Aluminum Coil Anodizers Corp - Alu Coil for Casting for Manufacture to Produce Thinner Rolls

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Alu Coil for Casting for Manufacture to Produce thinner Rolls

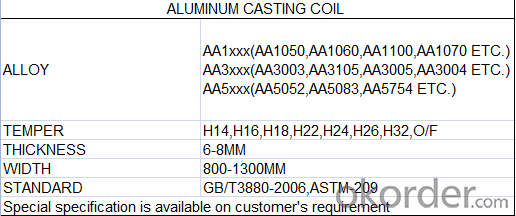

1.Structure of Alu Coil for Casting for Manufacture to Produce thinner Rolls

Alu Coil for Casting for Manufacture to Produce thinner Roll is used in the factories that produce aluminum coil from 0.2mm to 6mm by thickness. The thickness of Alu Coil for Casting for Manufacture to Produce thinner Roll is about 6-8mm. You can choose the alloys as your using and we will do our best to meet your requests.

2.Main Features of the Alu Coil for Casting for Manufacture to Produce thinner Rolls

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Low tolerance

• Strict quality control

• Well packaged

3. Alu Coil for Casting for Manufacture to Produce thinner Rolls

4. Production Process of Alu Coil for Casting for Manufacture to Produce thinner Rolls

Cold Rolled

Hot rolled

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① What is the MOQ of Alu Coil for Casting for Manufacture to Produce thinner Rolls

Usually the MOQ is 150 tons, but we also can make solution according to clients’ situation.

②How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

③Can you guarantee the quality of the products?

We are responsible for the quality of materials in a reasonable period of time to get a long-term cooperation with clients and we are glad to arrange and coordinate any third party inspection for you.

④What is the delivery time after purchase?

15 day with normal specification after receiving client’s deposit or correct LC

- Q: How are aluminum coils protected against oxidation during storage?

- Aluminum coils are protected against oxidation during storage through a variety of methods. One common method is applying a protective coating on the surface of the coils. This coating acts as a barrier, preventing oxygen from coming into contact with the aluminum and causing oxidation. The coating can be a thin layer of oil or a special protective film. Another method is storing the coils in a controlled environment with low humidity. Moisture in the air can accelerate the oxidation process, so by keeping the coils in a dry environment, the risk of oxidation is reduced. Additionally, aluminum coils can be stored in airtight packaging, such as plastic wraps or vacuum-sealed bags. This further minimizes the exposure to oxygen, preventing oxidation. It is also important to handle the coils with care during storage to avoid any damage that could potentially expose the aluminum to the air. Proper packaging and stacking techniques are crucial to ensure the coils remain protected. Overall, a combination of protective coatings, controlled environments, and proper handling techniques are employed to safeguard aluminum coils against oxidation during storage.

- Q: Can aluminum coils be used in refrigeration systems?

- Indeed, refrigeration systems can utilize aluminum coils. The rationale behind selecting aluminum as the preferred material for coil construction in refrigeration systems stems from its remarkable heat transfer capabilities and resistance to corrosion. Not only are aluminum coils lightweight and long-lasting, but they also excel in efficiently transferring heat, rendering them appropriate for a wide range of refrigeration applications, including air conditioning units, refrigerators, and freezers. Moreover, aluminum coils offer the advantage of being easier to mold and install in comparison to alternative materials, thus solidifying their position as the top choice among manufacturers.

- Q: What are the tensile strength properties of aluminum coils?

- The tensile strength properties of aluminum coils are known to be quite high. Aluminum, as a material, possesses excellent strength-to-weight ratio, which makes it suitable for various applications that require strength coupled with lightweight properties. The specific tensile strength of aluminum coils can vary depending on the alloy and temper used. Generally, aluminum coils have a tensile strength ranging from 110-310 MPa (megapascals), or approximately 16,000-45,000 psi (pounds per square inch). These values indicate the maximum amount of tensile stress that the aluminum coil can withstand before it breaks or deforms permanently. It is important to note that the tensile strength can be further enhanced by heat treatment processes such as cold rolling or annealing. Overall, aluminum coils are recognized for their impressive tensile strength properties, which contribute to their wide usage in industries like aerospace, automotive, construction, and manufacturing.

- Q: What is the typical fatigue strength of aluminum coils?

- The typical fatigue strength of aluminum coils can vary depending on various factors such as the alloy composition, heat treatment, manufacturing process, and the specific application. However, aluminum is generally known for its relatively low fatigue strength compared to other metals, such as steel. Aluminum coils typically exhibit a fatigue strength that ranges between 30% to 50% of their ultimate tensile strength (UTS). This means that the fatigue limit or endurance limit of aluminum coils is usually below half of their maximum strength. It is important to note that aluminum's fatigue strength can also be influenced by other factors, including the presence of surface defects, stress concentrations, and environmental conditions such as temperature and humidity. These factors can further reduce the fatigue strength of aluminum coils. Therefore, when designing and using aluminum coils in applications where fatigue is a concern, it is crucial to consider the specific alloy and processing conditions, as well as implementing appropriate design practices and maintenance procedures to mitigate the risk of fatigue failure.

- Q: What is the maximum temperature aluminum coils can withstand?

- The maximum temperature that aluminum coils can withstand depends on several factors, including the specific alloy of aluminum and the intended application of the coils. Generally, aluminum has a melting point of around 660 degrees Celsius (1220 degrees Fahrenheit). However, aluminum coils used in various industries such as HVAC (heating, ventilation, and air conditioning) systems and electrical appliances are typically designed to operate within a temperature range of -30 to 150 degrees Celsius (-22 to 302 degrees Fahrenheit). These temperature limits ensure that the aluminum coils maintain their structural integrity and do not experience any significant degradation or damage. It is important to consult the manufacturer's specifications or guidelines for the specific aluminum coils in question to determine their maximum temperature tolerance.

- Q: How do aluminum coils contribute to thermal insulation?

- Aluminum coils contribute to thermal insulation by acting as a barrier to prevent the transfer of heat. They are typically used in insulation systems to create a reflective surface that reflects radiant heat away from the desired area, thus reducing heat transfer and improving energy efficiency. Additionally, aluminum coils are lightweight, durable, and have good conductivity properties that help in maintaining stable temperatures and minimizing heat loss or gain.

- Q: Can aluminum coils be used in food packaging?

- Indeed, food packaging can make use of aluminum coils. Aluminum, a secure and adaptable substance, has enjoyed extensive usage in the food packaging sector for numerous years. It provides numerous advantages, including its lightweight nature, resistance to corrosion, and exceptional thermal conductivity. These qualities render it perfect for food packaging scenarios that prioritize the maintenance of food product quality, freshness, and safety. Aluminum coils can be conveniently molded into various shapes and dimensions, permitting tailored packaging solutions. Furthermore, aluminum qualifies as a sustainable material due to its 100% recyclability, further augmenting its allure for food packaging purposes.

- Q: What are the common surface treatments for aluminum coils in the marine industry?

- The common surface treatments for aluminum coils in the marine industry include anodizing, painting, and powder coating.

- Q: What are the different alloys used in aluminum coils?

- There are several different alloys commonly used in aluminum coils, each with its own unique properties and applications. Some of the most frequently used alloys include: 1. 3003: This alloy is known for its excellent formability and corrosion resistance. It is often used in applications that require moderate strength, such as automotive parts, storage tanks, and kitchen utensils. 2. 5052: This alloy is highly versatile and offers good corrosion resistance, high fatigue strength, and excellent weldability. It is commonly used in the manufacturing of aircraft fuel tanks, marine components, and architectural applications. 3. 6061: Known for its high strength and excellent machinability, 6061 is often used in structural components, such as frames and braces. It also offers good corrosion resistance and is commonly used in the aerospace and automotive industries. 4. 8011: This alloy is primarily used in the packaging industry, especially for making aluminum foil. It offers good formability, high tensile strength, and excellent resistance to moisture and chemicals. 5. 1100: This is a commercially pure aluminum alloy, known for its high electrical conductivity and good thermal conductivity. It is commonly used in electrical wiring, heat exchangers, and lighting fixtures. These are just a few examples of the alloys used in aluminum coils, and there are many other variations available to suit specific needs and applications. The choice of alloy depends on factors such as desired strength, corrosion resistance, formability, and cost considerations.

- Q: hey, my dad and i are working on painting our front door and the current piece of aluminum in front of it wont go with the new color. it doesnt look like it can be changed out so we are wondering, other than spray paint, what can you put on aluminum to make it turn permanently black. my dad mentioned gun blue, but that only works on steel. thanks

- Aluminum okorder / You could take it to someone that powder coats metals.

Send your message to us

Aluminum Coil Anodizers Corp - Alu Coil for Casting for Manufacture to Produce Thinner Rolls

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords