduces the carbon emissions associated with the extraction and refining of raw materials. Moreover, aluminum coils have excellent thermal conductivity properties. This makes them highly efficient for use in heating and cooling systems, such as air conditioning units and heat exchangers. By using aluminum coils in these applications, energy consumption is reduced as they facilitate the transfer of heat more efficiently, resulting in lower energy consumption and reduced carbon emissions. Lastly, aluminum coils have a longer lifespan compared to other materials, such as copper or steel. This means that they require less frequent replacement, resulting in reduced waste generation and lower carbon emissions associated with the manufacturing and disposal of new coils. Overall, the utilization of aluminum coils contributes to the reduction of carbon footprint through its lightweight nature, recyclability, thermal conductivity properties, and longer lifespan. By choosing aluminum coils over other materials, we can make significant strides in reducing carbon emissions and promoting a more sustainable future.

- Q: What are the weight and thickness options for aluminum coils?

- The weight and thickness options for aluminum coils can vary depending on the specific needs and requirements of the project or application. Generally, aluminum coils can range in weight from a few hundred pounds to several thousand pounds, while the thickness can range from a few millimeters to a few inches. It is important to consult with a supplier or manufacturer to determine the appropriate weight and thickness options based on the intended use of the aluminum coils.

Send your message to us

High Quality Aluminum Coil Wholesale for Roofing and Boats - Coated Aluminum Sheet from China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords