Monolithic Refractories Castable Block for Iron and Steel Industry Furnaces

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Castable Block for Fireplaces and Industrial Furnaces

Product Description:

Castable Block is manufactured according to international standards. The product is famous for its excellent abrasion resistance and low thermal conductivity. Further, these can be provided in different specifications as required by clients. Castables use high purity raw materials and additives as the main material, and are made with superfine powder adding technology.

Product Features:

The material has excellent structural stability and air tightness, and has high physical and chemical properties, and also excellent working ability. If should be used with the same material products.

Product Applications:

Widely used in various kiln linings, such as boilers, blast furnace hot blast stoves, heating furnaces, ceramic kilns, heat treatment furnaces, incinerators, re-circulating fluidized bed furnaces and chemical industry and construction industry furnaces.

Product Specifications:

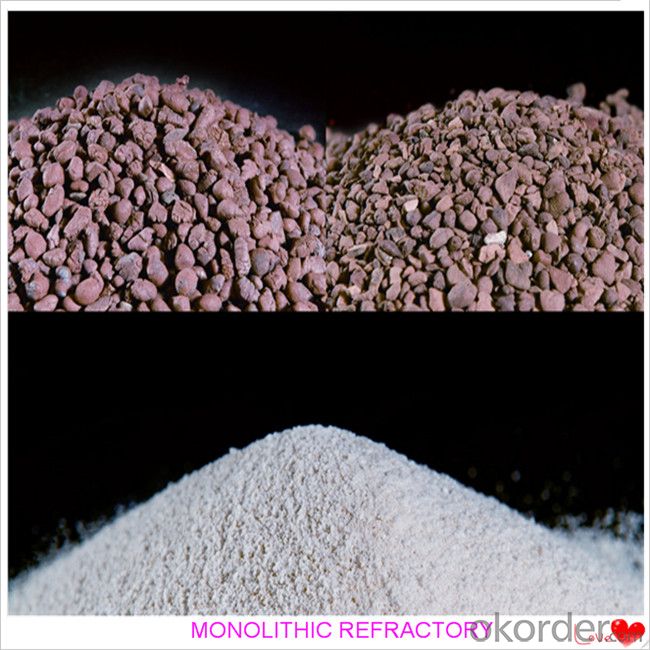

Product Images:

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

- Q: How do monolithic refractories improve the lining of converters and refining vessels?

- Monolithic refractories play a crucial role in improving the lining of converters and refining vessels in several ways. Firstly, monolithic refractories offer excellent thermal insulation properties, which helps in maintaining the desired temperature inside the converters and refining vessels. This is important because high temperatures are required for various metallurgical processes to occur effectively. Secondly, monolithic refractories have high chemical resistance, which is vital in the harsh conditions of converters and refining vessels. These vessels often come into contact with corrosive materials and aggressive slags, and the monolithic refractories prevent the lining from deteriorating or being eroded by these substances. Moreover, monolithic refractories provide superior mechanical strength and stability, ensuring that the lining remains intact even under high operational stresses. This is especially important in converters and refining vessels where there are frequent mechanical movements and thermal expansions. Additionally, monolithic refractories offer easy installation and repair. Unlike traditional bricks, which require time-consuming and complex assembling, monolithic refractories can be applied as a single mass, reducing downtime during installation or repair. This feature saves both time and cost in maintaining the lining of converters and refining vessels. Overall, the use of monolithic refractories in the lining of converters and refining vessels significantly enhances their performance and longevity. They provide excellent thermal insulation, chemical resistance, mechanical strength, and ease of installation and repair, ensuring efficient and reliable operation in the metallurgical processes.

- Q: What are the advantages of using insulating castables in the iron and steel industry?

- The advantages of using insulating castables in the iron and steel industry are numerous. Firstly, insulating castables have excellent thermal insulation properties, which help to reduce heat loss during the manufacturing process. This leads to increased energy efficiency and cost savings for the industry. Additionally, insulating castables have a low thermal conductivity, meaning they can withstand high temperatures without transferring excessive heat. This is crucial in the iron and steel industry, where temperatures can reach extremely high levels. By using insulating castables, the industry can ensure the longevity and durability of its equipment and structures. Furthermore, insulating castables have good resistance to thermal shock, meaning they can withstand rapid temperature changes without cracking or breaking. This is particularly beneficial in the iron and steel industry, where the heating and cooling processes are frequent and intense. Lastly, insulating castables have a low density, making them lightweight and easier to handle and install. This not only saves time and effort during installation but also reduces the structural load on equipment and structures. Overall, the use of insulating castables in the iron and steel industry offers advantages such as improved energy efficiency, enhanced durability, resistance to thermal shock, and ease of installation.

- Q: How are monolithic refractories repaired or replaced in iron and steel facilities?

- Monolithic refractories in iron and steel facilities are repaired or replaced through a process known as hot repair or hot gunning. This involves using specialized equipment to heat the damaged refractory material and remove it. The area is then prepared for new refractory installation, which is done by either shotcreting or gunning the new material onto the surface. This method allows for quick repairs and replacements, minimizing downtime and ensuring the efficiency and safety of the facility.

- Q: How do monolithic refractories contribute to the overall safety of iron and steel operations?

- Monolithic refractories play a crucial role in ensuring the overall safety of iron and steel operations by providing several important benefits. Firstly, monolithic refractories are known for their high thermal insulation properties, which means they can effectively withstand extreme temperatures and prevent heat loss. This is particularly important in iron and steel operations, where high temperatures are involved in various processes such as melting, casting, and heat treatment. By minimizing heat loss, monolithic refractories help in maintaining a stable temperature environment, reducing the risk of accidents and ensuring the safety of personnel. Secondly, monolithic refractories offer excellent resistance to chemical attacks. In iron and steel operations, various chemicals and gases are present that can corrode and deteriorate the lining of furnaces, ladles, and other equipment. By providing a protective barrier, monolithic refractories prevent the penetration of these corrosive substances, thus extending the lifespan of the equipment and reducing the likelihood of failures or leaks that could pose safety hazards. Additionally, monolithic refractories are known for their structural integrity and high mechanical strength. In iron and steel operations, heavy loads and stresses are common, especially during the handling and movement of molten metal and raw materials. Monolithic refractories can withstand these stresses without cracking or collapsing, ensuring the structural stability of the equipment and minimizing the risk of accidents or equipment failure. Furthermore, monolithic refractories offer excellent thermal shock resistance. During iron and steel operations, sudden temperature changes can occur due to the introduction of cold materials or liquids into hot equipment. This thermal shock can cause cracking and spalling of the refractory lining, which can compromise the safety and efficiency of the operation. Monolithic refractories, with their ability to withstand thermal shock, help in minimizing the risk of unexpected failures and maintaining the overall safety of the operation. In conclusion, monolithic refractories contribute significantly to the overall safety of iron and steel operations by providing high thermal insulation, chemical resistance, structural integrity, and thermal shock resistance. By ensuring a stable temperature environment, protecting against chemical attacks, withstanding heavy loads, and resisting thermal shock, monolithic refractories help in preventing accidents, equipment failures, and potential hazards, thus creating a safer working environment for personnel in the iron and steel industry.

- Q: How do monolithic refractories withstand high temperatures and thermal shocks?

- Monolithic refractories are able to withstand high temperatures and thermal shocks due to their unique composition and structure. They are made from a single, continuous material, which eliminates the presence of joints or seams that could weaken the refractory's integrity. This monolithic nature allows for better thermal conductivity and reduced heat transfer, enabling the material to withstand extreme temperatures without cracking or breaking. Additionally, monolithic refractories possess high thermal shock resistance, meaning they can withstand rapid temperature changes without experiencing significant damage. This resilience is achieved through the use of additives and bonding agents that enhance the material's ability to expand and contract uniformly, minimizing the risk of thermal shock-induced fractures. Overall, the cohesive design and specialized components of monolithic refractories enable them to endure high temperatures and thermal shocks more effectively than other refractory materials.

- Q: What are the factors affecting the thermal expansion of monolithic refractories?

- The factors affecting the thermal expansion of monolithic refractories are the composition of the refractory material, the temperature gradient, and the firing or curing process.

- Q: What are the typical compositions of monolithic refractories?

- The typical compositions of monolithic refractories include high alumina, fireclay, silica, magnesia, and carbon-based materials. These compositions are combined with binders, additives, and aggregates to form the monolithic refractory materials.

- Q: Can monolithic refractories be customized for specific iron and steel processing requirements?

- Indeed, monolithic refractories possess the capability to be personalized in order to satisfy the distinct demands of iron and steel processing. Renowned for their adaptability and versatility, monolithic refractories can be tailored to accommodate a wide range of applications. The formulation, tangible characteristics, and methods of installation can all be modified to cater to the specific necessities of iron and steel processing. For instance, the selection of raw materials employed in the production of monolithic refractories can be customized to endure the formidable temperatures and harsh chemical environments inherent in iron and steel processing. Diverse types of aggregates, binders, and additives can be chosen to augment the refractory's resistance against thermal shock, erosion, and corrosion. Moreover, the installation technique for monolithic refractories can be adjusted to suit the precise requirements of iron and steel processing. Whether it is gunning, casting, ramming, or spraying, the method of installation can be personalized to guarantee optimal performance and durability in the given application. Additionally, monolithic refractories can also be tailored to particular shapes and sizes to accommodate the various equipment and structures utilized in iron and steel processing. This facilitates a more precise and efficient lining of furnaces, ladles, tundishes, and other vessels, thereby enhancing overall productivity and performance in the process. In conclusion, monolithic refractories can be customized to cater to the distinct requirements of iron and steel processing by modifying their composition, tangible characteristics, installation techniques, and shape. This customization ensures that the refractories can withstand the extreme conditions encountered in these industries, resulting in improved performance, prolonged service life, and enhanced productivity.

- Q: How are monolithic refractories manufactured?

- Monolithic refractories are manufactured by combining various raw materials, such as aggregates, binders, and additives, with water to create a workable mixture. This mixture is then shaped into the desired form, either by casting, gunning, or ramming. Afterwards, the shaped refractory is dried and fired at high temperatures to achieve the desired strength and thermal properties. The manufacturing process of monolithic refractories allows for flexibility in design and installation, making them suitable for a wide range of applications.

- Q: What are the specific requirements of monolithic refractories for soaking pit applications?

- Monolithic refractories used in soaking pit applications need to possess certain specific requirements. They should be able to withstand high temperatures, typically above 1500°C, without losing their structural integrity. They should also exhibit excellent thermal shock resistance to withstand rapid temperature fluctuations during the heating and cooling cycles. Additionally, they must have good resistance to chemical erosion from molten metals and slag present in the soaking pit. Other desirable properties include low porosity, high density, and good mechanical strength to ensure long-term durability and resistance to wear and tear.

Send your message to us

Monolithic Refractories Castable Block for Iron and Steel Industry Furnaces

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords