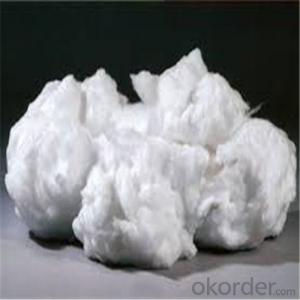

Ceramic Fiber Bulk Insulation for Insulating Lining

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

Common Fibre: With hard clay clinker as raw material, made from melting,blowing,spun by the resistance furnace.

High purity Fibre: With high purity alumina and silica as raw material, made from melting,blowing,spun by the resistance furnace.

Cerachem Fibre: With alumina,silica and zirconia as raw material, made from melting,blowing,spun by the resistance furnace.

Cerachrome Fibre: With alumina,silica and chromia as raw material, made from melting,blowing,spun by the resistance furnace.

Spun Fibre: Contain lubricant ,low residue ball content,high fibre material content, and spun without processing turns to be long fibre, is the gap fillers of wall lining of high temperature kiln heating device and raw material for yarns

Blowing Fibre: No lubricant,no processing,low residue ball content, is the gap fillers of high temperature kiln, and raw material for vacuum forming products, fibre spray, fibre paper

Features

Excellent thermal stability, resist devitrification at high temperature.

Low heat strong capacity, Low thermal conductivity

Contain no binders or corrosive agents

Resilient up to high temperatures

Excellent sound absorber

Typical Application

Raw material for the manufacturing of finished products such as boards, paper, shapes, yarns etc

Packing expansion joints and material for temporary repair of insulation

Raw material for Fiber spraying,castable and daub material

Loose insulating fill for complex spaces and areas where access is difficult

Date sheet

Type | CT 1100 | CT 1260 | CT 1360 | CT 1430 | CT 1500 | |

Classification Temperature(°C) | 1100 | 1260 | 1360 | 1430 | 1500 | |

color | white | Pure white | Pure white | Pure white | Blue/green | |

Fiber diameter(um) | blowing | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 |

spun | 3-4.5 | 3-4.5 | 3-4.0 | 3-4.0 | 3-4.0 | |

Chemical Composition(%)

| Al2O3 | 42-44 | 45-46 | 52-55 | 39-40 | 43 |

Al2O3+SiO2 | 96 | 98 | 99 | 99 | 99 | |

ZrO2 | - | - | - | 15-17 | - | |

Cr2O3 | - | - | - | - | 2.5-3.0 | |

Remark

The values given herein are typical average values obtained in accordance with accepted test methods and are subject to normal manufacturing variations. They are supplied as a technical service and are subject to change without notice. Therefore, the data contained herein should not be used for specification purposes.

FAQ

Q3: What other products does OKorder offer?

A3: We offer a full range of refractory bricks, monolithic material, ceramic fiber products, and more.

Q4: If I need your offer, what information do you need?

A4: In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

- Q: What are the main differences between an ordinary furnace and a ceramic fiber furnace?

- Service life: ordinary furnace quenching, sudden heat, easy to cause blasting chamber or cracking, shorten service life, ceramic fiber furnace without blasting chamber or crack possible.There are two common practices in ceramic fiber furnaces:The first is a larger furnace, which is fixed on the furnace wall with ceramic fiber modules;The second is a small furnace, the manufacture of abrasives, direct pouring, or with punch milling machine processing ceramic fiber board.

- Q: What is the density of ceramic fiber modules? The best insulation effect

- Ceramic fiber module density in 200-220, the first production of ceramic fiber module is generally made of ceramic fiber blown blanket, fiber blown blanket fine short, ceramic fiber module is made out of the expansion is relatively stable, but in recent years because of the cost of production, the majority of ceramic fiber module are thrown silk do relatively, the tensile force is big, according to your own combustion atmosphere of furnace temperature and heating module and intracranial, select the density and thickness of the ceramic fiber module. Just make the insulation layer, then recommend 200kg/ cubic meters. Ring fire-resistant insulation materials company has a specific index and design analysis.

- Q: Should the ceramic fiber furnace be compacted?

- The simplest, the least durable method, uses ceramic fiber blankets for wrapping, which is often caused by the poor density of the ceramic fiber blanket and the lack of anchorage

- Q: What is the difference between the ceramic fiber cloth and the high silicon oxygen cloth?

- High temperature is similar to that of strength, service life, the price is high silica cloth. High silica fabric belongs to glass fiber.

- Q: Glass fiber cotton, aluminum silicate cotton, rock wool, what's the difference between these three?

- Rock wool: is a kind of insulation materials, widely used in exterior wall insulation, because rock wool dust carcinogenicity, the state has banned the use of industry.

- Q: What is the diameter of the ceramic fiber? How to mix?

- The diameter of the general ceramic mineral fiber is 2---5 microns, and the length is in the range of 0---8 mm long.Ordinary mixing machine can be easily mixed, and the mixture of other good affinity, evenly dispersed and mixed resin or rubber and liquid glue, thus make the fiber products look pretty smooth, bright color, anti impact friction resistance, small abrasion, tensile Xinghao, can effectively reduce the noise without damage dual, can reduce the amount of metal fiber.

- Q: What is the good heat insulation effect of glass fiber and aluminum silicate fiber, what are their respective advantages and disadvantages?

- Advantages and disadvantages of aluminum silicate fiber: high temperature insulation, heat preservation, fire resistance, noise reduction, insulation, light weight. Disadvantages: compressive resistance, bending force is relatively poor, easy to produce dust, waterproof performance is not very good.

- Q: The difference between the ceramic fiber blanket and rock cotton blanket

- Ceramic fiber lining: low thermal conductivity of ceramic fiber lining in the average temperature of 400 degrees, the thermal conductivity is less than 0.1w/mk, the average 600 degrees less than 0.l5 w/mk, average 1000 degrees less than 0.25w/mk, about l/8 as a lightweight clay brick, lightweight refractory lining l/10, adiabatic effect.The construction of ceramic fiber lining is simple: no expansion joints are needed during construction, and the construction personnel can be started after the basic training. The technical factors of construction have little influence on the insulation effect of the lining.

- Q: Aluminum silicate needle carpet and ceramic fiber insulation performance of the good

- Aluminosilicate ceramic fiber has two different production processes, respectively, the rejection process and the blowing process. The carpet produced by the spinning process has long fiber length, high tensile strength and wide range of use. The blanket produced by blowing process is short in length and easy to break, and the scope of application is relatively narrow.

- Q: Ceramic fiber material fire shutter door how many square?

- Now there are two kinds of rolling to use ceramic fiber: a called inorganic super fire shutter (commonly known as the double track curtain), the curtain surface is glass fiber cloth + ceramic fiber cloth + ceramic fiber blanket + aluminum foil cloth, one is WFJ (glass fiber cloth + ceramic fiber cloth + glass fiber cloth).

Send your message to us

Ceramic Fiber Bulk Insulation for Insulating Lining

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords