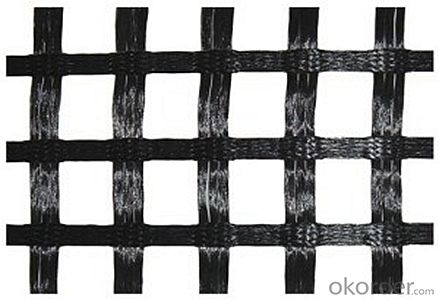

Reinforcement and Separation Fiberglass Geogrid

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Main application objects of the materials:

Reinforcement of highways slopes and higher steepness slopes fixation;

Bed fixation of the various types of road surfacing;

Reinforcement of littoral zone of water reservoirs and greek beds;

Fixation of the railroad cone slopes;Support wall construction.

“Technostroytex” LLC geogrids are a honeycomb of polyethylene bands of 1.7 mm thickness (standard), bound by ultrasonic welding joints chequerwise.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:Geotextile and non-woven fabrics What is the difference

- Geotextile is divided into two non-woven geotextile and woven geotextile, non-woven geotextile and acupuncture and spunlace, staple fiber and long fiber. Nonwovens means that the manufacturing process does not require weaving. Geotextiles are used for geotechnical engineering. Geotextile is part of the textile does not require the manufacture can be made, called non-woven geotextile. Non-woven fabrics can be used very broad, like we use the heart of the soft wipes, are non-woven, as well as the hotel put the shoes of the shoes, but also non-woven.

- Q:Are geotextiles suitable for use in wetlands?

- Yes, geotextiles are suitable for use in wetlands. They are commonly used to stabilize soil, control erosion, and improve water quality in wetland areas. Geotextiles help to retain soil and prevent sediments from entering the water, while still allowing water to pass through and maintain the natural hydrological processes of the wetland.

- Q:What type of geotextile is used for soccer field

- Generally with permeable geotextile, 200g300g can be

- Q:Can geotextiles be used in riverbank stabilization applications?

- Yes, geotextiles can be used in riverbank stabilization applications. They are commonly used to prevent erosion and provide stability to riverbanks by reinforcing the soil and preventing sediment movement.

- Q:Geotextile standard is broken how low?

- Geotextile of the top of the strong implementation of the national standard GB / T-2008, the standard of the geotextile bursting strength requirements in the international arena is not very low. Geotextile because it is produced by fiber acupuncture, and its breaking strength and elongation at break for the main performance indicators, even in practical applications when we are mainly using these two characteristics of geotextile. Breaking strength is called CBR bursting strength, the main test is the product of anti-puncture, the general waterproof, impermeable material requirements are higher, and geotextile is the filter, the protection of materials, so the standard requirements are lower.

- Q:What is the meaning of the geotextile What is its working principle

- Hot geotextile cloth is to isolate the heat and cover a layer of geotextile material. Advantages: light weight, the overall continuity is good, high tensile strength, corrosion resistance, anti-microbial erosion is good, easy construction. Non-woven geotextile properties: small pore diameter, good permeability, soft texture, and soil with a good combination. 2, construction (1) according to the embankment or base wide full section laying. (2) leave sufficient anchorage length on each side of the embankment or substrate. (3) To ensure integrity, when the lap method is continuous, the lap length should be 0.3 ~ 0.5m. When the seam is connected, the bond width is not less than 50mm. (4) site construction, material damage must be immediately repaired. Upper and lower seams should be alternately staggered, staggered length of not less than 0.5m. (5) try to avoid prolonged exposure.

- Q:How do geotextiles affect soil nutrient availability?

- Geotextiles can enhance soil nutrient availability by promoting better water and air circulation, preventing soil erosion, and increasing organic matter content. This allows for improved nutrient uptake by plants and reduces nutrient leaching, ultimately leading to healthier and more fertile soils.

- Q:Can geotextiles be used in coastal protection projects?

- Yes, geotextiles can be used in coastal protection projects. Geotextiles are permeable fabrics that can effectively control erosion and stabilize soil in coastal areas. They are commonly used to prevent sediment loss, promote vegetation growth, and provide shoreline protection against wave action. Geotextiles can be installed as a barrier or a filter to retain sediment and prevent erosion, making them a valuable tool in coastal protection projects.

- Q:Construction Technology of Seepage Control of Geotextile for Landscape Water System

- Laying HDPE geomembrane should try to weld at least, in ensuring the quality of the premise, as far as possible to save raw materials. But also easy to ensure quality. The lap width of the joint between the membrane and the membrane is generally not less than 10 cm, usually in the direction of the weld arrangement parallel to the maximum slope, that is, along the slope direction. Geomembrane thickness of not less than 0.25mm, too thin may produce pores, and easy to damage in the construction and reduce the anti-seepage effect. Geomembrane construction, in particular, should pay attention to laying should not be too tight, not wrinkled, stitching to be strong. Should be strictly in accordance with technical specifications construction, the good preparation, laying, splicing, inspection and backfill, such as five quality off. I specialize in production and construction

- Q:What are the cost implications of using geotextiles in construction projects?

- The cost implications of using geotextiles in construction projects can vary depending on various factors such as the type and quality of geotextile used, the size and complexity of the project, and the specific requirements of the site. However, in general, the use of geotextiles can lead to cost savings in construction projects. Geotextiles can reduce the need for traditional construction materials, such as aggregate and soil, by providing reinforcement, stabilization, and separation functions. This can result in reduced material costs and construction time. Additionally, geotextiles can help improve the longevity and performance of structures, reducing the need for maintenance and repair in the long run. While there may be initial costs associated with purchasing and installing geotextiles, the overall cost benefits and improved project outcomes often outweigh these expenses.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Reinforcement and Separation Fiberglass Geogrid

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords