Light Duty Whole Steel Formwork for Low Building Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Light Duty Whole Steel Formwork

55 series whole steel formwork is one of the light duty steel formwork. Because of its light weight and high capacity, it is quite popular in the construction market. The thickness of 55 series steel panel is normally 2.75mm and works with different sizes.

2. Main Features of Light Duty Whole Steel Formwork

-Clean and tidy steel panel

-Light weight

-Reduced and Competitive cost

-Solid Steel panel

-Easy to dismantle

-Repeated use of 20 times

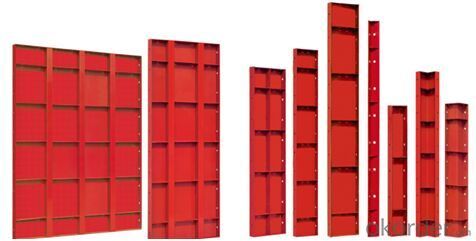

3. Light Duty Whole Steel Formwork images

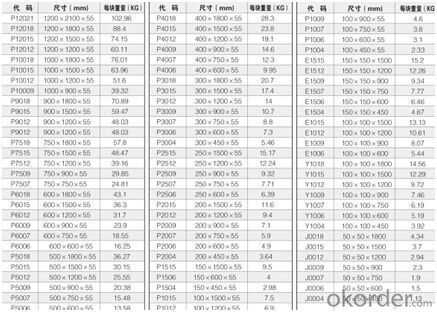

4. Light Duty Whole Steel Formwork Specifications

5. FAQ of Light Whole Steel Formwork

1) What can we do for you?

.We can ensure the quality of the Heavy Duty Whole Steel Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q:How does steel formwork handle different concrete pouring techniques?

- Steel formwork offers versatility and durability, making it an excellent option for various concrete pouring techniques. It possesses the strength and rigidity necessary to withstand the pressures exerted by different pouring methods, ensuring a stable and secure structure. One commonly used technique is gravity pouring, where concrete is poured into the formwork from above and allowed to flow downwards under its own weight. Steel formwork is highly suitable for this method as it effectively contains the concrete, preventing any leakage or spillage. The formwork's tight joints and sturdy panels ensure that the concrete remains in place and is evenly distributed throughout. Another technique is pumping, which involves using specialized equipment to pump concrete into the formwork. Steel formwork can handle this technique effectively, as it can withstand the force and pressure exerted during the pumping process. Its robust construction and reinforced edges provide the necessary support to contain the concrete and prevent any deformation or leakage. Steel formwork is also compatible with slip-forming, a technique that involves continuously pouring concrete into a moving formwork system. This method requires a formwork system that can be easily adjusted and adapted to changing shapes and heights. Steel formwork's modular design allows for quick and efficient adjustments, making it suitable for slip-forming applications. Additionally, its strength and stability ensure that the formwork remains intact during the continuous pouring process. In conclusion, steel formwork is a reliable choice for handling different concrete pouring techniques. Its strength, rigidity, and adaptability make it capable of withstanding the pressures and forces exerted by gravity pouring, pumping, and slip-forming methods. With steel formwork, builders and contractors can confidently execute various concrete pouring techniques, resulting in high-quality and structurally sound construction projects.

- Q:Can steel formwork be used for both regular and irregular concrete shapes?

- Steel formwork is capable of being utilized for both regular and irregular concrete shapes. Its versatility and strength are well-known attributes, rendering it suitable for managing diverse concrete shapes and sizes. By means of techniques like cutting, bending, or welding, steel formwork can be effortlessly tailored and adjusted to accommodate irregular shapes. The adaptability of steel formwork permits its usage in a vast array of construction undertakings, including those entailing irregular concrete shapes. Nevertheless, it is crucial to exercise caution when designing and fabricating the steel formwork, guaranteeing adequate support and stability for the concrete during the pouring and curing stages.

- Q:Can steel formwork be used for both interior and exterior concrete elements?

- Yes, steel formwork can be used for both interior and exterior concrete elements. Steel formwork is highly versatile and can be used in various construction applications. It is durable, strong, and capable of withstanding the pressure exerted by the wet concrete. Additionally, steel formwork offers excellent dimensional accuracy and can create smooth and uniform concrete surfaces. Whether it is for interior slabs, walls, or exterior foundations, columns, or beams, steel formwork is a reliable choice that can be used for both interior and exterior concrete elements.

- Q:How does steel formwork affect the overall energy efficiency of a building?

- Steel formwork can significantly affect the overall energy efficiency of a building in several ways. Firstly, steel formwork provides a robust and durable structure that can withstand high pressures, ensuring a tight and well-insulated building envelope. This prevents air leakage, reducing heat loss or gain through walls and floors, thereby improving energy efficiency. Secondly, steel formwork allows for precise construction, resulting in tighter joints and fewer gaps, which minimizes thermal bridging. Thermal bridging occurs when heat transfers through materials with high thermal conductivity, leading to energy loss. By reducing thermal bridging, steel formwork enhances insulation and reduces energy consumption. Additionally, steel formwork enables the integration of insulation materials within the construction process. Insulation can be added between the steel panels, further enhancing the energy efficiency of the building by minimizing heat transfer through the walls and floors. Furthermore, steel formwork systems often allow for the reuse of materials, reducing waste and minimizing the environmental impact of construction. This sustainable approach aligns with energy-efficient practices, as it reduces the need for new resources and lowers the embodied energy of the building. Overall, steel formwork positively impacts the energy efficiency of a building by providing a sturdy structure, minimizing thermal bridging, facilitating insulation integration, and promoting sustainable construction practices.

- Q:What are the common design considerations for steel formwork systems?

- Some common design considerations for steel formwork systems include the load capacity of the system, the stability and rigidity of the forms, the ease of assembly and disassembly, the ability to accommodate various concrete shapes and sizes, the durability and longevity of the materials, and the compatibility with other construction methods or systems. Additionally, factors such as cost, availability, and environmental impact may also be taken into account when choosing a steel formwork system.

- Q:Can steel formwork be used for infrastructure construction projects?

- Indeed, infrastructure construction projects can make effective use of steel formwork. This option, known for its versatility and durability, proves ideal for a range of infrastructure types including bridges, tunnels, dams, and buildings. Given its strength and rigidity, it can withstand the heavy loads and high pressures commonly associated with such projects. Moreover, its easy dismantling and reusability factor into its cost-effectiveness and sustainability. As an added advantage, steel formwork offers flexibility for customization, enabling precise and accurate construction tailored to specific project requirements. Ultimately, steel formwork stands as a dependable and efficient solution for infrastructure construction projects.

- Q:Can steel formwork be used in bridge construction?

- Yes, steel formwork can be used in bridge construction. Steel formwork is a durable and versatile option that can withstand the heavy loads and harsh environmental conditions associated with bridge construction. It offers the required strength and stability to support the concrete during the construction process, ensuring the bridge's structural integrity. Additionally, steel formwork can be easily assembled, disassembled, and reused, making it a cost-effective choice for bridge construction projects.

- Q:What are the different types of formwork corners used in steel formwork systems?

- There are typically three types of formwork corners used in steel formwork systems: external corners, internal corners, and chamfer corners. External corners are used to create sharp outside corners in the concrete structure. Internal corners are used to create sharp inside corners in the concrete structure. Chamfer corners are used to create beveled edges or rounded corners in the concrete structure. These different types of corners allow for flexibility in the design of the concrete structure and ensure a smooth and precise finish.

- Q:What are the different types of joints used with steel formwork?

- The different types of joints used with steel formwork include bolted joints, welded joints, and interlocking joints.

- Q:How does steel formwork perform in fire-resistant structures?

- Fire-resistant structures benefit greatly from the exceptional performance of steel formwork. Steel possesses inherent properties, including a high melting point and strength, which make it an ideal material for withstanding high temperatures and maintaining structural integrity in the event of a fire. To begin with, steel formwork exhibits non-combustible characteristics, meaning it does not contribute to the spread or intensity of a fire. Unlike certain construction materials, it does not burn or release harmful gases when exposed to flames. This quality aids in preventing the rapid propagation of fire within the structure, affording valuable time for evacuation and fire suppression efforts. Furthermore, steel possesses a high melting point in comparison to other commonly used formwork materials such as wood or plastic. This attribute enables steel formwork to retain its structural integrity even when subjected to intense heat. It can endure temperatures well above 1000°C (1832°F) without significant deformation or collapse, ensuring the stability of the structure and minimizing the risk of sudden structural failure during a fire. Moreover, steel formwork exhibits excellent load-bearing capabilities, even under high temperatures. This characteristic is crucial in fire-resistant structures as it allows the building to maintain its structural capacity when exposed to fire. The ability of steel formwork to bear the weight of the structure, even when compromised by fire, helps prevent structural collapse and ensures the safety of occupants and emergency personnel. Additionally, steel formwork is known for its durability and longevity, which are essential qualities in fire-resistant structures. It can withstand the effects of fire, such as thermal expansion and contraction, without sustaining significant damage. This durability ensures that the formwork can be reused or remain in place for future fire events, providing ongoing fire protection for the structure. In conclusion, steel formwork demonstrates exceptional performance in fire-resistant structures. Its non-combustible nature, high melting point, load-bearing capabilities, and durability make it a reliable choice for maintaining the structural integrity and safety of the building in the event of a fire.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Light Duty Whole Steel Formwork for Low Building Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords