BMP Z20 PPGI Rolled Steel Coil for Construction Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

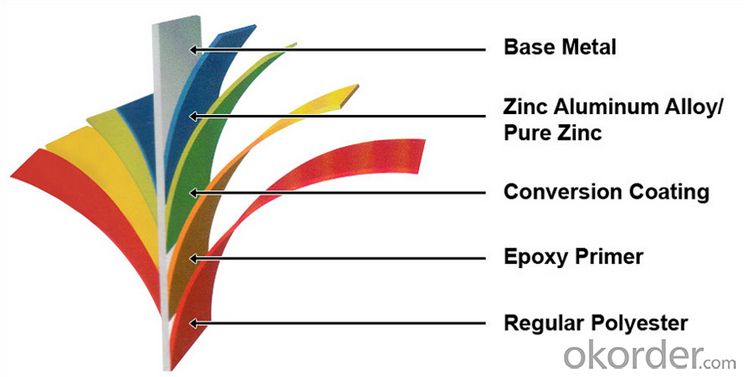

Structure of BMP Z20 PPGI Rolled Steel Coil for Construction Roofing Constrution

Description of BMP Z20 PPGI Rolled Steel Coil for Construction Roofing Constrution

PPGI is made by cold rolled steel sheet and galvanized steel sheets as baseplate, through the surface pretreatment (degreasing, cleaning, chemical conversion processing), coated by the method of continuous coatings (roller coating method), and after roasting and cooling.

Main Feature of BMP Z20 PPGI Rolled Steel Coil for Construction Roofing Constrution

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.

Applications of BMP Z20 PPGI Rolled Steel Coil for Construction Roofing Constrution

1. Our company produce various specification and models and national standards of galvanized steel coil

2. Using high-quality material and advanced production technology and equipment for processing

3.Applicable to a humid climate and the harsh corrosive environment

4. Products has been all over the country more than 20 provinces, municipalities and

autonomous regions, and have been exported to Europe, North American, the Middle East,

the South East Asia, Africa, Asia,European and other countries and regions, well received by our buyer.

Specifications of BMP Z20 PPGI Rolled Steel Coil for Construction Roofing Constrution

Standard | ASTM A653, JIS G3302, GB/T3830-2006 |

Grade | SGCC, DX51D, A653, SGCH, Q235B |

Thickness | 0.125-1.0mm |

Width | 600-1250mm |

Base metal | Galvanized steel coils, Alumzinc steel coils, color coated steel coils |

Zinc coating | 40-275g/M2 |

Coil ID | 508mm/610mm |

Packing | Standard seaworthy export packing: 3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock, with inner coil sleeve. |

Delivery | Within 10-30days after signing contract |

Price | FOB& CNF& CIF price |

Payment terms | TT or LC, Western Union |

Capacity | 1000MT per month |

MOQ | 25MT/20GP |

Usage | construction, the manufacturing of cars, ships, containers and household electric appliances,other industries usage. |

FAQ of BMP Z20 PPGI Rolled Steel Coil for Construction Roofing Constrution

We have organized several common questions for our clients,may help you sincerely:

1. 1.Are you a factory or a trading company?

CNBM is a trading company in this industry over 30 years, located in Beijing

2. Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products..

3.What's your normal delivery time?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: Want to construct a patio cover approx. 20 feet long. Only want to use a 6x6 or 8x8 post at each end. What size steel i-beam would I have to use to carry the load???

- First of all is it a rule of thumb with carpenters and ironworkers never to set steel on wood. I would use a 14 tall (2) ply lvl header. *Laminated veneer Lumber. This will hold the weight of the structure between your posts. A steel beam would be quite costly today as prices on steel have skyrocketed, plus you would need a boom truck or small crane to set this beam, and you would need some sort of mounting bracket or holes pre-drilled in the beam ends to secure it to the posts. Plus you would need to have the beam delivered and if your patio is in the backyard - you would need another pc.of equipment to get it around back. Advice from me is to go with an LVL beam. They are 1+3/4 Thick and you would need a (2 ply ) beam, which means you set one pc. and then laminate another one into the first. Glue between layers (use heavy duty liquid nails) and then Lag screw them together. Use 5/16 x 3 lag screws with a washer on each one. Pre-drill holes about 3/16 smaller than lag screws - then insert lag screws and tighten up with an electric impact.

- Q: How do steel coils contribute to the HVAC industry?

- The HVAC industry relies heavily on steel coils, which play a critical role in the functioning and efficiency of HVAC systems. These coils, often made from high-quality steel like stainless steel or galvanized steel, ensure durability and resist corrosion. One way steel coils contribute to the HVAC industry is by facilitating heat transfer. HVAC systems use coils to transfer heat between the air and a refrigerant. For instance, in air conditioning units, the evaporator coil absorbs heat from the indoor air, while the condenser coil releases heat to the outside air. The steel coils in these units provide a large surface area for efficient heat exchange, allowing for effective cooling or heating of the air. Furthermore, steel coils contribute to the energy efficiency of HVAC systems. By maximizing heat transfer, these coils enable HVAC systems to operate at optimal performance levels while consuming less energy. This not only reduces energy costs for users but also makes HVAC systems more environmentally friendly by minimizing energy consumption and greenhouse gas emissions. Steel coils in HVAC systems also play a role in maintaining indoor air quality. As air passes over the coils, impurities like dust, dirt, or mold can accumulate on the coil's surface. Regular maintenance and cleaning of the coils are essential to prevent the buildup of contaminants that could negatively impact air quality. Properly maintained steel coils ensure clean and healthy indoor air, which is particularly important for commercial buildings, hospitals, and other spaces where air quality is crucial. Additionally, steel coils provide durability and longevity to HVAC systems. Steel is a strong and resilient material that can withstand high temperatures, pressure, and environmental stress. By using steel coils, HVAC systems can operate reliably and efficiently for extended periods, reducing the need for frequent repairs or replacements. Overall, steel coils are indispensable to the HVAC industry. They enable efficient heat transfer, enhance energy efficiency, improve indoor air quality, and provide durability to HVAC systems. Without steel coils, HVAC systems would significantly lose their performance and effectiveness, highlighting the vital role of steel coils in the HVAC industry.

- Q: I heard about a new bike the specialized allez steel. Has anyone heard anything about it. it will have all brand new components like shimano 2300 parts and everything. it looks nice.

- Steel? I doubt it's made out of steel, more labor and a heavier frame. Most likely aluminum. Shimano 2300 you say? The Shimano 2300 is the lowest of the low of Shimano road components. Most likely not too reliable and heavy. www.cyclestore .uk/productDetai... I think this is what you might be looking for.

- Q: What are the common challenges faced in steel coil production?

- Some common challenges faced in steel coil production include maintaining consistent quality control, managing high production volumes efficiently, ensuring proper handling and storage to prevent damage, dealing with fluctuations in raw material prices, and addressing environmental concerns related to energy consumption and emissions.

- Q: How are steel coils processed for edge trimming or slitting during processing?

- Steel coils are processed for edge trimming or slitting during processing by utilizing specialized machinery. The coils are unwound and fed into the machine, where the edges are trimmed off to achieve the desired width. For slitting, the coil is passed through multiple sets of circular blades that cut it into narrower strips. This process ensures precise dimensions and smooth edges, making the steel coils ready for further applications.

- Q: What are the dimensions of steel coils used in the transportation equipment industry?

- The dimensions of steel coils utilized in the transportation equipment sector may differ according to specific demands and applications. Nevertheless, there exist some prevalent measurements that are extensively employed. Typically, the width of steel coils used in the transportation equipment industry ranges from 600mm to 2000mm (24 to 78 inches). This width is selected to ensure compatibility with the machinery and equipment employed in transportation, such as trucks, trailers, and railcars. The thickness of steel coils exhibits significant variation depending on the specific application and desired material strength. However, common thickness ranges for steel coils in the transportation equipment industry generally fall between 0.5mm and 6mm (0.02 to 0.24 inches). The inner diameter of steel coils utilized in the transportation equipment industry is typically standardized at either 508mm (20 inches) or 610mm (24 inches). This standardization facilitates easy handling and compatibility with industry machinery. The outer diameter of steel coils can differ depending on the coil's width and thickness. Nonetheless, typical outer diameter ranges for steel coils in the transportation equipment industry generally span from 1000mm to 2200mm (39 to 87 inches). It should be recognized that these dimensions are not fixed and can be tailored to specific requirements and applications within the transportation equipment industry.

- Q: How is it used easy 10 points just tell me how its used or any intersting facts this is for my comp science paper lol. I know what the hell does steel have to too do with computers he is a Fg! Please be descriptive THANKS! FAST ANSWERS TOO it 9pm bedtime for a 14 year old lol..

- its used in lots of things (cutlery, bridges, engines), and riotinto have made a lot of money from it. and it's an alloy of iron with a bit of carbon in.

- Q: What are the different methods of coil end welding for steel coils?

- There are several different methods of coil end welding for steel coils, which include resistance welding, laser welding, and electric arc welding.

- Q: so my parents gave me stainless steel cookware for christmas and the first time i used it i cooked chicken. it stuck to the pan and where the oil splattered it cooked on and turned it dark black and brownish. and the bottom too. i don't cook with it because i don't want to burn it on anymore but i don't know how to clean it. how do i cook without burning anything, aside from a lower flame and how on earth do i get the stains on. i've tried almost everything too! thanks.

- Use oven cleaner. It will take off the burnt on stuff just like it does in the oven. Spray it on, put the cover on the pot and let it sit for a while. If the problem is on the outside, do the same but put the whole thing in a garbage bag to control the fumes. Wash the pot like you would normally to get the oven cleaner off. You will want to wear gloves too. Oven cleaner is very caustic. By the time you realize you are being burned by it, it's too late. The oven cleaner should do nothing to the finish of the stainless.

- Q: What are the common applications of cold-rolled stainless steel coils?

- Cold-rolled stainless steel coils have various common applications in industries such as automotive, construction, and manufacturing. They are commonly used in the production of appliances, kitchen equipment, roofing, and cladding materials due to their corrosion resistance, durability, and aesthetic appeal. Additionally, cold-rolled stainless steel coils are utilized in the fabrication of pipes, tubes, and structural components, as well as in the production of surgical instruments and medical equipment, owing to their sanitary and hygienic properties.

Send your message to us

BMP Z20 PPGI Rolled Steel Coil for Construction Roofing Constrution

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords