Ceramic Fiber Blanket Module for Cement Rotary Kiln Insulation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Fiber Module for Cement Rotary Kiln Insulation

Composite of Ceramic Fiber Module for Cement Rotary Kiln Insulation

Ceramic Fiber Module for Cement Rotary Kiln Insulation is made from high quality clay, high

purity alumina and silica oxides by spun or blown process.

Ceramic Fiber Module for Cement Rotary Kiln Insulation: ordinary type, standard form, high-purity type, high-alumina type and containing zirconium type. Different types of products used different materials. Performance of Ceramic Fiber Module for Cement Rotary Kiln Insulation also has difference, and they are suitable for different working temperatures.

Main Features of the Ceramic Fiber Module for Cement Rotary Kiln Insulation

◆Low thermal conductivity

◆High tensile strength

◆Resilient to thermal shock

◆Corrosion resistance

Application of Ceramic Fiber Module for Cement Rotary Kiln Insulation

◆Petrochemical process heater refractory fiber lining

◆General furnace backup insulation

◆Heat treating furnace or intermittent(shuttle) kiln hot face lining

◆Electrical insulator

◆Heat seals for kiln car or furnace door

◆High temperature acoustic

◆Fire protection

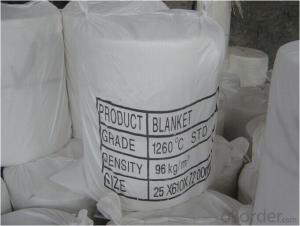

Ceramic Fiber Module for Cement Rotary Kiln Insulation Images

Ceramic Fiber Module for Cement Rotary Kiln Insulation Specification

Type | STD | HP | HA | HZ | |

Classification Temperature (°C) | 1260 | 1260 | 1350 | 1430 | |

Working Temperature (°C) | 1050 | 1100 | 1200 | 1350 | |

Color | Spotlessly white | spotlessly | spotlessly | spotlessly | |

white | white | white | |||

Density (kg/m3) | 160-200 | 160-200 | 160-200 | 160-200 | |

Shrinkage on heating (%) | -3 | -3 | -3.5 | 3.5 | |

(24 hours, density as 128/m3) | (1150°C) | (1250°C) | (1300°C) | (1350°C) | |

Thermal conductivity by different temperature (w/m.k) (density as 128kg/m3) | 0.15(800°C) | 0.176(800°C) | 0.18(1000°C) | 0.23(1000°C | |

0.17(1000°C) | 0.22(1000°C) | 0.26(1200°C) | 0.31(1200°C) | ||

Tensile strength (MPa) | 0.04 | 0.04 | 0.04 | 0.04 | |

(density as 128kg/m3) | |||||

Chemical | AL2O3 | 45-47 | 45-46 | 53-55 | 38-54 |

composition | AL2O3+SIO2 | 98.5 | 99 | 99 | 82-90 |

(%) | ZrO2 | - | - | - | 10-18 |

FAQ of Ceramic Fiber Module for Cement Rotary Kiln Insulation

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q6:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

- Q: Hi all, Mums on a trip to Europe, and she's stopping in Thailand on the way, so we need to know what the temperature is during the day and eveningShe doesn't want to go overdressed, or be freezing when she gets thereThanks all

- Use both a rub and sauceYou put the rub on them, wrap them in foil and bake them at 250 for several hours, I cook them for 7-8 hrs myselfI tried 5 hrs once and they were not nearly as tender Take them out of the oven and cut the rack into sections of 4-6 ribs eachPut these sections on the grill and slather them with BBQ sauceYou just grill them long enough to get the nice grilled smoky flavor.

- Q: Recently i forced one of my hard stools out and it seems to have caused my anus to bleedI have been trying to eat less to poo less and eat high fibre foods but i still seem to be pooing along with bloodIt just seems as though the problem wont heal if i poo each timeIs this anal fissure and what can I do? Will there be side effects to my body is I lose blood every time i poo?Proper answers only rather than quot;visit your doctorquot; because i already know that and would like another opinion

- Union pay scales vary union to union, but most likely it will be around the same rate

- Q: I'm on a new, healthy, high-fiber diet and I feel great after two or three days on the dietMy typical day's meal consists of a large bowl of high-fiber cereal for breakfast, soup, assorted nuts, and natural popcorn for lunch with plain yogurt w/ granola for dessertThen, for a mid-afternoon snack I may have a Yoplait whips or some cheeseThen, some whole wheat pasta with veggies and applesauce is a dinner favoriteI also drink about six glasses of waterBut I always feel hungry, any tips on filling high-fiber foods? Thanks )

- I have the 1 3/4 one and I love it, my work had the smaller one and I didn't like it, it took longer for me to straighten my hairSo get the bigger one(my hair is long though)

- Q: How do I 'make at home' my own sound deadening material for my car without spending money on dynamat?

- Fiberglass or foam rubberThe air pockets in either one absorb and insulate soundThe thicker the betterCork works well tooThe cheapest way would be to make a fiber comforter of some sort, like a thick blanket, but it would hold moisture and rot that's not good unless you could keep it dry somehow!

- Q: We bought a beautiful home in October, but didnt realize this house only has about 1 1/2 quot; of roll fiberglass insulation in the walls and ceilingNeedless to say, its freezing in here and our propane bill is upwards along $800 a monthWe have to insulate before next winterIs it possible to insulate without removing the drywallI thought maybe we could spray foam in or blow in some kind of insulationAny suggestionsI would rather not consider re drywallingHelp.

- Both will not be accurate due to difference in temperatureAlso depends upon what is the allowable toleranceMay be you will be able to correct the results for the expansionThen materiel doesnt matter

- Q: I am remodeling my living room and pulled down a ceiling that exposed an old porch roof made from 2X4's on 22 inch centersThere was R30 insulation on top of the ceiling that I pulled down and I want to leave the vaulted ceiling and cover it with 1X8 TGI know I need to put insulation between the roof joists but I don't think I can get the same R30 (needs at least 9-10 inches?) in the 2X4 space.What is my best options to get the maximum R value in my ceiling?

- Sparking first , then burn the plastic inside, and then blow the microwave fuse insideAfter that happen, your microwave oven lost about 40% of its cooking power due to overloaded its magnetron.

- Q: ok i have avon flat iron and it really gives me straight hair but after abt an hour like 23%of my hair is flipping outwards!!!how will i make it last-long??

- Design engineer is a general term that covers multiple engineering disciplines: Electrical, mechanical and civil engineering are the basic threeThe design engineer is distinguished from the designer/drafter by virtue of the fact that a design engineer sets the direction of the design effortThe design engineer usually leads the project, directing the designer/drafter as necessaryHe/she works with industrial designers and marketing to develop the product concept and specifications and directs the design effort from that pointThe design engineer may direct a team of designers to create the drawings necessary for prototyping and production, or in the case of buildings, for constructionHowever, with the advent of CAD and solid modeling software (Autodesk Inventor, SolidWorks, Pro/ENGINEER, Catia, etc, for example) the design engineer may create the drawings him or herselfThe next responsibility of many design engineers is prototypingA model of the product is created and reviewedPrototypes are usually functional and non-functionalFunctional prototypes are used for testing and the non-functional are used for form and fit checkingThis stage is where design flaws are found and corrected, and tooling, manufacturing fixtures, and packaging are developedOnce the prototype is finalized, after many iterations, the next step is preproductionThe design engineer, working with a manufacturing engineer and a quality engineer reviews an initial run of components and assemblies for design complianceThis is often determined through statistical process controlVariations in the product are correlated to aspects of the process and eliminatedThe most common metric used is the process capability index CpkA Cpk of 1.0 is considered the baseline acceptance for full production go-aheadThe design engineer may follow the product and make requested changes and corrections throughout the life of the productThis is referred to as cradle to grave engineering.

- Q: I have been debating whether or not to buy themI don't know anyone that has bought themI have alot of clothes, sheets, blankets, and fabricI wanted to use them to make room in my basementDo they really work?

- The aluminum is just the newer modelI have the white one, its plenty fast for what you want it for.

- Q: Should I attempt to clean the wool? If so, how? My neice is a hand spinner and will get the woolI don't want to mess it up by turning it into felt!

- Yes I suppose I've had my retro days before retro was coolThese days I still wear bell bottom jeans sometimes, and sweatshirts are still in fashionSince I don't care for many of the newer styles out for the last 30 years , I stick to many of the older styles when it comes to dresses, skirts, jeans and such.

- Q: which vegetables and fruits are high in either fiber or vitamin C or both?And is there any meats or fish high in either one of these?

- For wool sock yarn (fingering weight) you want something with at least 20 to 25% polyamide (nylon) in it for two reasons, first, the nylon helps to keep the yarn from wearing excessively at the heels, ball of the foot and toes, and second, it usually means the yarn is superwash and can safely go in the washer, although it should be dried on the line (depending on the brand, it can go into the dryer, but some brands of yarn, notably Lorna's Laces Shepherd Sock will felt somewhat in the dryer)A 50 gram weight ball (somewhere between 175 and 200 or so yards of yarn) is enough for a sock for an adult woman, so you need two balls for a pairA man's sock needs more yarn, so 3 50 gram balls will work for thatA 100 gram ball (around 400 yards) will make a woman's pair, or a pair and a half for a childGood brands are Regia, Opal, Lorna's Laces, Brown Sheep Wildefoot (I've knit socks from all of these as well as Dale of Norway Baby Ull) and the socks have worn well for years (yes, I wear my socks all year round)If you want a worsted weight yarn for thick socks, go to Cascade 220 Superwash (trust me, non-superwash wool felts in the washer and dryer, which is why my DH is very leery when he does laundry and sees my socks in there-he's felted more than one pair of mine)Charlotte Schurch's sock books are a good place to start learning sock knittingYour library can get it if you don't have it.

Send your message to us

Ceramic Fiber Blanket Module for Cement Rotary Kiln Insulation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches