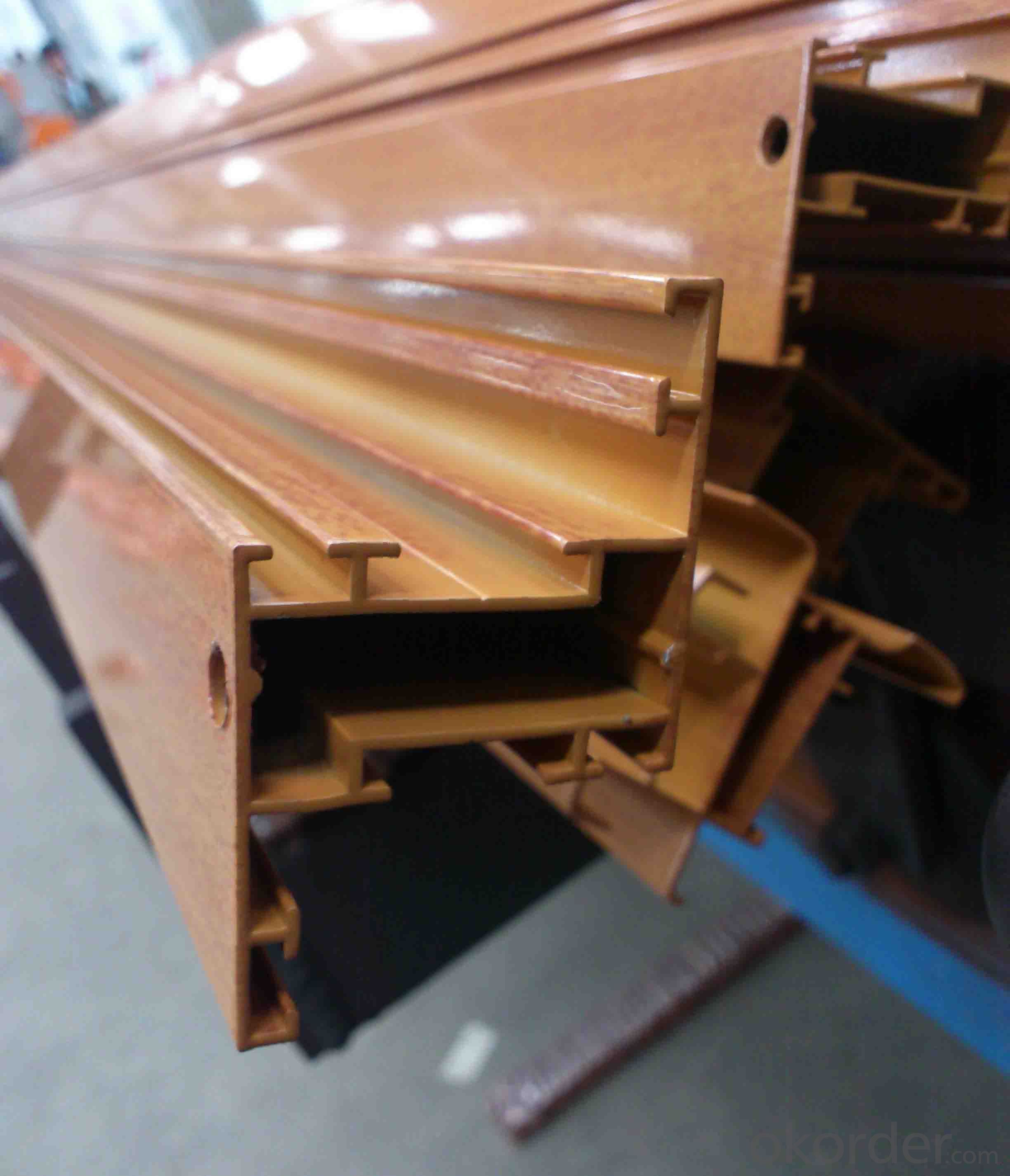

Aluminium profile for Africa

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Aluminium profile

we have the whole window system for Africa Market

Surface:Wood Color

Material: 6063 T5

- Q:Our company purchased aluminum 4-6 meters, many models, what is a good way to make the store that is beautiful and neat, but also conducive to the show?

- 1, if the amount of each model is relatively small, only a few words, as upstairs said, to make some of the following relatively heavy Wang frame (preferably tapered, so that it will not fall);2, if the amount is large enough to do some U type material frames, each frame to make a card, may the material box pile up;

- Q:What are the major factors determining the quality of aluminum profiles?

- Material, section size, fit tolerance, surface treatment quality, etc.

- Q:Can aluminum profiles be an alternative to steel or iron?

- Yes, aluminum profiles can be a viable alternative to steel or iron in certain applications. Aluminum is lightweight, corrosion-resistant, and has high strength-to-weight ratio, making it suitable for various industries including aerospace, automotive, construction, and marine. Additionally, aluminum profiles offer excellent thermal and electrical conductivity properties. However, steel or iron may still be preferred in applications requiring higher tensile strength or extreme durability. Ultimately, the choice between aluminum profiles and steel or iron depends on the specific requirements and constraints of the project.

- Q:Are there any specific safety precautions when working with aluminum profiles?

- Working with aluminum profiles requires specific safety precautions that should be considered. Here are some important precautions to keep in mind: 1. Personal Protective Equipment (PPE): It is vital to wear appropriate PPE, such as safety glasses, gloves, and protective clothing, to safeguard against potential injuries. Aluminum chips or shavings can cause cuts or abrasions. 2. Ventilation: Ensure that the working area has proper ventilation to prevent the accumulation of aluminum dust or fumes. Aluminum dust can be combustible, and inhaling aluminum fumes can result in respiratory problems. 3. Fire Safety: Due to its high flammability, it is crucial to have fire prevention measures in place. Keep a fire extinguisher nearby and avoid sparks or open flames near aluminum profiles. Choose non-sparking tools and be cautious of excessive heat during cutting or welding processes. 4. Handling and Storage: Aluminum profiles can be heavy, so it is important to use correct lifting techniques to avoid back or muscle injuries. Store aluminum profiles securely and in an organized manner to minimize the risk of tripping or falling. 5. Cutting and Machining: When cutting or machining aluminum profiles, use appropriate tools and techniques. Ensure that the material is securely clamped before any cutting operation to prevent movement and potential accidents. 6. Ergonomics: Prioritize maintaining good ergonomics while working with aluminum profiles to reduce the risk of repetitive strain injuries or musculoskeletal disorders. Utilize ergonomic tools or equipment to minimize strain on the body. 7. Training and Knowledge: It is essential to undergo proper training and acquire knowledge about working with aluminum profiles. Understand the specific properties of aluminum and the associated hazards to work safely and efficiently. By adhering to these safety precautions, the risk of accidents, injuries, or health hazards when working with aluminum profiles can be significantly reduced.

- Q:Are aluminum profiles suitable for use in chemical processing environments?

- Aluminum profiles prove to be a suitable option for utilization within chemical processing environments. This versatile and corrosion-resistant material possesses the ability to endure exposure to a vast array of chemicals. Its exceptional resistance extends to numerous common chemicals, encompassing acids, bases, and solvents. Furthermore, aluminum profiles can acquire additional protection through the application of specialized coatings or finishes, like anodizing, which heightens their resistance against chemical corrosion. Moreover, within chemical processing environments, aluminum profiles present other advantages, such as their lightweight composition, high strength-to-weight ratio, and simple fabrication techniques. These qualities render aluminum profiles a favored choice for various applications in chemical processing industries, including the construction of tanks, piping systems, and process equipment.

- Q:Are aluminum profiles suitable for food processing or storage facilities?

- Yes, aluminum profiles are suitable for food processing or storage facilities. Aluminum is a highly versatile material that offers several advantages in these environments. Firstly, aluminum is corrosion-resistant, ensuring that it remains unaffected by moisture, food acids, or cleaning agents commonly used in food facilities. This makes it ideal for use in areas where hygiene and cleanliness are crucial. Secondly, aluminum profiles are lightweight yet sturdy, making them easy to handle and install. This is especially beneficial in food processing facilities where regular equipment maintenance and reconfigurations are required. Additionally, aluminum is a non-toxic material, ensuring that it does not contaminate food products during processing or storage. It is also an excellent conductor of heat, allowing for efficient temperature control in processing facilities. Furthermore, aluminum profiles can be easily cleaned and sanitized, reducing the risk of bacterial growth and ensuring compliance with food safety regulations. Overall, the durability, corrosion resistance, lightweight nature, non-toxicity, and ease of maintenance make aluminum profiles an excellent choice for food processing or storage facilities.

- Q:5002 and 6063 aluminum profiles difference

- 6063 is generally used in architectural profiles.The main alloy elements of 5002 aluminum alloy are magnesium and silicon, and form Mg2Si phase. If it contains a certain amount of manganese and chromium, it can neutralize the bad action of iron.

- Q:Can aluminum profiles be used for electrical bus ducts?

- Yes, aluminum profiles can be used for electrical bus ducts. Aluminum is a suitable material for bus ducts as it is lightweight, corrosion-resistant, and has good electrical conductivity. Additionally, aluminum profiles can be easily fabricated and installed, making them a popular choice for electrical bus ducts in various industries.

- Q:What are the different surface treatments for aluminum profiles?

- Some of the different surface treatments for aluminum profiles include anodizing, powder coating, painting, and polishing.

- Q:How do aluminum profiles perform in earthquake-resistant structures?

- Aluminum profiles perform well in earthquake-resistant structures due to their lightweight yet strong properties. They have high strength-to-weight ratio, which helps in reducing the overall weight of the structure while providing sufficient strength to withstand seismic forces. Additionally, aluminum is highly ductile and can absorb a significant amount of energy during an earthquake, thereby reducing the risk of structural failure. Furthermore, aluminum profiles can be easily fabricated and assembled, offering flexibility in design and construction. Overall, aluminum profiles contribute to the resilience and performance of earthquake-resistant structures.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium profile for Africa

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords