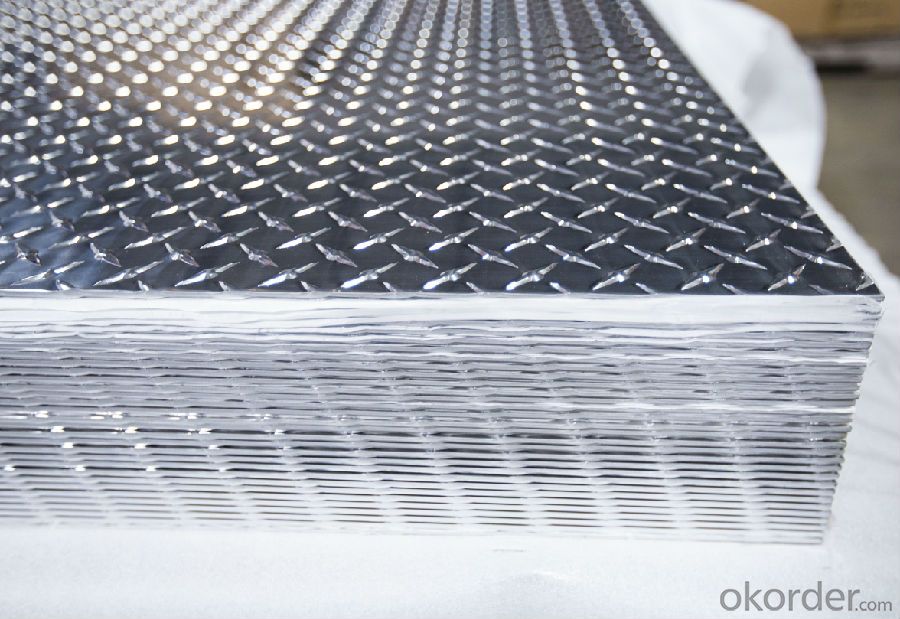

Bright One Bar Aluminum Patio Cover Sheets 3003 H14

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

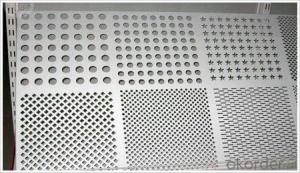

1.Structure of Bright One Bar Aluminum Sheet/Coil 3003 H14 :

Bright One Bar Aluminum Sheet/Coil 3003 H14 is widely used for decorative purposes in construction, packing and appliance. Bright One Bar Aluminum Sheet/Coil 3003 H14 is also very commonly used for anti-shippery purposes in vehicles and pulic places.

2.Main Features of the Bright One Bar Aluminum Sheet/Coil 3003 H14 :

• Beautiful parten

• Good anti-slippery quanlity

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

3. Bright One Bar Aluminum Sheet/Coil 3003 H14

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: what's the difference between the knocking voice of aluminum sheet and stainless steel?

- The voice of aluminum sheet is toneless, and the voice of stanless steel is more crisp.

- Q: Can 101 aluminum sheets be bent without cracking or breaking?

- No, it is highly unlikely that 101 aluminum sheets can be bent without cracking or breaking.

- Q: Does aluminum sheet require special handling during transportation?

- Transporting aluminum sheets requires special handling due to their lightweight nature and susceptibility to damage if mishandled. To prevent scratching, bending, or denting, it is necessary to take specific precautions. Packaging and securing the sheets in a manner that restricts movement and offers sufficient protection against impacts is crucial. Furthermore, it is important to transport aluminum sheets separately from heavy objects or materials to avoid potential damage caused by their weight. In conclusion, ensuring the safe transportation of aluminum sheets necessitates giving them special care and attention.

- Q: How do you ensure the flatness of an aluminum sheet?

- To ensure the flatness of an aluminum sheet, it is important to follow certain steps. First, the sheet should be properly stored and handled to prevent any bending or warping. Next, it should be placed on a flat and level surface during cutting or machining processes. Additionally, using proper clamping techniques while machining or during any further processing can help maintain flatness. Lastly, inspecting the sheet for any signs of bowing or warping and taking corrective measures such as annealing or stress relieving if necessary, can help ensure the flatness of the aluminum sheet.

- Q: Is it possible to use aluminum sheets as a material for the exterior walls of high-rise buildings?

- <p>Yes, aluminum sheets can be used for exterior walls in high-rise buildings. They are lightweight, durable, and resistant to corrosion, making them suitable for such applications. Aluminum sheets can also be coated or anodized to provide additional protection and aesthetic appeal. They are often used in combination with other materials or as a cladding system to enhance the building's appearance and energy efficiency.</p>

- Q: Are aluminum sheets suitable for roofing?

- Indeed, aluminum sheets prove to be a fitting choice for roofing purposes. Renowned for its lightweight nature, durability, and corrosion resistance, aluminum stands out as a favored material in the roofing industry. Moreover, its non-combustible properties render it a safer alternative. The ease of installation and maintenance further add to its appeal, as do its ability to withstand adverse weather conditions like heavy rain, snow, and wind. Notably, aluminum also earns accolades as an environmentally conscious option, boasting 100% recyclability. In summary, aluminum sheets offer a trustworthy and enduring roofing solution for both residential and commercial edifices.

- Q: What are the different types of surface treatments available for aluminum sheets?

- Aluminum sheets can be treated in a variety of ways to achieve specific purposes and unique characteristics. Anodizing, painting, powder coating, and polishing are some of the most commonly used surface treatments for aluminum sheets. Anodizing involves the creation of a thick oxide layer on the surface of the aluminum sheet. This treatment not only enhances the appearance by providing a range of colors but also increases corrosion resistance and durability. Anodized aluminum sheets are widely utilized in architecture, automotive parts, and electronics. Painting is another popular surface treatment for aluminum sheets. It entails applying a layer of paint to enhance appearance and provide additional protection against corrosion and wear. Painted aluminum sheets are commonly seen in signage, building facades, and decorative applications. Powder coating is a type of surface treatment where a dry powder is applied to the aluminum sheet and then heated to create a protective layer. This treatment offers excellent durability, resistance to weathering, and a wide range of color options. Powder coated aluminum sheets find extensive use in the construction industry, as well as for automotive parts and appliances. Polishing involves buffing the aluminum sheet to create a smooth and reflective surface. This treatment enhances the aesthetics, making it perfect for decorative applications like furniture, jewelry, and architectural accents. In summary, the selection of surface treatment for aluminum sheets depends on desired appearance, functionality, and application requirements. Each treatment provides distinct advantages and characteristics, allowing for versatility and customization in various industries.

- Q: Can aluminum sheets be used for storage tanks?

- Yes, aluminum sheets can be used for storage tanks. Aluminum is a lightweight and corrosion-resistant material, making it a suitable choice for storing various substances such as water, chemicals, and fuel. It offers excellent durability and can withstand harsh environmental conditions. Additionally, aluminum tanks are relatively easy to construct and maintain. However, it is important to consider the specific requirements of the substance being stored and consult with experts or engineers to ensure that aluminum sheets are the appropriate choice for the storage tank in question.

- Q: How many square meters does the aluminum plate engrave?

- The price of aluminum sheet is calculated according to the price of aluminum ingot + processing fee (aluminum plate state), and the specific price is also different according to the size and size of aluminum sheet. If you have any questions, please ask, thank you.

- Q: How are aluminum sheets manufactured?

- Rolling is the process by which aluminum sheets are made. It begins with aluminum ingots that are heated and then passed through rolling mills. These mills, made of steel, have rotating rollers that squeeze and stretch the aluminum as it passes between them. This continuous rolling process refines the grain structure of the aluminum and improves its mechanical properties. To ensure the desired thickness and surface finish, the aluminum sheets may go through multiple passes in the rolling mills. Each pass gradually reduces the sheet's thickness until the desired thickness is reached. The final pass also gives the sheet its desired surface finish. After rolling, the aluminum sheets may undergo additional treatments like annealing or surface treatments. Annealing involves heating the sheets to a specific temperature and slowly cooling them to improve their strength and relieve internal stresses. Once manufactured and treated, the aluminum sheets are typically cut into desired sizes and shapes. This can be done through shearing with sharp blades or using specialized cutting machines. In summary, the manufacturing of aluminum sheets is a precise and intricate process that involves heating, rolling, treating, and cutting the aluminum to achieve the desired thickness, finish, and properties.

Send your message to us

Bright One Bar Aluminum Patio Cover Sheets 3003 H14

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords