Ceramic Fiber Bulk Paper for Inner Insulation Lining

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Ceramic fiber paper is made from ceramic fiber with mixing of binders by continuous wet modeling process. The highest temperature is 1600℃

Characteristics

Asbestos-free

Accuracy of the thickness and High flexibility

High strength and strong tensile properties

Resistance to erosion

Low thermal conductivity and resistance to thermal shock

High electrical insulation

Typical Applications

Used in household heat facilities do slice

Used in Electric appliances insulating materials

Used in High temperature insulation sealing gasket

Used in High temperature filter material

Used in automotive heat shields and silencer insulation

Used in Seal materials for furnace expansion joints

Used in Furnace, the furnace door, top seal

Used in Fire protection

Used in Instead of asbestos

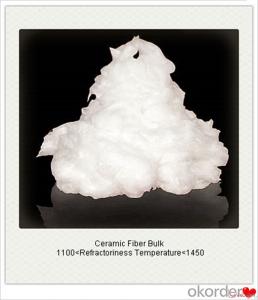

Image of Ceramic Fiber Paper

product code | WHCF-61 | HWCF-62 | WHCF-64 | WHCF-65 | WHCF-66 |

1000 | 1260 | 1430 | 1500 | 1600 | |

Classification Temp. ( ℃) | 1000 | 1260 | 1430 | 1500 | 1600 |

Density: (Kg/m3 ) | 210 | 210 | 210 | 160 | 180 |

Linear Shrinkage(%)(℃*24h) | 3.5 (850) | 3.0 (1100) | 3.2(1200) | 3.6(1400) | 3.4(1500) |

Rupture strength (MPa) | 0.50 | 0.65 | 0.70 | 0.60 | 0.60 |

Organic content (%) | 10 | 8 | 6 | 7 | 7 |

thermal conductivity Kcal/mh℃(W/mK) (ASTM C-201Average Temp. As belows) | |||||

400℃ | 0.06 | 0.07 | |||

600℃ | 0.08 | 0.09 | 0.08 | 0.08 | 0.07 |

800℃ | 0.14 | 0.13 | 0.12 | 0.12 | 0.11 |

1000℃ | 0.17 | 0.16 | 0.16 | 0.15 | |

chemical composition (Post-burnt) | |||||

Al2O3 | 42 | 46 | 35 | 40 | 70 |

SiO2 | 54 | 50 | 44 | 58.1 | 28 |

ZrO2 | 15.5 | ||||

Cr2O3 | 2.5 | ||||

Dimension (mm) | 40000×600/1000/1200×0.5,1;20000×600/1000/1200×2;10000×600/1000/1200×3,4,5,6. | ||||

Note:1. The products can process into gasket sheet, more details information please look at page12 for your reference.

2. More details information of Soluble Fiber Eco-product and relevant products please look at page4 for your reference.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisors.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

- Q: What are the main differences between an ordinary furnace and a ceramic fiber furnace?

- Service life: ordinary furnace quenching, sudden heat, easy to cause blasting chamber or cracking, shorten service life, ceramic fiber furnace without blasting chamber or crack possible.There are two common practices in ceramic fiber furnaces:The first is a larger furnace, which is fixed on the furnace wall with ceramic fiber modules;The second is a small furnace, the manufacture of abrasives, direct pouring, or with punch milling machine processing ceramic fiber board.

- Q: What is the density of ceramic fiber modules? The best insulation effect

- Ceramic fiber module density in 200-220, the first production of ceramic fiber module is generally made of ceramic fiber blown blanket, fiber blown blanket fine short, ceramic fiber module is made out of the expansion is relatively stable, but in recent years because of the cost of production, the majority of ceramic fiber module are thrown silk do relatively, the tensile force is big, according to your own combustion atmosphere of furnace temperature and heating module and intracranial, select the density and thickness of the ceramic fiber module. Just make the insulation layer, then recommend 200kg/ cubic meters. Ring fire-resistant insulation materials company has a specific index and design analysis.

- Q: What is the difference between the ceramic fiber cloth and the high silicon oxygen cloth?

- High temperature is similar to that of strength, service life, the price is high silica cloth. High silica fabric belongs to glass fiber.

- Q: Glass fiber cotton, aluminum silicate cotton, rock wool, what's the difference between these three?

- Name: Cotton aluminosilicate ceramic fiber cotton, is an almost pure inorganic fiber, formed by blowing process production process or thrown silk spray, is a kind of low thermal conductivity, low heat capacity; high strength, high tear resistance, excellent machining performance. Aluminum silicate insulation material has become the best industrial furnace lining wall insulation materials, completely replace refractory bricks.

- Q: Aluminum silicate ceramic fiber cotton smoke will cause pneumoconiosis?

- 1, general masks, gauze, masks, etc., can not be used as dust masks.2, mask must pass GB 2626-2006 standard certification.3, it is recommended to choose N100 class dust masks.4, individual suggestions according to choose different shapes masks.5, it is recommended to change the filter gauze mask. Material recommended for silicone material.Through the above way, it can effectively prevent pneumoconiosis.

- Q: Is the ceramic fiber cloth poisonous?

- Aluminum silicate fiber textiles can replace asbestos textiles, widely used in metallurgy, chemical industry, ceramics. Glass, refractories, shipbuilding, aerospace, automotive, machinery, electronics, building materials, light industry and other industrial sectors of the fire-resistant, heat insulation, fire prevention, friction, sealing, silencing, labor protection, high temperature filtering etc..Landlord, it seems that this material is non-toxic, rest assured that the use of good.

- Q: What is the diameter of the ceramic fiber? How to mix?

- Fiber diameter: rejection fiber more coarse, rejection fiber generally 3.0-5.0 - m, spinneret fiber is generally 2.0-3.0 - m;

- Q: What is the good heat insulation effect of glass fiber and aluminum silicate fiber, what are their respective advantages and disadvantages?

- Adiabatic effect: glass fiber thermal conductivity at room temperature was about 0.056, the thermal conductivity at room temperature is about 0.035, due to the lower thermal conductivity, moisturizing effect is better, so the material characteristics of aluminum silicate fiber insulation effect is good, but also with the insulation effect of fiber compression density, can not be generalized.

- Q: Aluminum silicate needle carpet and ceramic fiber insulation performance of the good

- Aluminum silicate needle carpet should be aluminum silicate needled blanket, with the continuous production, by acupuncture fiber uniformity, high tensile strength, does not contain any additives. Ceramic fiber, also known as aluminum silicate fiber, is only a different name.

- Q: Ceramic fiber material fire shutter door how many square?

- Now there are two kinds of rolling to use ceramic fiber: a called inorganic super fire shutter (commonly known as the double track curtain), the curtain surface is glass fiber cloth + ceramic fiber cloth + ceramic fiber blanket + aluminum foil cloth, one is WFJ (glass fiber cloth + ceramic fiber cloth + glass fiber cloth).

Send your message to us

Ceramic Fiber Bulk Paper for Inner Insulation Lining

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords