Equal Steel Angle S235JR Hot Rolled Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | In bundles and load in container, if large quantity, ship by bulk vessel. Also can be done according to customer's request |

| Delivery Detail: | Within 30 days after receipt of L/C or deposit by T/T |

Specifications

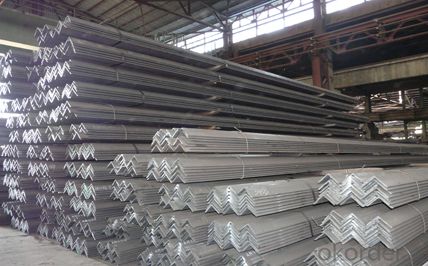

S235jr hot rolled equal steel angle

1.Grade:A36,Q235,SS400

2.Surface:galvanized,black,painted

3.Type: equal & unequal

1.Product Description

Products | S235jr hot rolled equal steel angle |

Grade | Q235,SS400B,A36,S255JR.ect |

Specification | 20*20--200*200mm. |

Length | 6m, 12m |

Technique | Hot rolled |

Application | Widely used in various building structure and engineering structure, such as the beam, bridges, transmission tower, lifting transportation machinery, ship, industrial furnace, reaction tower, container frame and warehouse.etc |

Payment | 100% irrevocable L/C at sight 30% T/T prepaid and the balance against the copy of B/L |

Reference sizes,

Size | Weight | Size | Weight | Size | Weight |

(mm) | (kg/m) | (mm) | (kg/m) | (mm) | (kg/m) |

25*3 | 1.124 | 70*6 | 6.406 | 100*16 | 23.257 |

25*4 | 1.459 | 70*7 | 7.398 | 110*8 | 13.532 |

30*3 | 1.373 | 70*8 | 8.373 | 110*10 | 16.69 |

30*4 | 1.786 | 75*5 | 5.818 | 110*12 | 19.782 |

40*3 | 1.852 | 75*6 | 6.905 | 110*14 | 22.809 |

40*4 | 2.422 | 75*7 | 7.976 | 125*8 | 15.504 |

40*5 | 2.967 | 75*8 | 9.03 | 125*10 | 19.133 |

50*3 | 2.332 | 75*10 | 11.089 | 125*12 | 22.696 |

50*4 | 3.059 | 80*6 | 7.736 | 125*14 | 26.193 |

50*5 | 3.77 | 80*8 | 9.658 | 140*10 | 21.488 |

50*6 | 4.465 | 80*10 | 11.874 | 140*12 | 25.522 |

60*5 | 4.57 | 90*8 | 10.946 | 140*14 | 29.49 |

60*6 | 5.42 | 90*10 | 13.476 | 160*12 | 29.391 |

63*4 | 3.907 | 90*12 | 15.94 | 160*14 | 33.987 |

63*5 | 4.822 | 100*8 | 12.276 | 160*16 | 38.518 |

63*6 | 5.721 | 100*10 | 15.12 | 160*18 | 48.63 |

63*8 | 7.469 | 100*12 | 17.898 | 180*18 | 48.634 |

70*5 | 5.397 | 100*14 | 20.611 | 200*24 | 71.168 |

2.Packaging & Shipping:

In bundles, load into container, if large quantity, ship by bulk vessel.

3. Relevant product pictures:

- Q:Can steel angles be used for equipment racks?

- Yes, steel angles can be used for equipment racks. Steel angles provide structural support and stability, making them suitable for holding heavy equipment and ensuring durability.

- Q:Can steel angles be used for stair stringers?

- Yes, steel angles can be used for stair stringers. Steel angles provide strong support and stability, making them a suitable choice for constructing stair stringers.

- Q:Are steel angles suitable for outdoor staircases?

- Yes, steel angles are suitable for outdoor staircases. Steel angles have high strength and durability, making them ideal for withstanding outdoor elements such as weather conditions and heavy foot traffic. Additionally, steel angles can be coated or painted to enhance their resistance to corrosion, further increasing their suitability for outdoor staircases.

- Q:Can steel angles be used as reinforcement in concrete slabs?

- Concrete slabs can indeed benefit from the use of steel angles for reinforcement. These L-shaped structural steel components, commonly utilized in construction due to their durability and strength, can significantly enhance the load-bearing capacity of a concrete slab. Furthermore, they help prevent any potential cracks or structural failure. Specifically, steel angles provide added support and strength to the concrete, especially in areas where heavy loads or concentrated forces are anticipated. By incorporating steel angles as reinforcement, the concrete slab becomes more resistant to bending, tension, and shearing forces, resulting in a structurally sound slab that can withstand higher loads. It is crucial to ensure the proper design and placement of steel angles, following the guidelines and specifications provided by structural engineers, to guarantee the optimal reinforcement and performance of the concrete slab.

- Q:How do steel angles compare to wooden beams?

- Steel angles are often preferred over wooden beams due to their superior strength and durability. Steel angles have a higher load-bearing capacity, making them suitable for supporting heavier structures. They are also fire-resistant and less susceptible to warping, rotting, or termite infestation, which are common issues with wooden beams. Additionally, steel angles are more versatile as they can be easily customized and shaped to fit specific construction requirements.

- Q:How can steel angles be protected against corrosion?

- Steel angles can be protected against corrosion through various methods. One common method is the application of protective coatings. These coatings act as a barrier between the steel angles and corrosive elements, preventing direct contact and inhibiting corrosion. Coatings such as paint, epoxy, or zinc-based materials can be used to provide this protection. Another effective method is galvanization. This process involves coating the steel angles with a layer of zinc, which acts as a sacrificial anode. When corrosion occurs, the zinc layer will corrode first, protecting the steel underneath. This is particularly effective in harsh environments, such as marine or industrial settings. Regular maintenance and inspection are essential in preventing corrosion. Any damage or deterioration to the protective coating should be promptly repaired to ensure continued protection. Furthermore, keeping the steel angles clean and free from debris or moisture buildup can also help prevent corrosion. In some cases, cathodic protection may be employed. This involves connecting the steel angles to a sacrificial anode, typically made of a more reactive metal, such as aluminum or magnesium. The anode will corrode instead of the steel angles, providing protection against corrosion. Lastly, proper design and installation of steel angles can also contribute to their corrosion resistance. Ensuring adequate drainage and ventilation, using materials compatible with the environment, and minimizing exposure to corrosive elements can all help in protecting steel angles against corrosion.

- Q:Can steel angles be used in the construction of shopping malls?

- Yes, steel angles can be used in the construction of shopping malls. Steel angles are commonly used in structural applications, including the construction of commercial buildings like shopping malls. They provide strength, stability, and support, making them a suitable choice for various structural elements such as frames, columns, and beams in shopping mall construction.

- Q:How are steel angles protected against fire damage?

- Steel angles are commonly protected against fire damage through the application of fire-resistant coatings or the use of fireproofing materials. These protective measures aim to delay or prevent the steel from reaching its critical temperature, at which it may lose its structural integrity. One common method of protecting steel angles is the application of intumescent coatings. These coatings expand when exposed to high temperatures, forming a protective char layer that insulates the steel and slows down heat transfer. This process effectively delays the rise in temperature of the steel, allowing for longer fire resistance. Another approach is the use of fireproofing materials, such as concrete or gypsum-based sprays or boards. These materials create a barrier between the steel angles and the fire, providing insulation and preventing the heat from reaching the steel. Fireproofing materials are often used in buildings where the fire resistance requirements are higher, such as high-rise structures or industrial facilities. In some cases, steel angles can also be protected by encasing them in fire-rated enclosures. This involves enclosing the steel angles within fire-rated walls, floors, or ceilings made of materials with high fire resistance. These enclosures effectively isolate the steel from potential sources of fire and provide an additional layer of protection. It is important to note that the specific fire protection measures for steel angles may vary depending on the building codes, fire safety regulations, and the intended use of the structure. Consulting with fire protection engineers and following the appropriate guidelines can ensure that the steel angles are adequately protected against fire damage.

- Q:Can steel angles be used for pipe support systems?

- Indeed, pipe support systems can indeed utilize steel angles. In construction and engineering ventures, steel angles are frequently employed due to their exceptional durability, stability, and adaptability. When employed as pipe supports, steel angles furnish a robust and dependable framework for securely holding pipes in position. They can effortlessly be joined through welding or bolting to other structural elements, rendering them suitable for a variety of pipe support applications. Furthermore, steel angles can be fabricated and tailored to satisfy specific requirements, encompassing diverse pipe sizes and load-bearing capacities. In summary, owing to their resilience and capacity to withstand substantial loads, steel angles remain a favored option for pipe support systems.

- Q:Can steel angles be used for support columns in building construction?

- Steel angles can indeed be utilized as support columns in building construction. Their strength, durability, and versatility render them frequently employed in construction. When employed as columns, they offer exceptional support and stability, particularly in structures of small to medium size. Furthermore, steel angles can be easily fabricated and tailored to satisfy precise design criteria. They also boast resistance against fire, corrosion, and pests, signifying their dependability as support columns in building construction.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Equal Steel Angle S235JR Hot Rolled Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords