Insulating Fire Brick - CCE Fire Light Dense Mullite Insulation Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

Refractory brick is a refractory material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment and good service

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

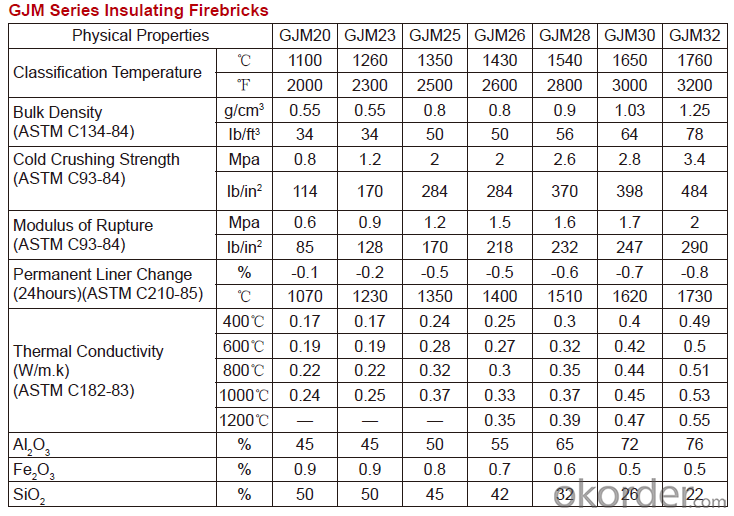

Insulating Fire Brick main feature:

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

3 large flexible crushing and sieving lines for grit production lines

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

FAQs

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Are insulating fire bricks suitable for use in heat exchangers?

- Yes, insulating fire bricks are suitable for use in heat exchangers. These bricks are designed to withstand high temperatures and provide excellent insulation, making them ideal for heat transfer processes. They are commonly used in various industries, including metallurgy, glass, and ceramic manufacturing, where heat exchangers are essential for efficient heat transfer.

- Q: Can insulating fire bricks be used as a base material for casting refractory shapes?

- Indeed, insulating fire bricks are viable for serving as a foundational material for molding refractory shapes. These bricks are engineered with the explicit purpose of enduring extreme temperatures and delivering insulation, rendering them appropriate for deployment in refractory applications. Notably, they possess a low thermal conductivity, thereby minimizing heat dissipation and maximizing energy efficiency. Furthermore, their lightweight composition facilitates convenient handling and shaping, rendering them an optimal foundational material for casting refractory shapes. Nevertheless, it is crucial to carefully scrutinize the specific requirements and characteristics of the refractory shapes being molded to ascertain that insulating fire bricks are the most suitable option for the intended application.

- Q: Can insulating fire bricks be used in the construction of hot blast stoves?

- Indeed, it is possible to utilize insulating fire bricks in the fabrication of hot blast stoves. These bricks are specifically engineered to possess a low thermal conductivity, rendering them highly efficient in diminishing heat dissipation. In order to ensure optimal functionality, hot blast stoves necessitate the maintenance of elevated temperatures, a goal that can be accomplished through the utilization of insulating fire bricks, which effectively restrict heat transfer to the stove's external surface. Furthermore, these bricks exhibit commendable insulation properties, enabling energy conservation and enhancing the overall efficiency of the stove. Moreover, it is worth noting that insulating fire bricks are resistant to thermal shock, a crucial attribute in hot blast stove applications where frequent temperature fluctuations are common.

- Q: Can insulating fire bricks be used for high-temperature insulation?

- Absolutely, high-temperature insulation can be achieved with the use of insulating fire bricks. These bricks are specifically engineered to endure and provide insulation against elevated temperatures, making them exceptionally suitable for a wide range of high-temperature applications. Constructed from lightweight refractory materials, these bricks exhibit remarkable thermal conductivity properties, effectively capturing and hindering heat transfer. They find extensive utilization in furnaces, kilns, ovens, and other heating apparatuses that necessitate insulation against extreme temperatures. Capable of withstanding temperatures as high as 3000°F (1650°C), insulating fire bricks offer a dependable solution for high-temperature insulation requirements.

- Q: Are insulating fire bricks resistant to impact or mechanical stress?

- Yes, insulating fire bricks are generally resistant to impact and mechanical stress due to their high strength and durability.

- Q: Can insulating fire bricks be used for insulation in steam pipes?

- Yes, insulating fire bricks are a suitable option for insulation in steam pipes. These bricks are specifically designed to withstand high temperatures and provide excellent thermal insulation. They have low thermal conductivity, which means they prevent the transfer of heat effectively. This property makes them ideal for insulating steam pipes, as it helps to minimize heat loss and maintain the temperature of the steam inside the pipes. Additionally, insulating fire bricks are lightweight and easy to install, making them a convenient choice for insulating steam pipes.

- Q: How do insulating fire bricks contribute to reducing heat loss?

- Insulating fire bricks contribute to reducing heat loss by providing a high level of thermal insulation. These bricks are specifically designed to have low thermal conductivity, which means they are able to trap and retain heat within a given space. This insulation property helps to prevent the transfer of heat from one side of the brick to the other, effectively reducing heat loss. By using insulating fire bricks, heat can be conserved and efficiently utilized, resulting in energy savings and improved overall thermal efficiency.

- Q: Can insulating fire bricks be used in the construction of combustion flues?

- Yes, insulating fire bricks can be used in the construction of combustion flues. Insulating fire bricks are designed to withstand high temperatures, making them ideal for use in environments where heat resistance is required. Combustion flues are exposed to extreme heat and gases generated during combustion, and insulating fire bricks can help protect the flue structure from the intense heat and prevent heat loss. Additionally, these bricks have low thermal conductivity, meaning they are effective in insulating and retaining heat within the flue. This can help improve the efficiency of the combustion process and minimize energy waste. Overall, the use of insulating fire bricks in the construction of combustion flues can enhance safety, efficiency, and longevity of the flue system.

- Q: Can insulating fire bricks be recycled or reused?

- Yes, insulating fire bricks can be recycled or reused. They can be crushed down and used as fillers in various construction materials or as a base material for roads. Additionally, they can be reclaimed and reused in various industrial processes that require heat insulation.

- Q: Are insulating fire bricks suitable for insulation in chemical reactors?

- Insulating fire bricks are often used for insulation in chemical reactors due to their excellent thermal properties and resistance to high temperatures. These bricks are made from lightweight refractory materials such as alumina, silica, and other minerals, which provide insulation against heat transfer. They have low thermal conductivity and high heat capacity, allowing them to effectively reduce heat loss and maintain stable temperatures inside the reactor. Chemical reactors often operate at high temperatures and may contain corrosive or reactive substances. Insulating fire bricks are able to withstand these harsh conditions and protect the reactor from external heat sources. They are chemically inert and resistant to corrosion, making them suitable for use with various chemicals and reactants. Additionally, insulating fire bricks have a low thermal expansion coefficient, which means they can withstand thermal cycling without cracking or deforming. This is crucial in chemical reactors where temperature changes are frequent and can cause damage to the equipment. Overall, insulating fire bricks are a popular choice for insulation in chemical reactors due to their thermal insulation properties, chemical resistance, and ability to withstand high temperatures and thermal cycling. Their use helps to improve the efficiency and safety of chemical processes by maintaining optimum operating conditions inside the reactor.

Send your message to us

Insulating Fire Brick - CCE Fire Light Dense Mullite Insulation Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords