CMAX Galvanized Cuplock Scaffolding System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Galvanized Cuplock Scaffolding System Description

What is Cuplock Scaffolding system

Cuplock Scaffolding system is also called Modular Scaffolding and Multidirectional Scaffolding, the junction enables quick and easy connection of load bearing items as well as reinforcing parts to each other with an enormous rigidity. Galvanized Cuplock Standard is a tube of D48*3.5mm which material is Q235/Q345B, Ledger is made by a tube with two cup welded on the ends separatel

Function of the Cuplock Scaffolding system

Cuplock scaffolding is the new generation product of sacffolding.. Scaffold vertical is a tube of D48*3.5mm which material is Q235/Q345B. On the vertical welded many cups every specific distance used to jonit the posts. On the bottom of vertical post is a base collar used to connect the scaffolding and the ground. Ledger is made by a tube with two blade welded on the ends separately

Advantage of Cinglock Scaffolding system

Strong ability of resistance to deformation, for different manufacturing process, It can resistant deformation, ensure the product safety and effective use of repeated; Strong anti-sliding performance, joint area is large, fasteners and overcomes the cast iron steel tube a point or line defect of joint, remove of steel pipe slip hazard.

2. Main Features of Galvanized Cuplock Scaffolding System

- Reliable performance

- Corrosion resistance

- Durable finish standards

- Strong anti-sliding performance

- Manugacture

- We can special design according to any requirements.

3. Galvanized Cuplock Scaffolding System Specifications

Raw Material: Q345

Size: 500-3000 mm or customer demanded

Certifies:, Element

Technology : Forging / welding

Surface treatment: Electro galvanized, Hot DIP galvanized, or painted

Brand Name:FF

Useage: connecting the scaffolding pipe

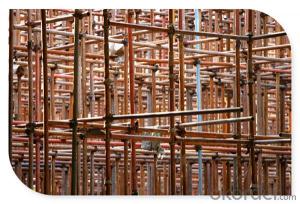

4. Galvanized Cuplock Scaffolding System Images

5. FAQ of Galvanized Cuplock Scaffolding System

1) What can we do for you?

- We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

- We can provide you the professional design team.

- We can provide fashionable and newest styles for you.

- We can design the artwork for you.

- Please feel free to customize.

2) What promises can be done by us?

- If interested in Timber-beam Formwork, please feel free to write us for any QUOTE.

- If printing required, please advise asap because the whole set need much more time to complete.

- Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about the package and shipping time?

- Packing: As Customer's Requirements

- Shipping: We have various shipping ways for our customers, such as express, by air/ sea etc.

- Shipping time: Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

- Q: am i in my rights not to allow the scaffolding to be brought through my living room and kitchen.I have just had a threatening letter from camden council that they will force an entry if I refuse.I have lived here for 33 years and any scaffolding has always gone through the side entrance next door and over the garden wall I am a pensioner and feel I am being harassed

- Hey teanzette, I see you're a big fan of gardening and that you really love to plant different plants with that desired passion <3 I just find this awesomely great gardening guide online couple of days ago, and I must say that my garden are just looking more and more fabulous each day!! :D My guests and family always complimenting. I keep it a secret tho, since I like being looked at as this master gardener :) so shhhhh.. don't tell anyone! xD hehe But I will give you the link, my friend :) And cook luck!

- Q: I just got my scaffold piercing yesterday, (the bar through the top of your ear) and one side is kind of swelling. Is that okay, or normal?

- this is real, in spite of the undeniable fact that it is a good worse concept to have an commercial achieved with rings. this is by using the fact your physique can pass your piercings extremely, to handle the perspective that works maximum suitable on your physique. usually, that isn't a bad element, yet with industrials, this is a situation. you may discover that an commercial healed with rings would possibly no longer accommodate a bar properly; the piercing might heal unaligned, and donning a bar could be painful or impossible. Plus any save that thinks changing from rings to a bar at 6 to eight weeks will make any distinction from getting a bar initially, you mustn't have faith to poke needles in you. Industrials take 6 months to a year or extra to heal. At 8 weeks, the piercings are nevertheless very lots therapeutic. So in case you have your rings switched at that factor, you would be stressful the piercing, placing back therapeutic, and you will could manage each and all the rigidity and hypertrophic scarring issues besides. It in certainty comes right down to this, industrials suck to heal. Bars are difficult to heal. yet rings will often bring about undesirable commercial placement and alignment. in basic terms get pierced with a bar and manage the matters as they arrive. it is nevertheless very lots a danger to heal an commercial, it in basic terms takes time, persistence, and an exceedingly stable piercer (and prefer I reported come across a extra beneficial save, whoever advised you it would artwork to alter the jewellery from rings to a bar at 8 weeks is an fool).

- Q: I would like to ask the bowl buckle scaffold operating layer is what?

- The second is the external wall, the use of steel pipe scaffolding, such as structural decoration, which is divided into single and double scaffolding, double row with landing and cantilever.

- Q: Help.Saturday I want to get a snug piercing but apparently it really hurts I had my scaffolding(industrial) done about 4 months ago it hurt but not that much I was just wanted to know if any one knows if it really hurts I have had alot of piercings but I'm really worried about this one :/Just wanted to know if any1 has any ideas on pain or had both of them ??

- A snug is nothing compared to an industrial, you'll be totally fine. Good luck!

- Q: What is the difference between the bowl buckle scaffold and the fastener type steel pipe scaffold? What is the difference

- . Its main function is to protect. Specific reference to JGJ 1302011 "construction fastener type steel pipe scaffolding safety technical specifications" in the relevant instructions, and illustrations.

- Q: Bridge formwork support bowl button steel scaffolding, you need to set the floor bar?

- Bridge formwork support bowl buckle type steel pipe scaffold, need to set the sweeping rod.

- Q: a. Climb the stairs to join Hester and Pearl. b. Give an encore sermon. c. Reveal the meaning of life. d. Rise Up to heaven.

- e. do his own homework Only joking. It's definitely d. Or c.

- Q: Bowl buckle scaffold construction needs to pay attention to what problems

- Arrange training for the erection of timberman. ?Set up, when the demolition of the establishment of warning signs, assigned to monitor. ?Erection is completed, after acceptance of the listing.

- Q: Why does this discovery both confuse and frighten her?quot;The Scarlet Letterquot;

- her husband, he has been in England while she was in America for a year or 2 can't remember; I think she thought he was dead or not coming cannot remember. It frightens her because she has a kid that cannot be his.

- Q: What does it mean in the phrase that one can have toxic people in their life and still maintain stability as long as we build a scaffolding?

- As long as you have a firm structure of friends and family around you (like scaffolding round a construction site or building) you can withstand the presence of harmful, toxic people.

Send your message to us

CMAX Galvanized Cuplock Scaffolding System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords