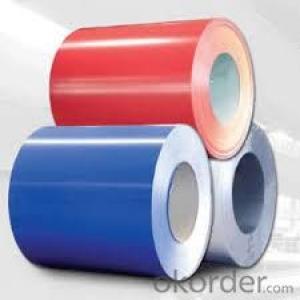

Prepainted Galvanized Rolled steel DX51D in CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

prepainted galvanized steel usually refers to have substrateprocessed with surface processed and coated then(roller coated )or bonded organic thin film and baked, and it is able to be processed tofinal prodevtion .

specification

yield strength | (mpa) 280-320 |

tensile strength | (mpa) 340-390 |

elongation | 20%-30% |

reverse impact | 9j |

t-bending | ≥2t |

pencil hardness | ≥2h |

duration of salt spray test | 500 h |

bending at 180 degree | no crack, purling and fraction |

Applications of Prepainted Galvanized Steel

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing, insulation panel, corrugate sheet, facade wall, shutters, T-bar and home appliance.

Packaging & Delivery of Prepainted Galvanized Steel

The packing of coils consists of anti-damp paper, PVC film, hardboard paper, steel box, strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye to the side) or wooden pallets(eye to the sky).

image

- Q:describe the benifits and disadvantages of the using steel as a material for fasteners

- Relatively cheap, strong, and non-toxic. For Carbon Steel alloys rust and corrosion are problems. For stainless alloys, cost becomes the problem [and corrosion is not eliminated]

- Q:What products can we make with steel (eg Steel strip, rod, bar, rail, tube) How are these made? What can we make from these steel products?Can you please make the answers as detailed as possible you can because i really want to know this really well. Thank you.

- Your okorder (they make steel deck and steel joists) There are thousands of other items routinely produced from steel, including rebar, and all the metal in cars, airplanes, and about a million other things.

- Q:How are steel coils used in the manufacturing of signage?

- Steel coils are used in the manufacturing of signage as they provide a strong and durable base for creating various types of signs. These coils are typically cut, shaped, and welded to form the desired sign structure. The steel material ensures that the signage can withstand outdoor conditions, including extreme weather, while maintaining its structural integrity. Additionally, steel coils can be easily painted or coated to enhance the visual appeal of the signage and protect it from corrosion.

- Q:What are the common methods of packaging steel coils for international shipping?

- Various techniques are employed to package steel coils for international shipment in order to guarantee their safety and security during transit. One approach involves the utilization of wooden crates. Steel coils are positioned on wooden pallets and fastened with steel bands or straps. Next, wooden boards or plywood are placed over the coils and firmly attached with nails or screws to create a robust crate. This method ensures exceptional protection against damage and guarantees that the coils remain fixed in place during transportation. Another option is to employ steel frames or skids. Steel coils are positioned on specially designed steel skids or frames that can support the weight and shape of the coils. These coils are then secured to the skids or frames using steel bands or straps. This method offers a high level of stability and protection, making it particularly suitable for larger or heavier coils. In addition to wooden crates and steel frames, steel coils can also be packaged using steel containers or shipping containers. These containers are specifically designed to transport heavy or bulky items and provide a secure and protective environment for the coils. The coils are loaded into the container and secured with steel bands or straps to prevent movement during transit. Regardless of the chosen packaging method, it is crucial to ensure that the steel coils are adequately shielded from moisture, corrosion, and other potential hazards. This may involve the use of moisture-resistant materials such as plastic or wax paper, as well as the application of protective coatings or wraps. In summary, the common methods of packaging steel coils for international shipping include wooden crates, steel frames or skids, and steel containers. The selection of these methods depends on factors such as the size, weight, and specific requirements of the coils, with the ultimate goal of providing maximum protection and security during transit.

- Q:How are steel coils used in the manufacturing of pipelines?

- Steel coils are used in the manufacturing of pipelines by being formed into large cylindrical shapes that serve as the main body of the pipelines. These coils are unrolled and then welded together to create a continuous pipeline, providing strength and durability to transport fluids or gases over long distances.

- Q:How are steel coils used in the production of metal buildings?

- Steel coils are an essential component in the production of metal buildings as they are used to create the structural framework and outer cladding. These coils are unrolled and cut into sheets, which are then shaped and formed into various building components such as beams, columns, and panels. The strength and durability of steel make it an ideal material for constructing metal buildings, ensuring they are capable of withstanding harsh weather conditions and providing long-lasting structures.

- Q:i recently got an industrial piercing and instead of getting pierced with a metal bar i have a PTFE bar .. i eventually want to put in a metal bar but what kind do i get? whats the difference between a surgical steel and titanium bar?thanks

- Titanium Industrial Bar

- Q:is stainless steel a good steel for sensitive skin? or does it have to be surgical or sterling silver?

- idk about sensitive skin but i have stainless steal in i think right now. im sure any are good for a healed belly piercing, if it hasnt been 3 monthes yet then id stick with a surgical

- Q:How is steel sustainable as a building material?How is wood sustainable as a building material?

- The choice is yours to make so just click on the proper button for the specific project and then they are right there for you to pick one. The diagrams and instructions will be right there in the computer for you to access at any time or if you prefer you can print them out.

- Q:What we have to keep in mind before buying a steel building?

- Here is a web search of the term steel building specification. It should give you some ideas and sources.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prepainted Galvanized Rolled steel DX51D in CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords