BMT Rolled Prepainted Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

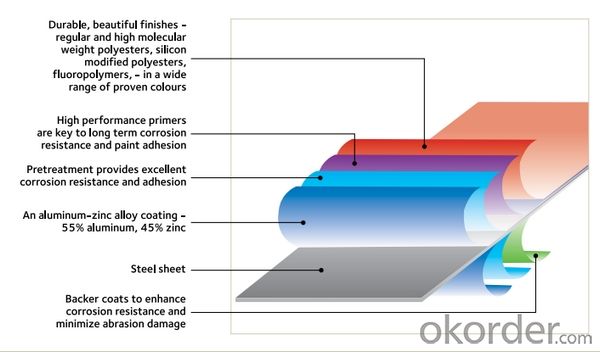

Structure of BMT Rolled Prepainted Steel Coil for Construction

Description of BMT Rolled Prepainted Steel Coil for Construction

BMT Prepainted Rolled Steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Zn coating on both faces by hot dip process. Its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of BMT Rolled Prepainted Steel Coil for Construction

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

3. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of BMT Rolled Prepainted Steel Coil for Construction

1. Construction and building: roofing; ventilating duct; handrail; partition panel

2. Electric appliance: refrigerator; washing machine; refrigerator..

3. Transportation: oil tank; road sign; etc.

4. Agriculture:barn; etc.

5. Others: vending machine; game machine; etc.

Specifications of BMT Rolled Prepainted Steel Coil for Construction

Product | BMT Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.3-3.5mm |

Width | 600-1250mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z35-150g/m2 |

Technique | Raw material: Hot rolled steel coil > Cold rolled>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 25MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of BMT Rolled Prepainted Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. What is your MOQ ?

Our MOQ is 50mt. And there is more discount if you order like 1000 tons and more. The more appropriate payment term your can offer, the better price we can provide.

2. What is the general delivery time?

Usually it is within thirty working days after received buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 20- 25 days, but the shipment will depend on the vessel situation.

3. How do you promise the quality of the steels?

We have established the international advanced quality management system ,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. What different between PE and PVDF?

PVDF is the most advanced painting in construction industry, it is with high corrosion resistance and color retention, and the life time could last to 20-25 years. Currently, PE is the most widely-used painting in the color coated steel coils. It is characterized by good overall performance, and high economic as well

- Q: What are the different types of steel coil packaging techniques?

- There are several types of steel coil packaging techniques, including banding, strapping, shrink wrapping, and palletizing. Banding involves securing the coil with metal bands, while strapping uses plastic or steel straps. Shrink wrapping involves wrapping the coil with plastic film and applying heat to shrink it tightly. Palletizing involves stacking the coils on a pallet and securing them with stretch wrap or straps. These techniques help protect the coils during transportation and storage.

- Q: Which is more reactive? Zinc or Steel? And why?

- Zinc. Steel is an alloy consisting mostly out of iron, In the reactivity seris, zinc is more reactive than iron. Therefore, zinc is more reactive than steel

- Q: What are the different types of steel coil handling equipment used during processing?

- There are several types of steel coil handling equipment used during processing, including coil cars, coil upenders, coil tilters, coil transfer cars, coil grabbers, coil lifters, and coil reels. These machines are designed to efficiently handle and maneuver steel coils of various sizes and weights, ensuring safe and smooth operations during the processing stages.

- Q: What are the different methods of oiling steel coils?

- There are several different methods of oiling steel coils, each with its own unique advantages and applications. Some of the common methods include: 1. Immersion or bath oiling: This method involves submerging the steel coils into a bath of oil. The coils are typically passed through a series of rollers to ensure even coating and complete coverage. Bath oiling is a cost-effective and efficient method for large-scale production, as it can oil multiple coils simultaneously. This method is commonly used for hot-rolled coils. 2. Roll-on oiling: As the name suggests, roll-on oiling involves applying oil to the surface of steel coils using a set of rotating rollers. This method ensures uniform oil distribution and is suitable for both cold-rolled and hot-rolled coils. Roll-on oiling is often preferred when precise control over the amount of oil applied is required. 3. Spray oiling: In spray oiling, a fine mist or spray of oil is applied to the coils using specialized nozzles or sprayers. This method allows for targeted application, making it suitable for specific areas or sections of the steel coils. Spray oiling is commonly used for precision or specialty coils where controlling the amount of oil is critical. 4. Electrostatic oiling: Electrostatic oiling involves applying a charged mist of oil particles to the steel coils. The coils are given an opposite charge, causing the oil particles to be attracted and adhere to the surface. This method ensures an even and controlled distribution of oil, minimizing waste and reducing environmental impact. Electrostatic oiling is often used for high-quality or high-precision applications. 5. Brush or roller oiling: This method involves manually applying oil to the coils using brushes or rollers. It is typically used for smaller-scale operations or when precision is required in specific areas. Brush or roller oiling allows for close control over the amount of oil applied. The choice of oiling method depends on various factors such as the type of steel, desired level of oil coverage, production volume, and cost considerations. Each method has its own advantages and limitations, and manufacturers often select the most suitable method based on their specific requirements and objectives.

- Q: How are steel coils used in the production of steel bolts?

- Steel coils are used in the production of steel bolts by being uncoiled and then fed into a machine that cuts and forms the bolts. The coils provide a continuous supply of high-quality steel, ensuring consistent and precise production of bolts.

- Q: How long do steel coils last?

- The durability of steel coils can differ based on different elements, including the steel's quality, the storage or usage conditions, and the specific application. Typically, top-notch steel coils can endure for numerous years or even decades before exhibiting any signs of deterioration or wear. Nevertheless, it is essential to acknowledge that if steel coils are not adequately maintained or shielded from moisture or harsh surroundings, they can be prone to corrosion. Consequently, consistent inspection, maintenance, and appropriate storage or usage methods play a pivotal role in optimizing the lifespan of steel coils.

- Q: What are the different methods of cutting steel coils into sheets?

- There are several methods used to cut steel coils into sheets, including shearing, slitting, and laser cutting. Shearing involves using a large, powerful machine to cut through the coil with a straight blade. Slitting involves passing the coil through a set of circular blades that gradually reduce its width, creating multiple narrower sheets. Laser cutting uses a high-powered laser beam to precisely and rapidly cut through the coil, offering a versatile and efficient method.

- Q: Aluminum alloy rolling doors and color steel shutter door that good

- Aluminum Alloy shutter door instead of the traditional rolling door noise inherent shortcoming, the process of opening and closing of windleavesthe sound {(Note: the design of Aluminum Alloy shutter doors from the beginning not to seal, but the curtain sheet with a silencing strip sealinghas been improved, but still did not have the seal. ) the existing Aluminum Alloy shutter door curtain film have two Aluminum Alloy hollow extrusions and Aluminum Alloy filled polyurethane foam materials, extrusiontypecurtain, hardness, making width, protective performance are better than the filling profiles, in accordance with the free choice profile door curtain sheet to the different needs of users.

- Q: What are the different coil cutting machine options available for steel coils?

- There are several coil cutting machine options available for steel coils, each catering to different requirements and specifications. Some of the common options include: 1. Slitting Machine: This machine is used to slit the large steel coils into narrower strips or slits. It typically consists of a circular blade that moves across the width of the coil, cutting it into the desired widths. Slitting machines can handle a wide range of steel coil thicknesses and are commonly used in industries such as automotive, construction, and manufacturing. 2. Cut-to-Length Machine: This type of machine is used to cut steel coils into specific lengths. It is equipped with a shearing mechanism that cuts the coil based on the programmed length. Cut-to-length machines are particularly useful for applications where precise and consistent lengths are required, such as in the production of steel sheets or plates. 3. Rotary Shear Machine: A rotary shear machine is designed to cut steel coils into smaller pieces or squares. It utilizes a rotating drum with multiple cutting blades that shear the coil in a continuous process. This type of machine is often used in industries that require smaller steel pieces for further processing or assembly. 4. Guillotine Shear Machine: This machine is equipped with a large blade that moves vertically to cut steel coils. It is commonly used in applications where high precision and high-speed cutting are required. Guillotine shear machines can handle thicker steel coils and are often employed in heavy-duty industries such as shipbuilding and metal fabrication. 5. Laser Cutting Machine: Laser cutting machines offer a highly precise and versatile method for cutting steel coils. They use a focused laser beam to melt or vaporize the material, resulting in a clean and accurate cut. Laser cutting machines are suitable for a wide range of steel coil thicknesses and can handle complex shapes and patterns. These are just a few examples of the coil cutting machine options available for steel coils. The choice of machine depends on factors such as coil thickness, desired cutting precision, required output volume, and specific application requirements.

- Q: What are the common coil handling challenges?

- Some common coil handling challenges include the difficulty in safely lifting and moving heavy coils, ensuring proper alignment and positioning during handling, preventing damage to the coils or surrounding equipment, and efficiently managing coil storage and retrieval.

Send your message to us

BMT Rolled Prepainted Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords