Chinese Pre-Painted Galvanized/Aluzinc Steel Coil with Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

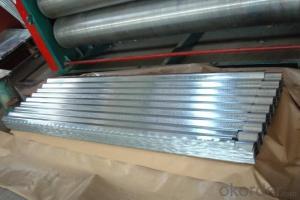

1. Chinese Pre-Painted Galvanized/Aluzinc Steel Coil with Best Quality

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What are the safety precautions while handling steel coils?

- When handling steel coils, it is important to follow certain safety precautions to prevent accidents and injuries. Here are some key safety measures to consider: 1. Personal Protective Equipment (PPE): Always wear appropriate PPE such as steel-toed boots, safety glasses, gloves, and a hard hat. PPE will protect you from potential hazards, including falling objects, sharp edges, and flying debris. 2. Training and Proper Lifting Techniques: Ensure that workers involved in the handling of steel coils have received proper training on safe lifting techniques. This includes using the legs to lift, keeping the back straight, and avoiding twisting motions. Proper lifting techniques reduce the risk of back strains and injuries. 3. Secure Storage and Stacking: When storing or stacking steel coils, make sure they are placed on a level and stable surface. Use appropriate storage equipment such as racks or pallets to prevent coils from shifting or falling. Securely stack the coils to avoid toppling or collapsing. 4. Inspection and Maintenance: Regularly inspect steel coils for any defects, such as sharp edges, loose bands, or damaged packaging. Avoid handling coils that appear damaged or unstable. Maintenance of equipment, such as forklifts or cranes, used for moving the coils should be regularly conducted to ensure safe operation. 5. Communication and Signaling: Implement clear communication and signaling protocols between workers involved in handling steel coils. This can include hand signals or radio communication to coordinate movements and prevent accidents, especially in areas with restricted visibility. 6. Load Limits and Capacity: Be aware of the load limits and capacity of the equipment being used to move steel coils, such as forklifts or cranes. Overloading equipment can lead to instability, tipping, or collapse, increasing the risk of accidents and injuries. 7. Proper Lashing and Securing: When transporting steel coils, use appropriate lashing and securing methods to prevent movement or falling during transportation. This may include using straps, chains, or other restraints to keep the coils in place. 8. Emergency Preparedness: Have an emergency plan in place in case of accidents or injuries. Ensure that workers are trained in first aid and that emergency response equipment, such as fire extinguishers and first aid kits, are readily available. By following these safety precautions, the risk of accidents and injuries while handling steel coils can be significantly reduced, creating a safer work environment for all involved.

- Q: Can steel coils be customized in terms of size and shape?

- Yes, steel coils can be customized in terms of size and shape. They can be manufactured to specific dimensions and configurations according to the requirements and specifications of the customer.

- Q: I want to start getting throwing knives and i was wondering what material is best for quality, but still cheap. I also saw some 440 stainless steel knives that i liked and wanted to know if the material was good

- Good steel ain't cheap, cheap steel ain't good... If you're just starting out (practicing anyways), I would be less concerned about the material and more concerned about the style and shape of the blade to gain consistency in your technique... When you start getting proficient for competitions and such... then I'd start investigating steel grades... Anyways, here's a summary from the wiki: Type 440—a higher grade of cutlery steel, with more carbon, allowing for much better edge retention when properly heat-treated. It can be hardened to approximately Rockwell 58 hardness, making it one of the hardest stainless steels. Due to its toughness and relatively low cost, most display-only and replica swords or knives are made of 440 stainless. Available in four grades: 440A, 440B, 440C, and the uncommon 440F (free machinable). 440A, having the least amount of carbon in it, is the most stain-resistant; 440C, having the most, is the strongest and is usually considered more desirable in knifemaking than 440A, except for diving or other salt-water applications.

- Q: can anyone help me to find any webpage about lists/types of stainless steel?

- Types of stainless steel There are over 150 grades of stainless steel, of which fifteen are most common. The AISI (American Iron and Steel Institute) defines the following grades among others: - 200 Series—austenitic iron-chromium-nickel-manganese alloys - 300 Series—austenitic iron-chromium-nickel alloys Type 301—highly ductile, for formed products. Also hardens rapidly during mechanical working. Type 303—free machining version of 304 via addition of sulfur Type 304—the most common; the classic 18/8 stainless steel Type 316—Alloy addition of molybdenum to prevent specific forms of corrosion - 400 Series—ferritic and martensitic alloys.

- Q: I just purchased this Benchmade knife with m390 steel blade and it cost me a fortune but I wanted to know if this new steel is a tool steel. what classifies a tool steel. M390 = 1.9 carbon, 20. chromium, .30 manganese, 1. molybdenum, .60silicon, .60 tugsten, 4. vanadium at 60-62 HRC

- Congratulations you can read a table of steels. Yes M390 is a tool steel. Blades is one application as is the manufacture of injection moulding tools.

- Q: How are steel coils priced and traded in the market?

- Steel coils in the market are priced and traded based on a variety of factors. The primary determinant is the current dynamics of supply and demand in the steel industry. When demand for steel coils is high, prices tend to increase, and vice versa. The cost of raw materials, such as iron ore and coal, is another crucial factor in determining the price of steel coils. Fluctuations in the prices of these materials can directly impact the pricing of steel coils. Furthermore, the price of steel coils is influenced by their quality and specifications. Coils with desirable characteristics, such as strength, corrosion resistance, or surface finish, may command a higher price in the market. Steel coils are traded through different platforms, including physical exchanges, futures contracts, and over-the-counter (OTC) markets. Physical exchanges allow buyers and sellers to trade steel coils by exchanging physical deliveries. Futures contracts, on the other hand, enable traders to buy or sell steel coils at a predetermined price and future date, providing a way to hedge against price fluctuations. The OTC market provides an alternative avenue for trading steel coils, where buyers and sellers negotiate and agree on prices directly without involving a formal exchange. This allows for flexibility and customization in trading, catering to specific requirements. In conclusion, the pricing and trading of steel coils in the market are influenced by factors such as demand and supply dynamics, raw material costs, quality specifications, and the availability of different trading platforms. It is a complex process that requires careful consideration of various factors to determine fair prices and facilitate efficient trading.

- Q: What are the different types of steel coil surface treatments for outdoor applications?

- For outdoor applications, there are several commonly used surface treatments for steel coils that enhance durability, corrosion resistance, and appearance. Examples of these treatments include: 1. Galvanized: This treatment involves applying a layer of zinc to the steel surface, providing excellent corrosion resistance. Galvanized steel coils have a shiny, silver appearance. 2. Galvalume: Galvalume is a combination of aluminum and zinc applied to the steel surface, offering superior corrosion resistance compared to galvanized steel. Galvalume steel coils have a duller, matte finish. 3. Painted: Steel coils can be painted with various coatings to enhance appearance and protect against corrosion. The paint can be applied in single or multiple layers, depending on the desired level of protection. Painted steel coils are available in a wide range of colors and finishes. 4. Powder Coated: This type of paint coating is applied as a powder and then cured under heat, resulting in a durable and long-lasting finish. Powder coated steel coils are resistant to chipping, scratching, and fading, making them suitable for outdoor applications. 5. Organic Coated: Organic coatings, such as PVC or PVDF, are applied to steel coils to provide additional protection against corrosion and weathering. These coatings are commonly used in architectural applications where aesthetics and durability are important. These various surface treatments for steel coils offer different levels of protection and aesthetic options for outdoor applications. The choice of treatment depends on factors such as the intended use, environmental conditions, and desired appearance.

- Q: How are steel coils used in the production of electrical resistors?

- Steel coils are used in the production of electrical resistors as the core material for winding wire around. The coils provide a stable structure, allowing the wire to be tightly wound and creating the necessary resistance for regulating electric current flow.

- Q: What are the safety precautions when handling steel coils?

- When handling steel coils, it is important to follow several safety precautions. First and foremost, workers should wear appropriate personal protective equipment (PPE) such as safety gloves, safety glasses, and steel-toed boots to protect themselves from potential injuries. Secondly, it is crucial to ensure that the area is clear of any obstructions or tripping hazards to prevent accidents. Additionally, workers should receive proper training on safe lifting techniques and use of lifting equipment to avoid strain or back injuries. It is also recommended to inspect the coils for any sharp edges or protruding objects before handling them. Lastly, communication and teamwork are essential to ensure the safe handling and maneuvering of steel coils, especially when using heavy machinery or cranes.

- Q: What are the common coil storage methods?

- The common coil storage methods include stacking coils vertically, using coil cradles or racks, and storing them horizontally on pallets or on the ground.

Send your message to us

Chinese Pre-Painted Galvanized/Aluzinc Steel Coil with Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords