Grade AISI431 Stainless Steel Round Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Grade AISI431 Stainless Steel Round Bar in stock

Descriptio of Grade AISI431 Steel Round Bar in Stock

(stainless steel round bar, angle bar , flat bar , channel bar , hexagon bar , square bar .)

1.grade:201,202,301,302,303,304,304L,308,309,310,310S,316,316L,321,410,420,430,etc.

2.diameter:3mm-400mm.

3.surface:bright , black , pickeled & bright .

4.length: no more than 6 m .

5.packing: according to international standards of export .

6.trade terms: FOBshanghai , CIF+import port .

7.payment terms: L/C at sight , 30% T/T in advance + copy of B/L .

8.delivery time: within 8 to 12 days since the receipt of payment .

9. MOQ is 1 ton .

Description of Grade AISI431Steel Round Bar in Stock

Standard | AISI , JIS , ER , GB , ASTM , etc. |

| Grade | 201,201,301,302,303,304,304l,308,309,310,310S,316,316L,321,410,420,etc. |

| Application | widely used in the areas as ss fasteners , chains , kitchen and sanitary wares , furniture handles , handrails , electroplating and electrolyzing pendants , foods, electron , petroleum , construction and decoration , etc. with a high strength after cold-drawn , anti-stress corrosion , good surface . |

| Chemcial composition | according to international standards of ASTM , AISI , JIS , ER , GB ,etc. |

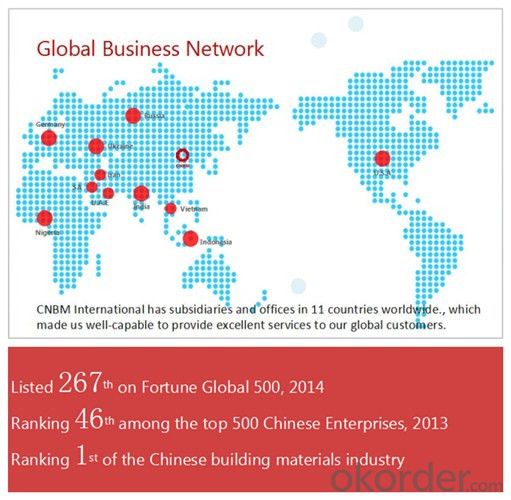

Company Information of Grade AISI431 Steel Round Bar in Stock

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of Grade AISI431 Steel Round Bar in Stock

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q:How does special steel perform in corrosive environments?

- Special steel is specifically designed to perform exceptionally well in corrosive environments. It is resistant to corrosion caused by various factors such as moisture, chemicals, and high temperatures. This type of steel typically contains higher levels of alloying elements such as chromium, nickel, and molybdenum, which enhance its corrosion resistance properties. Additionally, special steel undergoes specific heat treatments and surface finishes to further improve its resistance to corrosion. Overall, special steel exhibits excellent performance and longevity in corrosive environments, making it a preferred choice in industries such as oil and gas, chemical processing, marine, and construction.

- Q:How is precipitation-hardening steel used in aerospace applications?

- Precipitation-hardening steel is used in aerospace applications due to its excellent strength-to-weight ratio, corrosion resistance, and high temperature endurance. It is commonly used to manufacture various components like aircraft landing gear, engine parts, and structural elements. The steel's ability to be heat treated and aged to enhance its mechanical properties makes it ideal for aerospace applications, where strength, durability, and lightweight materials are crucial for safe and efficient flight operations.

- Q:Can special steel be used in the production of gearboxes?

- Yes, special steel can be used in the production of gearboxes. Special steel, such as alloy steel or heat-treated steel, is often preferred for gear manufacturing due to its high strength, durability, and resistance to wear and fatigue. These properties make special steel well-suited for transmitting power and withstanding the demands of heavy-duty applications, making it an ideal material choice for gearboxes.

- Q:What are the different types of heat treatment processes used for special steel?

- There are several different types of heat treatment processes used for special steel, including annealing, normalizing, quenching, tempering, and precipitation hardening.

- Q:What is the impact of manganese in special steel alloys?

- Manganese plays a crucial role in special steel alloys as it enhances the strength, hardness, and overall performance of the steel. It acts as a deoxidizer, removing impurities and improving the cleanliness of the metal. Additionally, manganese helps in grain refinement, reducing the risk of brittleness and improving toughness. It also aids in improving the workability and weldability of the steel, making it easier to shape and join. Overall, manganese significantly contributes to the high-quality and durability of special steel alloys.

- Q:How does special steel contribute to the performance of industrial machinery?

- Special steel contributes to the performance of industrial machinery by providing enhanced strength, durability, and resistance to corrosion and wear. It enables the manufacturing of components that can withstand high temperatures, heavy loads, and harsh operating conditions, thereby improving the overall efficiency and lifespan of the machinery. Additionally, special steel alloys offer excellent machinability and formability, allowing for precise and complex designs, ultimately enhancing the functionality and reliability of industrial machinery.

- Q:How does special steel contribute to reducing product downtime due to repairs?

- Special steel contributes to reducing product downtime due to repairs by offering superior strength, durability, and corrosion resistance. This type of steel is specifically designed to withstand harsh operating conditions and extreme temperatures, reducing the likelihood of breakdowns or failures. Its exceptional properties allow for longer periods between maintenance and repairs, ensuring that the product remains operational for extended periods. Additionally, special steel often enables faster and more efficient repairs, as it can be easily welded, machined, or replaced, minimizing the time required for downtime and maximizing productivity.

- Q:What are the different methods for tempering special steel?

- There are several methods for tempering special steel, each with its own advantages and considerations. Some of the common methods used for tempering special steel include: 1. Air Tempering: This method involves heating the steel to a specific temperature and then allowing it to cool in still air. Air tempering is often used for low alloy steels and results in a uniform hardness throughout the steel. 2. Oil Tempering: In this method, the steel is heated to a specific temperature and then quenched in oil to cool it rapidly. Oil tempering is commonly used for tool steels as it provides a good balance between hardness and toughness. 3. Water Tempering: Similar to oil tempering, water tempering involves quenching the steel in water after heating it to a specific temperature. This method provides a higher rate of cooling and results in a harder steel, but it may also lead to increased brittleness. 4. Salt Bath Tempering: In this method, the steel is immersed in a molten salt bath at a specific temperature. The salt bath provides a more controlled and uniform heat transfer, resulting in a consistent hardness throughout the steel. 5. Cryogenic Tempering: Cryogenic tempering involves cooling the steel to extremely low temperatures, often below -100°C (-148°F), using liquid nitrogen or helium. This method helps to further reduce residual stresses and increase the wear resistance of the steel. It is important to note that the specific method chosen for tempering special steel depends on various factors, including the type of steel, desired hardness, intended application, and the desired balance between hardness and toughness. It is crucial to follow proper heat treatment guidelines and consult with experts to ensure the best results for a specific steel alloy.

- Q:What are the different mining grades of special steel?

- Special steel is a term used to describe steel alloys that are specially designed for applications that require exceptional strength, durability, corrosion resistance, or other unique properties. The mining industry heavily relies on special steel for various components, tools, and equipment used in mining operations. There are several types of special steel grades specifically tailored for mining purposes, each possessing its own distinct properties and characteristics. These grades are typically classified based on their chemical composition, mechanical properties, and intended use in mining applications. Some common examples of special steel grades used in mining are: 1. High-strength Low Alloy (HSLA) Steel: HSLA steel is renowned for its remarkable strength and toughness, making it perfect for heavy-duty mining machinery and equipment. It offers exceptional weldability and corrosion resistance, which is crucial in harsh mining environments. 2. Stainless Steel: Stainless steel is extensively utilized in mining due to its superb resistance to corrosion and ability to withstand high temperatures. It is commonly employed in mining equipment such as pipes, fittings, and tanks, where resistance to corrosion and abrasion is of utmost importance. 3. Tool Steel: Tool steel is specifically engineered for cutting, drilling, and shaping tools used in mining operations. It possesses high hardness, wear resistance, and toughness, making it suitable for demanding applications like drilling bits, hammers, and cutting tools. 4. Wear-resistant Steel: Wear-resistant steel is specially designed to withstand abrasive conditions and minimize wear and tear in mining equipment. It is commonly employed in mining buckets, conveyor belts, and crushers to extend their service life and reduce maintenance. 5. Heat-resistant Steel: Heat-resistant steel is essential for mining applications involving high temperatures, such as smelting and refining processes. It retains its strength and structural integrity even at elevated temperatures, reducing the risk of equipment failure and ensuring operational efficiency. 6. Corrosion-resistant Steel: Corrosion-resistant steel finds extensive use in mining operations where exposure to corrosive substances like acids or seawater is common. It prevents rusting and degradation, thereby prolonging the lifespan of mining equipment and structures. It is important to note that the specific special steel grades used in mining may vary depending on the manufacturer and the intended use. To ensure optimal performance and suitability for mining applications, it is advisable to consult with steel manufacturers or industry experts who can provide guidance on selecting the appropriate grade for specific mining requirements.

- Q:What are the main applications of special steel in the electronics packaging?

- Special steel is widely used in electronics packaging due to its excellent properties such as high strength, corrosion resistance, and thermal conductivity. It is primarily used in the manufacturing of various components like connectors, enclosures, and heat sinks. These applications ensure the protection of delicate electronic circuits, facilitate efficient heat dissipation, and provide reliable connections, ultimately enhancing the performance and longevity of electronic devices.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Grade AISI431 Stainless Steel Round Bar Large Quantity in Stock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords