Wholesale Blue Coated Aluminum Foil Coil for Insulated Panels

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Blue Coated Aluminium Foils Used for Insulated Panels

We specialize in Blue Coated Aluminium Foils Used for Insulated Panels . Our coating include blue color, transparent color, gold color, silver color, etc.

Normally we use 1100 H22 as base coils and coated with clear epoxy, which is easily to be stuck with polyurathane and phenolic foam. Usual width include 1210mm, 1215mm, 1270mm, etc.

We have very strict inspection management including inspection for materials, inspection during production and inspection for finished goods.

Our test equipments include optical thickness gauge, cupping test machine, mettle Toledo, tensile-strength tester, busting strength tester, elongation tester, etc.

2.Main Features of Blue Coated Aluminium Foils Used for Insulated Panels

Moisture resistant

Light and easy for installation

Heat preservation

Low thermal conductivity

Durable and corrosion resistance

High heat reflection

Energy Saving

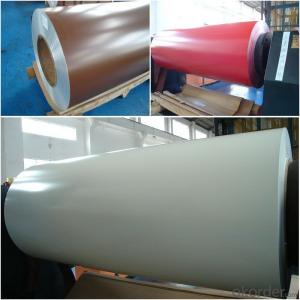

3. Blue Coated Aluminium Foils Used for Insulated Panels Images

4.Specification of Blue Coated Aluminium Foils Used for Insulated Panels

Alloy: 8011/ 1100/ 1235

Temper: O/H18/H22/H24/H26

Thickness & tolerance: 0.007-0.2mm (+/-6%)

Width & tolerance: 200mm-1650mm (+/-1mm)

Mechanical properties: Tensile strength (U.T.S) ≥ 80 MPA, Elongation ≥ 1%

Standard: GB/T3198/ASTM-B209/EN546

5.FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Can aluminum coils be utilized as a material for crafting jewelry?

- <p>Yes, aluminum coils can be used for making jewelry. Aluminum is a lightweight, durable, and affordable metal that is often used in costume jewelry and for decorative purposes. It can be easily shaped, bent, and manipulated into various forms, making it suitable for creating intricate designs. However, it's important to note that aluminum is a softer metal and may not be as durable as other metals like stainless steel or silver, so it may not be ideal for pieces that will be worn daily or subjected to significant wear and tear.</p>

- Q: What are the necessary safety measures to take when handling aluminum oxide coated aluminum coils?

- <p>When working with aluminum oxide coating on aluminum coils, it's crucial to follow safety precautions. Always wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a dust mask to prevent inhalation of dust particles. Ensure proper ventilation to avoid dust accumulation. Handle the material carefully to prevent any skin contact with the coating. Keep the area clean and free from any flammable materials to avoid fire hazards. Be aware of the specific health risks associated with aluminum oxide exposure, and follow the manufacturer's guidelines for safe handling. Regularly inspect equipment for any signs of wear or damage that could lead to accidents.</p>

- Q: What are the standard widths of aluminum coils?

- The standard widths of aluminum coils can vary depending on the specific industry and application. However, in general, the standard widths of aluminum coils range from 12 inches (30.48 cm) to 60 inches (152.4 cm). These standard widths are commonly used in various industries such as construction, transportation, and manufacturing. It is important to note that customized widths are also available in the market to cater to specific project requirements.

- Q: Can aluminum coils be used in the production of heat exchangers?

- Yes, aluminum coils can be used in the production of heat exchangers. Aluminum is a commonly used material in heat exchangers due to its excellent thermal conductivity, lightweight nature, and corrosion resistance. The use of aluminum coils allows for efficient heat transfer and helps in optimizing the overall performance of the heat exchanger.

- Q: Can aluminum coils be used in the manufacturing of electronic devices?

- Yes, aluminum coils can be used in the manufacturing of electronic devices. Aluminum has excellent electrical conductivity and thermal properties, making it suitable for various applications in electronics, such as in transformers, inductors, and heat sinks. Its lightweight nature and corrosion resistance also make it a popular choice for electronic components.

- Q: What are the maximum operating temperatures for aluminum coils?

- The maximum operating temperatures for aluminum coils typically depend on the specific alloy used and the application they are being used in. However, in general, aluminum coils can withstand high temperatures without significant degradation or performance issues. For most common aluminum alloys, such as 3003 and 5052, the maximum operating temperature is around 300-400 degrees Fahrenheit (150-200 degrees Celsius). These temperatures are well within the range of most industrial and commercial applications, including HVAC systems, refrigeration units, and heat exchangers. There are also specialized aluminum alloys, such as 4004 and 4343, that are designed specifically for high-temperature applications. These alloys can withstand temperatures up to 550-650 degrees Fahrenheit (290-340 degrees Celsius) without significant loss of structural integrity or performance. It's worth noting that the maximum operating temperature may vary depending on factors such as the thickness of the coil, the heat transfer conditions, and the duration of exposure to high temperatures. Therefore, it is always advisable to consult the specific manufacturer's guidelines or conduct temperature tests to determine the safe operating limits for a particular aluminum coil in a specific application.

- Q: Can aluminum coils be used for window frames?

- Yes, aluminum coils can be used for window frames. Aluminum is a popular choice for window frames due to its lightweight, durable, and corrosion-resistant properties. It is also easily customizable and can be painted or anodized to achieve different aesthetics.

- Q: What are the different coil packaging materials used for aluminum coils?

- Aluminum coils commonly utilize various coil packaging materials to ensure their protection during transportation and storage, guaranteeing their safe arrival at the desired location. Plastic stands out as one of the most favored coil packaging materials for aluminum coils. Plastic packaging can take the form of shrink wrap, stretch film, or plastic bands. Shrink wrap is frequently employed to envelop the coils tightly, providing them with a secure and protective covering. On the other hand, stretch film is used to securely wrap the coils together, preventing any shifting and potential damage. Plastic bands, meanwhile, are used as an additional layer of stability to secure the coils. Paper is another widely used packaging material for aluminum coils. Kraft paper or corrugated cardboard is often utilized to wrap and protect the coils. This type of packaging offers cushioning to prevent the coils from scratching or rubbing against each other during transit. Moreover, paper packaging is easily recyclable, making it an environmentally friendly choice. In addition to plastic and paper, steel strapping is occasionally employed for packaging aluminum coils. Steel strapping possesses excellent strength and durability, ensuring the coils remain securely bundled during transportation. This type of packaging material is particularly valuable for heavy-duty applications that require extra protection. Ultimately, the selection of coil packaging material for aluminum coils depends on factors such as coil size and weight, transportation requirements, and the desired level of protection. By utilizing the appropriate packaging materials, aluminum coils can be effectively shielded from damage and reach their destination in optimal condition.

- Q: I am a college student living in a private apartment and I use up lots of aluminium foils to cook and eat. I use aluminium foils as plates because I am too lazy to clean plates. I want to know how environment-unfriendly i am for doing so. How bad am I compared to the guy who keeps on drinking from cans without recycling them?

- Aluminium foil is less than 0.2mm thick but typically 0.02mm so a piece 300mm x 100mm has a total volume of 3 x 1 x 2 x 10^2 mm^3 that is 600 mm^3 The density of Al is 2700 kg/m^3 so the mass of your foil is 2700 x 600 /10^9 kg = 0.00162 kg = 1.62 g Modern aluminium cans weigh about 15g I take it you aren't studying either physics or mathematics or you would easily have workd it out!

- Q: Is it possible to utilize a magnetic stirrer to determine the magnetic characteristics of an aluminum coil?

- <p>No, you cannot use a magnetic stirrer to test the magnetic properties of an aluminum coil. Aluminum is a non-magnetic material, meaning it does not respond to magnetic fields in the way magnetic materials like iron, nickel, or cobalt do. A magnetic stirrer operates by creating a rotating magnetic field to stir substances, but since aluminum is non-magnetic, it will not be affected by the stirrer's field. To test magnetic properties, you would need to use materials that are ferromagnetic or paramagnetic, or employ other methods such as a magnetometer for measuring magnetic fields.</p>

Send your message to us

Wholesale Blue Coated Aluminum Foil Coil for Insulated Panels

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords