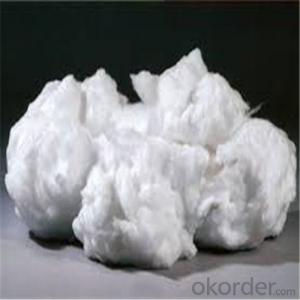

High Quality Ceramic Fiber Bulk

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic fiber bulk is made of coal gangue by melting at high temperature through resistance furnace, before being blown or spun into fiber.

As a neutral and acidic material, except reaction with the strong acid-alkali, ceramic fiber won’t be eroded by other weak alkali, weak acids, or water, oil, steam, or be infiltrated with lead, aluminum or copper, featuring excellent flexibility and elasticity.

Ceramic Fiber Bulk

Product Description

The polycrystal alumina fiber bulk is made of melted aluminum salt through chemical colloid method.

The solution is heated and inspissated into fiber under specific conditions and got polycrystal alumina fiber after the heat treatment

Ceramic fiber bulk show a high temperature stability.Low weight , heat capacity and an outstanding sound absorption is complemented by their resistance to shock and erosion.

Product Features

Excellent thermal stability and chemical stability

Keep loose ,soft and elastic under high temperature

Low thermal conductivity and heat storage

Excellent thermal shock resistance

No bond and corrosive material

Excellent sound absorption

Product Application

Filling material for expansion gap

Base material for the production of board,paper,profiled fiber

Fire strengthen material for heat insulation beton and bonding agent

Type | Standard | High Pure | High Aluminum | Zirconium |

Classification temp(°C) | 1260 | 1260 | 1360 | 1430 |

Work temp(°C) | 1050 | 1100 | 1200 | 1350 |

Color | Pure White | Pure White | Pure White | Pure White |

Fiber diameter(um)Blown | 2--3 | 2--3 | 2--3 | 2--3 |

Fiber diameter(um)Spun | 3—4.5 | 3—4.5 | 3—4.0 | 3—4.0 |

AL2O3(%) | 45--46 | 47--49 | 52--55 | 39--40 |

AL2O3+SIO2(%) | 97 | 99 | 99 | ------- |

ZrO2(%) | ------ | -------- | -------- | 15--17 |

Fe2O3(%) | <1.0 | 0.2 | 0.2 | 0.2 |

Na2O+K2O(%) | <0.5 | 0.2 | 0.2 |

- Q: What are the main differences between an ordinary furnace and a ceramic fiber furnace?

- Service life: ordinary furnace quenching, sudden heat, easy to cause blasting chamber or cracking, shorten service life, ceramic fiber furnace without blasting chamber or crack possible.There are two common practices in ceramic fiber furnaces:The first is a larger furnace, which is fixed on the furnace wall with ceramic fiber modules;The second is a small furnace, the manufacture of abrasives, direct pouring, or with punch milling machine processing ceramic fiber board.

- Q: What is the difference between the ceramic fiber cloth and the high silicon oxygen cloth?

- High temperature is similar to that of strength, service life, the price is high silica cloth. High silica fabric belongs to glass fiber.

- Q: Aluminum silicate ceramic fiber cotton smoke will cause pneumoconiosis?

- Most of the aluminosilicate ceramic fiber cotton with high quality bauxite, high purity alumina, silica, zircon sand as raw materials, by blowing or swinging method generated by fiber, cotton collector or settlement device assembled into bulk fiber, also known as cotton fiber. Therefore, according to its composition, after inhalation, will lead to pneumoconiosis.

- Q: Is the ceramic fiber cloth poisonous?

- Aluminum silicate fiber textiles can replace asbestos textiles, widely used in metallurgy, chemical industry, ceramics. Glass, refractories, shipbuilding, aerospace, automotive, machinery, electronics, building materials, light industry and other industrial sectors of the fire-resistant, heat insulation, fire prevention, friction, sealing, silencing, labor protection, high temperature filtering etc..Landlord, it seems that this material is non-toxic, rest assured that the use of good.

- Q: What is the diameter of the ceramic fiber? How to mix?

- Fiber length: fiber rejection is longer, the rejection of silk fiber is generally 150-250mm, spinneret fiber is generally 100-200mm;

- Q: Is aluminum silicate fiber poisonous?

- Then use the compressed air jet or use the wire throwing machine to turn the yarn into a fiber. After the cotton collector sets the cotton, it forms the ceramic fiber cotton. In the whole process of production, it can be found that the raw material does not contain toxic substances. Compared with asbestos, it is a substitute product of asbestos and contains no carcinogens.

- Q: What is the good heat insulation effect of glass fiber and aluminum silicate fiber, what are their respective advantages and disadvantages?

- Applicability: glass fiber (melting point 680 degrees) belongs to medium and low temperature insulation material, suitable temperature is below 700 degrees, aluminum silicate fiber belongs to high temperature insulation material, use fire temperature 1000~1790 degrees.

- Q: The difference between the ceramic fiber blanket and rock cotton blanket

- The heat capacity (heat storage capacity) of ceramic fiber lining is low: the heat capacity of ceramic fiber is only about l/10 of light heat resistant lining and light castable lining, and the heat capacity of lining material is proportional to the weight of lining. Low heat capacity means the furnace in the reciprocating operation absorb less heat and heating speed, greatly reducing the operational control of the temperature in energy consumption, especially for heating furnace and furnace, furnace shutdown has obvious energy saving effect.

- Q: Aluminum silicate needle carpet and ceramic fiber insulation performance of the good

- Aluminosilicate ceramic fiber has two different production processes, respectively, the rejection process and the blowing process. The carpet produced by the spinning process has long fiber length, high tensile strength and wide range of use. The blanket produced by blowing process is short in length and easy to break, and the scope of application is relatively narrow.

- Q: Ceramic fiber material fire shutter door how many square?

- Now there are two kinds of rolling to use ceramic fiber: a called inorganic super fire shutter (commonly known as the double track curtain), the curtain surface is glass fiber cloth + ceramic fiber cloth + ceramic fiber blanket + aluminum foil cloth, one is WFJ (glass fiber cloth + ceramic fiber cloth + glass fiber cloth).

Send your message to us

High Quality Ceramic Fiber Bulk

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords