Ceramic Fiber Bulk for Heat Insulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Ceramic fiber bulk is made of coal gangue by melting at high temperature through

resistance furnace, before being blown or spun into fiber.

As a neutral and acidic material, except reaction with the strong acid-alkali, ceramic fiber won’t

be eroded by other weak alkali, weak acids, or water, oil, steam, or be infiltrated with lead,

aluminum or copper, featuring excellent flexibility and elasticity,also lightweight,heat insulation,

low thermal conductivity etc.

Ceramic fiber bulk application

(1)Raw material for fiber blanket, board products; Raw material for fiber textile products;

(2) Joint sealing and filling insulation for industrial kilns and fuming channel and high temperature pipes

(3) Raw material wet processed products;

(4) Fiber spraying;

(5) Raw material for coatings and castables;

(6) Insulation fillings for corner and complex space.

Specifications

Refractory ceramic bulk

Low thermal conductivity

Excellent thermal stability

Excellent sound absorption

DATA SHEET

CERAMIC FIBER BULK-STD | |

Classification Temperature(℃) | 1260 |

Working Temperature (℃) | 1050 |

Melting Point ( ) ℃ | 1600 |

Color | White |

Short Content (%) | <15< span=""> |

Chemical Composition (%) | |

Al2O3 | 45-47 |

Al2O3+ SiO2 | 98.5 |

Fe2O3 | <0.4< span=""> |

K2O+Na2O | <0.3< span=""> |

CaO + MgO | <0.2< span=""> |

Note: Technical Data are typical results from test pieces. This information, subject to change, is offered solely for your consideration. Users of our products should make their own tests to determine the suitability of each product for their particular purposes

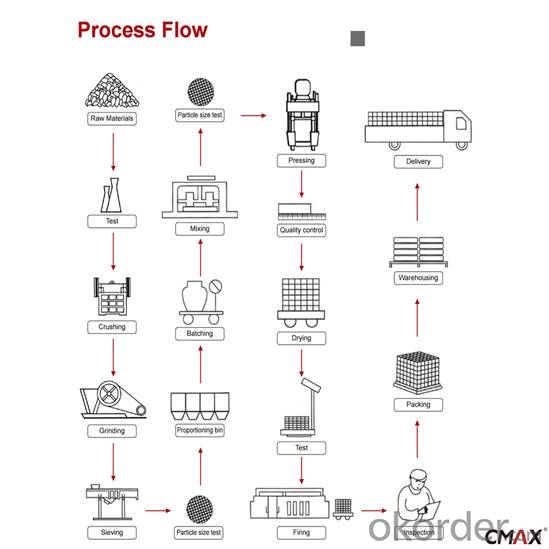

Packaging & Delivery

Packaging Details: Wrapped by plastic bag and then put into carton box designed for export.

Delivery Detail: 30 days after order

Our Services

Optimum solution and product supply of refractories for high temperature industries, such as iron steel, non-ferrous, petrochemical and building materials.

Engineering design, contract and consult for refractories, and civil architecture design.

Research, development, manufacture and sale of superhard materials.

R&D, manufacture and sale of special packing materials for export.

Inspection, supervision and arbitration of refractories.

Consultation and services in refractories information.

Training and cultivation of high-level talents in refractories profession

Company Information

CNBM (China National Building Material) Group is the largest comprehensive building materials group in China that in integrate scientific research, manufacturing and logistics into one entity. The largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields, CNBM is playing the leading role in the building industry in the country.

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

3. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc. If any question, please contact us freely.

- Q: What is the density of ceramic fiber modules? The best insulation effect

- Ceramic fiber module density in 200-220, the first production of ceramic fiber module is generally made of ceramic fiber blown blanket, fiber blown blanket fine short, ceramic fiber module is made out of the expansion is relatively stable, but in recent years because of the cost of production, the majority of ceramic fiber module are thrown silk do relatively, the tensile force is big, according to your own combustion atmosphere of furnace temperature and heating module and intracranial, select the density and thickness of the ceramic fiber module. Just make the insulation layer, then recommend 200kg/ cubic meters. Ring fire-resistant insulation materials company has a specific index and design analysis.

- Q: Should the ceramic fiber furnace be compacted?

- The simplest, the least durable method, uses ceramic fiber blankets for wrapping, which is often caused by the poor density of the ceramic fiber blanket and the lack of anchorage

- Q: Aluminum silicate ceramic fiber cotton smoke will cause pneumoconiosis?

- Because pneumoconiosis can not be cured by medical treatment, it brings great pains to the patients and the families. It is suggested that respiratory protection work be carried out.

- Q: Is the ceramic fiber cloth poisonous?

- Aluminum silicate fiber textiles can replace asbestos textiles, widely used in metallurgy, chemical industry, ceramics. Glass, refractories, shipbuilding, aerospace, automotive, machinery, electronics, building materials, light industry and other industrial sectors of the fire-resistant, heat insulation, fire prevention, friction, sealing, silencing, labor protection, high temperature filtering etc..Landlord, it seems that this material is non-toxic, rest assured that the use of good.

- Q: What is the diameter of the ceramic fiber? How to mix?

- Fiber diameter: rejection fiber more coarse, rejection fiber generally 3.0-5.0 - m, spinneret fiber is generally 2.0-3.0 - m;

- Q: Is aluminum silicate fiber poisonous?

- Hello, silicate in the stomach and stomach acid reaction, forming insoluble silicic acid. There should be no toxicity.

- Q: What is the good heat insulation effect of glass fiber and aluminum silicate fiber, what are their respective advantages and disadvantages?

- Applicability: glass fiber (melting point 680 degrees) belongs to medium and low temperature insulation material, suitable temperature is below 700 degrees, aluminum silicate fiber belongs to high temperature insulation material, use fire temperature 1000~1790 degrees.

- Q: The difference between the ceramic fiber blanket and rock cotton blanket

- Refractory ceramic fiber material is a lightweight and efficient thermal insulation material. It has the following advantages over traditional heat insulation materials:Ceramic fiber as lining, low volume density: ceramic fiber lining than light heat insulation brick lining light more than 75%, lighter than light castable lining light 90% to 95%. If using fiber lining, it can greatly reduce the steel structure load and prolong the service life of the furnace.

- Q: Aluminum silicate needle carpet and ceramic fiber insulation performance of the good

- Aluminosilicate ceramic fiber has two different production processes, respectively, the rejection process and the blowing process. The carpet produced by the spinning process has long fiber length, high tensile strength and wide range of use. The blanket produced by blowing process is short in length and easy to break, and the scope of application is relatively narrow.

- Q: Ceramic fiber material fire shutter door how many square?

- If the above two kinds of roller blinds, really true to do, the former per square meter at least 500 yuan, and the latter at least 400 yuan per square meter. Otherwise, there must be a problem.

Send your message to us

Ceramic Fiber Bulk for Heat Insulation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords