Aluminum Roofing Sheets Price for Aluminium Coated Coil - Curtain Wall & Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

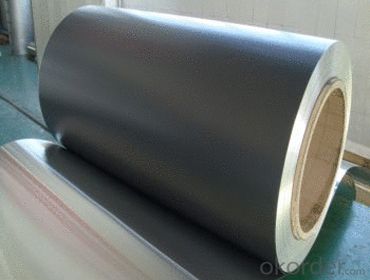

Structure of Aluminium Coated Coil Description:

PE Coated aluminium coils are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.

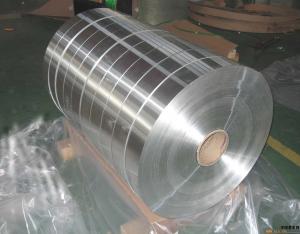

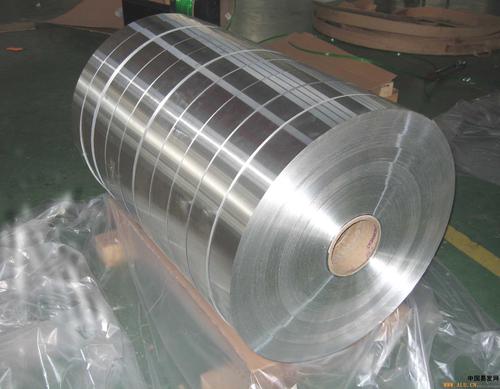

Direct Continuous Aluminium Foil Stock in Coil is one semi-finished aluminium material. This strip can be rolled down to aluminium foil.The final thickess can be 5-20 microns. Aluminium foil is soft, ductile and with a silver-white luster which can be widely used in a large scare of fields.

Main Features of the Aluminium Coated Coil:

Enviromental, light weight, waterproof, fireproof, anti-rust, weather resistance, easy cleaning, easy matching with other decoration materials...

Images of Aluminium Coated Coil:

Aluminium Coated Specifications:

| ALLOY | THICKNESS | TEMPER | HARDNESS | YIELD | SURFACE TREATMENT | ELOGATION |

| 1/3/5XXX | 0.1-1.6MM | O-H112 | 2H | 160 | COATED | 6 |

FAQ of Aluminium Coated Coil:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Can 101 aluminum sheets be used in the production of nameplates or tags?

- Yes, 101 aluminum sheets can be used in the production of nameplates or tags.

- Q: Can aluminum sheets be used for electrical applications?

- Yes, aluminum sheets can be used for electrical applications. Aluminum is a highly conductive material, with nearly 60% of the electrical conductivity of copper. This makes it suitable for various electrical applications such as wiring, bus bars, transformers, and electrical panels. Aluminum sheets are commonly used in the construction of electrical enclosures and housings due to their lightweight and corrosion-resistant properties. Additionally, aluminum is cost-effective compared to other metals like copper, making it a popular choice in many electrical applications.

- Q: the aluminium pull tabs are in a jucy juice bottle

- So saving pull tabs isn't a complete waste of time. But let's make one thing clear: *there's nothing special about pull tabs*. You'd save yourself a heap o' trouble and make a lot more money if you recycled the whole can. The Reynolds and kidney foundation people have tried to get that point across with a poster showing a red Ghost busters-type slash through a cartoon of someone trying to detach a pull tab from a can. The headline says, Keep Tabs on Your Cans. But the public hasn't gotten the message. Supposedly responsible people -- e.g., the honchos at your school -- will organize pull tab collection drives without even bothering to get the whole story. Urban legends expert Jan Brunvand reports that in 1989 a Minneapolis VFW post organized a pull tab collection drive for the local Ronald McDonald House. When Brunvand asked the organizers why they didn't tell people to save whole cans, they lamely replied that there were hygiene problems and that people liked mailing in the tabs, even though the postage often exceeded the value of the aluminum. In other words, it's not important to *do* good as long as people *feel* good. Sometimes I don't think we have enough common sense in this country to fill a teacup.

- Q: What are the standard tolerances for aluminum sheets?

- The tolerances for aluminum sheets differ based on the specific industry and application. However, there are commonly accepted tolerances for aluminum sheets, such as thickness tolerances, flatness tolerances, and width and length tolerances. Thickness tolerances pertain to the allowable variation in the thickness of an aluminum sheet. The range of these tolerances depends on the grade and thickness of the sheet, and can be from +/- 0.005 inches to +/- 0.010 inches. Flatness tolerances specify the acceptable degree of flatness or deviation from a perfectly flat surface for an aluminum sheet. The range of flatness tolerances varies according to the application's specific requirements, and can be from a few thousandths of an inch to a few hundredths of an inch. Width and length tolerances define the allowable variation in the dimensions of an aluminum sheet. These tolerances can be expressed as +/- inches or as a percentage of the sheet's width or length. Generally, width and length tolerances for aluminum sheets fall within the range of +/- 0.25 to +/- 0.50 inches. It is important to note that these standard tolerances are subject to change and may differ depending on the specific industry, customer requirements, and the manufacturer's capabilities. Therefore, it is advisable to consult the manufacturer or industry-specific standards to determine the exact tolerances for aluminum sheets in a particular application.

- Q: I may use the copper or brass for an inlay on a decorative piece of aluminum I'm working on.....

- This Site Might Help You. RE: which has the lower melting temperature....aluminum, copper, or brass...can you list all 3? I may use the copper or brass for an inlay on a decorative piece of aluminum I'm working on.....

- Q: Can aluminum sheet be used for aerospace applications?

- Yes, aluminum sheet can be used for aerospace applications. Aluminum is a lightweight metal with good strength-to-weight ratio and excellent corrosion resistance, making it an ideal choice for aerospace components such as aircraft skins, wings, and structural parts.

- Q: What are the different methods of surface etching aluminum sheets?

- There are several different methods for surface etching aluminum sheets, each with its own advantages and specific applications. Some of the most common methods include chemical etching, laser etching, and mechanical etching. Chemical etching involves using a chemical solution to selectively remove the surface of the aluminum sheet. This method is highly precise and can achieve intricate designs or patterns. It is often used for decorative purposes, such as creating logos or artwork on aluminum signage or nameplates. Additionally, chemical etching can be used to create functional features, such as improving adhesion for paint or coatings. Laser etching, on the other hand, uses a high-powered laser to remove material from the surface of the aluminum sheet. This method is extremely precise and can create very fine details. It is commonly used for marking or engraving aluminum sheets, such as serial numbers, barcodes, or product identification. Laser etching is also a non-contact process, which means it does not cause any physical damage to the sheet. Mechanical etching, or abrasive blasting, involves using an abrasive material to physically remove the surface of the aluminum sheet. This method is typically used for larger-scale applications, such as creating a textured or matte finish on aluminum panels or sheets. Mechanical etching can also be used to remove any surface imperfections or contaminants, preparing the aluminum sheet for further processing or finishing. In summary, the different methods of surface etching aluminum sheets include chemical etching, laser etching, and mechanical etching. Each method offers unique advantages and is used for specific applications, ranging from decorative designs to functional markings or surface treatments.

- Q: What are the different cutting tools used for aluminum sheets?

- There are several cutting tools that can be used for aluminum sheets. 1. Circular Saw: A circular saw with a carbide-tipped blade can be used to cut aluminum sheets. It is important to use a blade with fine teeth to ensure a clean and smooth cut. 2. Jigsaw: A jigsaw equipped with a metal-cutting blade can also be used to cut aluminum sheets. This tool allows for more intricate cuts and curves. 3. Bandsaw: A bandsaw with a fine-toothed blade is another option for cutting aluminum sheets. It provides a straight and precise cut, making it ideal for larger or thicker sheets. 4. Shears: Electric or manual shears can be used to cut aluminum sheets. They are particularly useful for straight cuts and can achieve a clean finish. 5. Plasma Cutter: A plasma cutter can be used for cutting aluminum sheets, especially for thicker materials. It uses high-temperature plasma to melt through the metal, resulting in a precise and efficient cut. 6. Laser Cutter: Laser cutting machines are commonly used for cutting aluminum sheets. They produce a high-powered laser beam that melts and vaporizes the material, allowing for precise and intricate cuts. It is important to wear appropriate safety gear, such as gloves and goggles, when using any of these cutting tools. Additionally, choosing the right tool depends on the thickness of the aluminum sheet and the desired cut. It is recommended to consult a professional or refer to the manufacturer's guidelines for the specific tool being used.

- Q: Can aluminum sheets be bent or formed into different shapes?

- Yes, aluminum sheets can be bent or formed into different shapes. Aluminum is a highly malleable metal, which means it can be easily shaped or formed without breaking or cracking. This property makes it highly versatile for various industries and applications. Aluminum sheets can be bent, rolled, or pressed to create different shapes or forms, such as cylinders, cones, or complex geometric structures. The ability to bend or form aluminum sheets opens up a wide range of possibilities for manufacturing, construction, automotive, aerospace, and many other industries.

- Q: Can aluminum sheets be used for electrical enclosures?

- Yes, aluminum sheets can be used for electrical enclosures. Aluminum is a widely used material in the electrical industry due to its excellent conductivity, lightweight nature, and corrosion resistance. It provides a durable and reliable solution for protecting electrical components and ensuring proper functioning of the enclosure.

Send your message to us

Aluminum Roofing Sheets Price for Aluminium Coated Coil - Curtain Wall & Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords