020 Aluminum Coil for Casting to Thinner Coils - CC Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CC Aluminum Coil for Casting to Thinner Coils

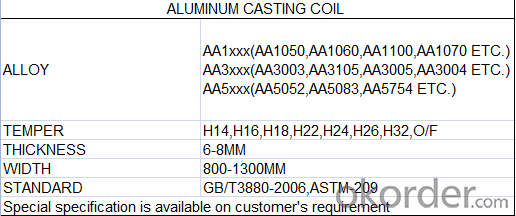

1.Structure of CC Aluminum Coil for Casting to Thinner Coils

CC Aluminum Coil for Casting to Thinner Coils is used in the factories that produce aluminum coil from 0.2mm to 6mm by thickness. Hot rolled y cold rolled son available. The thickness of CC Aluminum Coil for Casting to Thinner Coils is about 6-8mm. You can choose the alloys as your using and we will do our best to meet your requests.

2.Main Features of the CC Aluminum Coil for Casting to Thinner Coils

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Low tolerance

• Strict quality control

• Well packaged

3. CC Aluminum Coil for Casting to Thinner Coils

4. Production Process of CC Aluminum Coil for Casting to Thinner Coils

Cold Rolled

Hot rolled

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① What is the MOQ of CC Aluminum Coil for Casting to Thinner Coils

Usually the MOQ is 150 tons, but we also can make solution according to clients’ situation.

②How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

③Can you guarantee the quality of the products?

We are responsible for the quality of materials in a reasonable period of time to get a long-term cooperation with clients and we are glad to arrange and coordinate any third party inspection for you.

④What is the delivery time after purchase?

15 day with normal specification after receiving client’s deposit or correct LC

- Q: How are aluminum coils used in the production of automotive radiators?

- Due to their exceptional heat transfer properties and lightweight nature, aluminum coils are widely utilized in the production of automotive radiators. These coils are typically crafted from high-quality aluminum alloy, which offers superior thermal conductivity compared to other materials. In the manufacturing process, aluminum coils undergo initial shaping to achieve the desired configuration for the radiator's core. This can be accomplished through various methods, such as extrusion or rolling. Once shaped, the coils are meticulously stacked and bonded together to create a robust and efficient heat exchanger. The primary function of aluminum coils in automotive radiators is to facilitate the transfer of heat from the engine coolant to the surrounding air. As the hot coolant flows through the radiator's tubes, the aluminum coils efficiently absorb and disperse this heat. The coils' large surface area, combined with their excellent thermal conductivity, ensures effective heat dissipation. Additionally, the lightweight nature of aluminum makes it an ideal material for automotive radiators. By reducing the weight of vehicles, aluminum coils contribute to improved fuel efficiency and overall performance. Compared to traditional copper or brass counterparts, aluminum coils offer a lighter radiator. Furthermore, aluminum coils provide several other advantages in radiator production. They possess corrosion-resistant properties, which enhance the radiator's lifespan and durability. Aluminum coils also enable more flexible designs, allowing for the creation of radiators with intricate shapes and configurations to accommodate various vehicle models. In conclusion, aluminum coils play a critical role in the production of automotive radiators. Their exceptional heat transfer properties, lightweight nature, corrosion resistance, and design flexibility make them an optimal choice for manufacturing efficient and reliable radiators for automobiles.

- Q: I am wondering if a deodorant made with aluminum silicate is safer than one with aluminum salt.

- aluminum silicates have been used in deodorants for years. there was a time when it was thought that the Al in the deodorants was causing alzheimers but that has been shown to be wrong. if there are other dangers to the silicates, we haven't found them or they aren't that bad

- Q: I am shopping for new Rollerblades and see their newer skates have Aluminum framesand not the composite which I feel is more sturdier. What do you think of the aluminumframes? I was not impressed.

- complicated matter. research on google. this can assist!

- Q: What are the pros and cons of utilizing aluminum coils in storage applications?

- <p>Aluminum coils offer several advantages for storage, including high durability, corrosion resistance, and lightweight properties which make them easy to handle. They are also recyclable and have good thermal conductivity, which can be beneficial in temperature-controlled environments. However, there are downsides such as higher initial costs compared to some other materials and potential for denting or damage if not properly handled. Additionally, while aluminum is generally non-magnetic, it can be attracted to strong magnets, which might be a consideration in certain storage scenarios.</p>

- Q: Are there any limitations on the embossing of aluminum coils?

- There exist several limitations when it comes to embossing aluminum coils. One limitation pertains to the thickness of the aluminum coil. Thicker coils, in general, pose more difficulty during the embossing process due to the increased force required to achieve the desired pattern. Furthermore, if the thickness is already close to the upper limit for embossing, the embossing process may cause the coil to stretch or distort. Another limitation concerns the complexity of the embossing design. Elaborate or intricate patterns can prove to be more challenging to achieve on aluminum coils, particularly if they possess a lower gauge or thickness. In such cases, the embossing process may not be capable of accurately reproducing intricate designs, resulting in a less defined or distorted pattern. The size of the aluminum coil is also a potential limitation. If the coil is excessively large, achieving even embossing across the entire surface may prove difficult. This could lead to inconsistencies in the embossed pattern or the application of uneven pressure to the coil during the embossing process. Lastly, the type and quality of the aluminum can restrict the embossing capabilities. Different alloys or grades of aluminum possess varying levels of malleability and resistance to embossing. Certain alloys may be prone to cracking or deforming during the embossing process, thereby limiting the range of patterns that can be achieved. Overall, the embossing of aluminum coils is subject to limitations such as thickness, design complexity, size, and aluminum quality. It is crucial to consider these factors when embossing aluminum coils in order to attain the desired outcomes.

- Q: Why do the layers loose when taking out coil after roll of aluminum 0.14?

- After rolling, the most possible reason may be poor deoiling effect. I think, for 0.14mm aluminum coil, the lining sleeve will not be forgotten. After rolling , oil ooze from aluminum layers, and the support of aluminum coil is not enough, leading to coil collapsing. The specific manifestations are that the edges of even round aluminum layers become like water ripple, and that the aluminum coils suddenly become uneven when taking out coil.

- Q: Are aluminum pie pans and aluminum foil considered green products? They are most certainly recyclable. Thanks.?

- i would say no, because their only recycalable if they are clean. pluse the energy it takes to make them far outways the amount of times they could be re-used

- Q: How do aluminum coils contribute to energy-efficient insulation?

- The role of aluminum coils in enhancing energy-efficient insulation cannot be overstated. To begin with, aluminum is an exceptional heat conductor, allowing it to effectively transfer heat away from its source and minimize heat penetration into insulated spaces. This quality ensures a stable and comfortable indoor environment, thereby reducing the need for excessive heating or cooling. Moreover, aluminum coils find extensive application in air conditioning and refrigeration systems, where they serve as the primary heat transfer medium. By efficiently absorbing and dissipating heat, these coils expedite the cooling process, resulting in reduced energy consumption and improved overall energy efficiency. Furthermore, the lightweight nature of aluminum makes it highly convenient for handling and installation in insulation systems. Its low weight provides flexibility and ease during manufacturing and transportation, leading to cost and energy savings. In addition, aluminum coils possess remarkable corrosion resistance, guaranteeing their durability and preventing the deterioration of insulation performance over time. This longevity ensures long-term energy efficiency as the insulation system remains effective without the need for frequent maintenance or replacement. In conclusion, aluminum coils significantly contribute to energy-efficient insulation through their effective heat conduction, facilitation of rapid cooling in air conditioning systems, reduced energy consumption, lightweight and easy handling, as well as long-lasting performance due to corrosion resistance. These qualities make aluminum coils the ideal choice for enhancing energy efficiency in insulation applications.

- Q: What are the different available coil weights for aluminum coils?

- The available coil weights for aluminum coils vary depending on several factors such as the thickness, width, and alloy of the aluminum. Generally, the coil weights for aluminum coils range from a few hundred pounds to several thousand pounds. For thinner gauge aluminum coils, the coil weights typically range from 1,000 to 5,000 pounds, while for thicker gauge coils, the weights can go up to 20,000 pounds or more. The specific coil weight options also depend on the capabilities and specifications of the manufacturer or supplier. It is recommended to consult with the manufacturer or supplier to determine the exact range of available coil weights for the desired aluminum coils.

- Q: How do aluminum coils contribute to noise reduction in buildings?

- Aluminum coils contribute to noise reduction in buildings through their ability to dampen and absorb sound waves. The coil's structure and material properties help to minimize the transmission of airborne noise, preventing it from entering or exiting a building.

Send your message to us

020 Aluminum Coil for Casting to Thinner Coils - CC Aluminum Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords