Factory Price 201 304 304L 316 316L Stainless Steel Pipe/Tube (Quality Assurance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

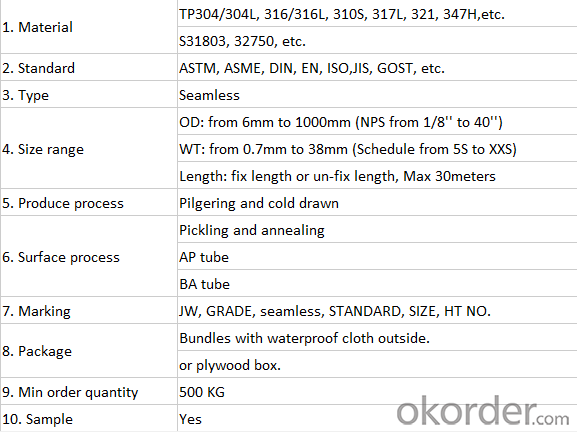

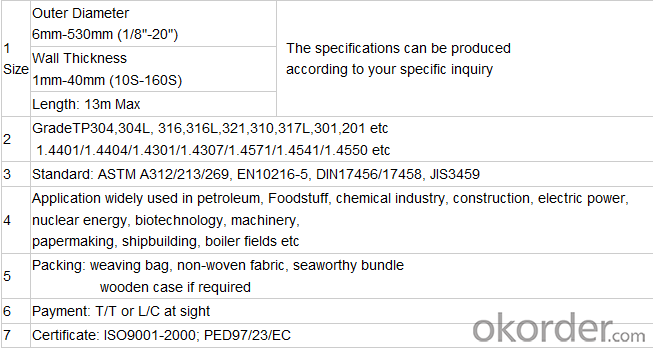

1,the description of 201 304 304L 316 316L Stainless Steel Pipe or tube

2, the 201 304 304L 316 316L Stainless Steel Pipe introduction

3,Stainless steel maintenance:

(1) Regular cleaning and maintenance

(2) Pay attention to prevent the occurrence of the phenomenon of surface scratches

(3) Use soap, weak detergent or warm water to remove surface dust, dirt

(4) In addition to the surface of the binder with alcohol or an organic solvent (ether, benzene)

(5) Use neutral detergent or ammonia solution in addition to surface oil

(6) With 10% nitric acid or abrasive detergent in addition to the surface of the embroider caused by the dirt.

4,FAQ

1. Q: What are your advantageous Products?

A: We specialized in 400 series cold rolled stainless steel coils and plates. Our main products are 430, 410S and 409L.

We also supply stainless steel strips and strips in coil as requested.

2. Q: Can you make DDQ ( Deep Drawing Quality)?

A: Yes, we can. Our material can be used for stainless steel pots, stainless steel sinks, stainless steel bowls etc. U can tell us your usage, and we will adjust the mechanical propertise to meet your requirement.

3. Q: What is the application of 400 series stainless steel?

A: 410S stainless steel and 430 stainless steel are widely used for: kitchenware, tableware, cutleries, stainless steel pots, plates & bowls, sinks, gas stove, disinfection cabinet, household appliances, construction decorations etc. 409L stainless steel is usually used for exhaust pipe.

- Q:304L stainless steel pipe can withstand 0.1MPA?

- Stainless steel pipe is a kind of hollow long strip round steel, mainly used in petroleum, chemical, medical, food, light industry, machinery, instrument and other industrial pipeline and mechanical structure parts. In addition, the bending and torsional strength of the same weight is lighter, so it is also widely used in the manufacture of mechanical parts and engineering structures. It is also used to produce all kinds of conventional weapons, guns, shells and so on.

- Q:Can stainless steel pipes be pressure tested?

- Yes, stainless steel pipes can be pressure tested. Pressure testing involves subjecting the pipes to a higher pressure than they would normally experience during normal operations to ensure their strength and integrity. Stainless steel is known for its durability and ability to withstand high-pressure conditions, making it suitable for pressure testing applications. The process involves filling the pipes with a liquid or gas and increasing the pressure to the desired level while monitoring for any leaks or failures. It is important to follow proper procedures and safety measures during pressure testing to ensure accurate results and prevent any potential hazards.

- Q:Can stainless steel pipes be used for pharmaceutical industries?

- Yes, stainless steel pipes can be used for pharmaceutical industries. Stainless steel is a common material used in the pharmaceutical industry due to its excellent corrosion resistance, durability, and hygienic properties. It is resistant to chemicals, high temperatures, and moisture, making it suitable for various applications within pharmaceutical manufacturing processes. Stainless steel pipes are often used for transporting and storing pharmaceutical products, as well as for the distribution of purified water, steam, and other fluids. Additionally, stainless steel is easy to clean and maintain, which is crucial in ensuring the cleanliness and sterility required in pharmaceutical facilities.

- Q:What is the tensile strength of stainless steel pipes?

- The tensile strength of stainless steel pipes can vary based on the specific grade and composition of the steel. However, stainless steel is renowned for its high tensile strength, making it a popular choice for various applications that demand sturdy and long-lasting pipes. On average, stainless steel pipes possess a tensile strength that falls within the range of 500 to 1500 megapascals (MPa). Thanks to this remarkable tensile strength, stainless steel pipes can endure substantial pressure and stress, rendering them suitable for utilization in industries like construction, oil and gas, chemical processing, and automotive manufacturing. It is worth noting that the precise tensile strength of stainless steel pipes can be influenced by factors such as the manufacturing process, heat treatment, and any additional alloying elements present in the steel. Consequently, referring to the specific technical specifications or standards for the particular grade of stainless steel pipes is crucial in order to ascertain their exact tensile strength.

- Q:Can stainless steel pipes be insulated with polyphthalamide?

- No, stainless steel pipes cannot be insulated with polyphthalamide.

- Q:What is the difference between seamless and SAW stainless steel pipes?

- The main difference between seamless and SAW (Submerged Arc Welding) stainless steel pipes is the method of manufacturing. Seamless pipes are formed by piercing a solid billet of steel to create a hollow tube without any welding involved. On the other hand, SAW pipes are made by continuously welding the edges of a steel plate or strip to form a pipe. This welding process can result in a visible seam along the length of the pipe. While both types of pipes offer high corrosion resistance and strength, seamless pipes are generally preferred for applications requiring higher pressure, precise dimensions, and a smoother inner surface, whereas SAW pipes are commonly used for less critical applications where cost and availability are more important factors.

- Q:What is the difference between 304F and 316F stainless steel pipes?

- The composition and characteristics of 304F and 316F stainless steel pipes are what set them apart. 304F stainless steel is categorized as an austenitic stainless steel, meaning it contains high levels of chromium and nickel. It is renowned for its exceptional corrosion resistance, weldability, and formability. Consequently, it is widely used in various industries, including food processing, chemical processing, and construction. However, 304F stainless steel is not as resistant to chloride corrosion as 316F stainless steel. On the flip side, 316F stainless steel is also classified as an austenitic stainless steel, but it has elevated levels of chromium, nickel, and molybdenum compared to 304F stainless steel. The addition of molybdenum enhances its corrosion resistance, particularly against chlorides and other aggressive chemicals. As a result, 316F stainless steel pipes are suitable for more demanding applications, such as marine environments, where exposure to saltwater and corrosive chemicals is prevalent. To sum up, the key difference between 304F and 316F stainless steel pipes lies in their corrosion resistance. While both are classified as austenitic stainless steels, 316F stainless steel offers superior resistance to chloride corrosion, making it the superior choice for applications where corrosion resistance is of utmost importance.

- Q:Can stainless steel pipes be used for solar power plants?

- Indeed, solar power plants are able to utilize stainless steel pipes. Stainless steel, being a remarkably durable and corrosion-resistant substance, proves to be fitting for outdoor and high-temperature applications like solar power plants. It retains its structural integrity and does not deteriorate even when confronted with challenging environmental conditions such as sunlight, rain, and extreme temperatures. Moreover, stainless steel pipes exhibit exceptional thermal conductivity, a crucial characteristic for effective heat transfer within solar power plants. In summary, the utilization of stainless steel pipes in solar power plants guarantees dependable and enduring performance, making it a favored option for numerous installations within the industry.

- Q:Are stainless steel pipes suitable for paper mills?

- Paper mills benefit greatly from the use of stainless steel pipes due to their suitability for the harsh conditions found in these facilities. With constant exposure to water, chemicals, and high temperatures, stainless steel pipes offer long-lasting durability. Their resistance to rust and corrosion ensures the integrity of the pipes, preventing leaks or contamination in the paper production process. Furthermore, stainless steel pipes are easy to clean and maintain, crucial for maintaining cleanliness and hygiene in paper mills. The smooth surface of these pipes prevents debris buildup, reducing the risk of blockages and improving material flow. In addition to their resistance to corrosion, stainless steel pipes are also strong and capable of withstanding high temperatures. This makes them ideal for the extreme conditions present in paper mills, where hot water, steam, and chemicals are frequently used. Overall, stainless steel pipes are an excellent choice for paper mills due to their corrosion resistance, cleanliness, durability, and high-temperature resistance. Their use contributes to efficient and reliable paper production processes.

- Q:How do stainless steel pipes perform in extreme weather conditions?

- Stainless steel pipes perform exceptionally well in extreme weather conditions due to their high resistance to corrosion, heat, and cold. They can withstand extreme temperatures, heavy rainfall, snow, and intense sunlight without deteriorating or losing their structural integrity. This makes them a reliable choice for various applications in industries such as oil and gas, construction, and marine environments.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Factory Price 201 304 304L 316 316L Stainless Steel Pipe/Tube (Quality Assurance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords