E-glass Fiberglass Cloth

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Fiberglass Cloth Description:

1.The fabric of fiberglass cloth is woven by fiber glass yarn, which is treated with silane coupling agent, the kind of weave is plain.

2.It is base material of high strength,low extensibility,coating with resin

easily and surface flat and so on.

Main Features of the Fiberglass Cloth:

It has good characteristics of high tensile strength, stable tension, and no defect appearance. The fiberglass fabric can be widely applied in different industrial application such as: PTFE, silicon, PVA, PVC, PU and acrylic coating, thermal, insulation and others application.

Fiberglass Cloth Images:

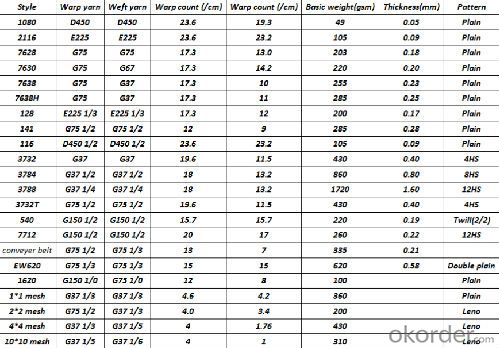

Fiberglass Cloth Specification:

FAQ of Fiberglass Cloth:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q:Is fiberglass fabric resistant to moisture in marine environments?

- Yes, fiberglass fabric is highly resistant to moisture in marine environments. It is a popular choice for marine applications due to its excellent water repellent properties. The fiberglass fabric is made from fine strands of glass fibers that are woven together, creating a strong and durable material. These fibers do not absorb water, ensuring that the fabric remains resistant to moisture even when exposed to harsh marine conditions. This resistance to moisture makes fiberglass fabric ideal for use in marine applications such as boat covers, sails, and other marine equipment where protection from water is essential. Additionally, fiberglass fabric is also resistant to the growth of mold and mildew, which further enhances its suitability for marine environments.

- Q:Can fiberglass fabric be used for reinforcement in water purification tanks?

- Yes, fiberglass fabric can be used for reinforcement in water purification tanks. It is a commonly used material due to its high strength, corrosion resistance, and durability, making it suitable for applications involving water and chemicals.

- Q:Is fiberglass fabric resistant to chemicals used in oil and gas industry?

- Yes, fiberglass fabric is generally resistant to the chemicals used in the oil and gas industry. Fiberglass is known for its excellent chemical resistance, making it suitable for various industrial applications, including oil and gas. It can withstand exposure to a wide range of chemicals, including acids, alkalis, solvents, and hydrocarbons commonly found in the oil and gas industry. This resistance is due to the inert nature of the fiberglass material, which does not react or degrade when exposed to these chemicals. Additionally, the fabric's non-porous structure prevents the absorption of chemicals, further enhancing its resistance. Overall, fiberglass fabric is an ideal choice for applications requiring chemical resistance in the oil and gas industry. However, it is always recommended to consult with manufacturers or suppliers to ensure the specific type of fiberglass fabric being used is suitable for the intended chemical environment.

- Q:Is fiberglass fabric resistant to salt spray in coastal areas?

- Indeed, in coastal areas, fiberglass fabric demonstrates resistance to salt spray. Renowned for its corrosion resistance and durability, fiberglass proves to be an exceptional option for marine-related purposes. Over time, salt spray, comprising corrosive salt particles, can inflict harm upon numerous materials. Nevertheless, fiberglass fabric is specifically engineered to endure the unforgiving conditions prevalent in coastal regions, including exposure to salt spray. It neither corrodes nor deteriorates when subjected to saltwater, rendering it an optimal selection for diverse marine applications like boat covers, sails, and awnings.

- Q:How does fiberglass fabric perform in fire resistance?

- Fiberglass fabric is known for its excellent fire-resistant properties. It is made from woven glass fibers, which are inherently non-combustible. When exposed to flames or high temperatures, fiberglass fabric does not burn or produce any smoke or toxic gases. In addition to its non-combustible nature, fiberglass fabric also has a high melting point, typically around 1,200 degrees Celsius (2,192 degrees Fahrenheit). This means that it can withstand extreme heat without melting or disintegrating, making it highly effective in fire-resistant applications. Moreover, fiberglass fabric has low thermal conductivity, which means it does not transfer heat easily. This property helps to limit the spread of fire and prevents it from reaching adjacent areas, providing additional protection. Furthermore, fiberglass fabric is often treated with special coatings or finishes to enhance its fire-resistant properties. These treatments can further improve its resistance to flames, heat, and the spread of fire. Due to these exceptional fire-resistant characteristics, fiberglass fabric is widely used in various applications where fire protection is crucial. It is commonly found in industries such as aerospace, automotive, construction, and firefighting, as well as in protective clothing and equipment. However, it is important to note that while fiberglass fabric is highly fire-resistant, its effectiveness may be affected by factors such as the thickness, quality, and specific composition of the fabric. Therefore, it is always recommended to carefully select and verify the fire-resistant properties of fiberglass fabric based on the specific requirements and standards of the intended application.

- Q:Can fiberglass fabric be used for heat-resistant aprons?

- Yes, fiberglass fabric can be used for heat-resistant aprons.

- Q:Hello, could you tell me how to do the surface treatment under the glass fiber cloth? Thank you

- Temperature resistant glass fiber cloth, with the characteristic of soft heat, compared with asbestos cloth, it has no dust, no harm to human body and other advantages, is the ideal substitute of asbestos, fire resistance, heat resistance, energy saving products is a kind of economical and practical.

- Q:Are there any limitations or drawbacks to using fiberglass fabrics?

- Yes, there are certain limitations and drawbacks to using fiberglass fabrics. Firstly, fiberglass fabrics can be relatively expensive compared to other fabric options. Additionally, working with fiberglass fabrics requires specialized equipment and expertise, making it more challenging for DIY or inexperienced users. Furthermore, fiberglass fabrics can be brittle and prone to cracking or breaking under excessive stress or impact. Finally, fiberglass fabrics may have limited flexibility, making them less suitable for applications that require a high degree of flexibility or stretchability.

- Q:What are the different weights available for fiberglass fabric?

- Various weights of fiberglass fabric are available, typically measured in ounces per square yard (oz/yd²) or grams per square meter (g/m²). The weight of fiberglass fabric corresponds to its density or thickness, which can vary depending on the intended use and desired strength. There are several weight options commonly available for fiberglass fabric: - Lightweight option: 3 oz/yd² (102 g/m²). This option is suitable for applications where flexibility and ease of use are crucial, such as lightweight composite parts, surfboards, or small craft repairs. - Medium weight option: 5 oz/yd² (170 g/m²). This fabric provides a balance between flexibility and strength, making it suitable for boat building, automotive parts, and general fiberglass repairs. - Heavy weight option: 8 oz/yd² (272 g/m²). This fabric offers increased strength and durability, making it commonly used in applications that require higher impact resistance, such as the construction of industrial tanks, pipes, or structural reinforcements. - Heavyweight options: 10 oz/yd² (340 g/m²) and above. These options provide maximum strength and rigidity, making them ideal for demanding applications like aerospace, wind energy, or heavy-duty industrial equipment. When selecting the weight of fiberglass fabric, it is crucial to consider the specific requirements of your project. Factors such as the desired level of strength, flexibility, and the type of resin or adhesive being used should be taken into account to ensure that the fabric meets the necessary specifications.

- Q:Can fiberglass fabric be used in chemical-resistant applications?

- Yes, fiberglass fabric can be used in chemical-resistant applications. Fiberglass fabric is known for its excellent resistance to a wide range of chemicals, making it a suitable choice for applications that involve exposure to various corrosive substances. Fiberglass fabric is inherently resistant to most acids, bases, solvents, and other chemicals, making it a preferred material in industries such as chemical processing, petrochemicals, oil and gas, and wastewater treatment. Additionally, fiberglass fabric can withstand high temperatures, making it even more suitable for chemical-resistant applications where heat is involved. Overall, fiberglass fabric's exceptional chemical resistance properties make it a reliable and durable choice for various chemical-resistant applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

E-glass Fiberglass Cloth

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords