Rolled Aluminum Coil for Aluminum Roofing Coated Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Coated Sheet for Aluminium Roofing Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Coated Sheet for Aluminium Roofing:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium Coated Sheet for Aluminium Roofing:

Aluminium Coated Sheet for Aluminium Roofing Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

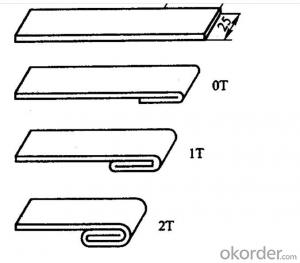

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: How are aluminum coils processed for specific mechanical properties?

- Aluminum coils are processed to achieve specific mechanical properties through a series of manufacturing techniques. These techniques are aimed at altering the structure and composition of the aluminum alloy, ultimately enhancing its desired properties such as strength, hardness, ductility, and corrosion resistance. One common method used to process aluminum coils is heat treatment. This involves heating the coils to a specific temperature and then cooling them rapidly or slowly to achieve the desired properties. For instance, annealing is a heat treatment process that involves heating the coils to a high temperature and then slowly cooling them to enhance their softness and ductility. On the other hand, precipitation hardening involves a combination of solution heat treatment and aging to increase the strength and hardness of the aluminum coils. Another method used to process aluminum coils is cold working or cold rolling. This involves passing the coils through a series of rollers at room temperature to reduce their thickness and improve their mechanical properties. Cold working not only increases the strength and hardness of the coils but can also enhance their surface finish and dimensional accuracy. Furthermore, alloying elements can be added to the aluminum alloy during the casting process to achieve specific mechanical properties. For example, adding elements like copper, magnesium, or zinc can enhance the strength and corrosion resistance of the aluminum coils. In summary, aluminum coils are processed for specific mechanical properties through techniques such as heat treatment, cold working, and alloying. These techniques help modify the structure and composition of the aluminum alloy, resulting in enhanced strength, hardness, ductility, and corrosion resistance.

- Q: Can aluminum coils be customized in terms of thickness?

- Yes, aluminum coils can be customized in terms of thickness. The thickness of aluminum coils can be modified through various manufacturing processes to meet specific requirements and applications.

- Q: Can aluminum coils be used in building facades?

- Yes, aluminum coils can be used in building facades. Aluminum is a popular material choice for building facades due to its numerous benefits. It is lightweight, durable, and corrosion-resistant, making it suitable for exterior applications. Aluminum coils can be formed into various shapes and sizes, allowing for creative and versatile design possibilities. Additionally, aluminum is available in a wide range of finishes, including anodized, painted, and coated, providing further customization options for building facades. Moreover, aluminum is a sustainable material as it is 100% recyclable, making it an environmentally friendly choice for construction projects. Overall, aluminum coils are a viable option for building facades, providing both aesthetic appeal and functional performance.

- Q: Is it safe and effective to use an oven to heat an aluminum coil?

- <p>Yes, you can use an oven to heat an aluminum coil, but with caution. Aluminum has a high melting point and can withstand high temperatures, making it suitable for heating in an oven. However, it's crucial to ensure that the coil is clean and free of any non-stick coatings or residues that could produce toxic fumes when heated. Additionally, monitor the temperature and duration of heating to avoid overheating, which might cause the coil to warp or degrade. Always follow safety guidelines and manufacturer's instructions for your specific oven and aluminum coil.</p>

- Q: What is the typical warranty period for aluminum coils?

- The typical warranty period for aluminum coils can vary depending on the manufacturer and the specific product. However, in general, aluminum coils tend to have warranty periods ranging from 5 to 10 years. This means that during this time, the manufacturer will cover any defects or issues that may arise with the aluminum coils. It is important to note that some manufacturers may offer extended warranty options for an additional cost. Additionally, it is advisable to check the warranty terms and conditions provided by the manufacturer as they may have specific requirements or limitations for the warranty to be valid.

- Q: What are the standard widths of aluminum coils?

- The standard widths of aluminum coils vary depending on the industry and application, but common widths range from 12 inches to 60 inches.

- Q: Are aluminum coils suitable for reflective insulation?

- Yes, aluminum coils are suitable for reflective insulation. Aluminum is highly reflective and has low emissivity, which means it can effectively reflect radiant heat. This makes it an ideal material for reflective insulation, as it helps to reduce heat transfer by reflecting radiant energy away from the insulated space. Aluminum coils are commonly used in reflective insulation products such as foil-faced insulation boards and radiant barriers.

- Q: This question asks for the current market price of aluminum coils.

- <p>The price of aluminum coils can vary significantly based on factors such as grade, thickness, width, and market conditions. As of my last update, prices fluctuate daily due to global supply and demand, economic indicators, and geopolitical events. For the most accurate and up-to-date pricing, it's best to consult with metal suppliers or check commodity exchanges like the London Metal Exchange (LME). Prices are typically quoted in dollars per metric ton and can range from a few thousand to several thousand dollars depending on the aforementioned factors.</p>

- Q: How are aluminum coils processed for specific surface coatings?

- Aluminum coils are processed for specific surface coatings through a series of steps. First, the coils go through cleaning and pre-treatment processes to remove any impurities and ensure proper adhesion of the coating. This step involves degreasing, etching, and rinsing. After pre-treatment, the coils are coated with the desired surface finish using techniques like coil coating or coil painting. This involves applying a layer of paint or coating material onto the surface of the coils using rollers or sprayers. Finally, the coated coils are cured or dried through heat treatment to ensure proper bonding and durability of the surface coating.

- Q: How are aluminum coils used in the production of battery enclosures?

- Aluminum coils are used in the production of battery enclosures as they provide a lightweight and durable material that can be easily molded and shaped to form the enclosure. The coils are typically processed and formed into specific shapes using a combination of heating, rolling, and cutting techniques. This allows for the creation of seamless and tightly sealed enclosures that can protect the batteries from external elements and provide efficient heat dissipation.

Send your message to us

Rolled Aluminum Coil for Aluminum Roofing Coated Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords