Best Line Aluminum Coil for Coated Aluminum Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

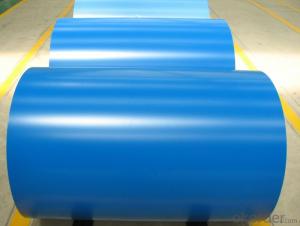

Coated Aluminium Coil/Roll For Aluminium Composite Panel

Description

Alloy | 1060, 1100, 3003, 8011, etc. |

Temper | H16, H18, H24, H26, H28 |

Thickness | From 0.05mm to 3.0mm |

Width | Standard width:1240mm |

Special width:1300mm, 1520mm, 1570mm, 1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, ACRYLIC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness(pencil resistance) | More than 2h |

Coating adhesion | 5J (EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility(T-bend) | 2T |

MEK resistance | More than 100 |

Advantage | 1.High temperature resistant 2.Weathering resistant 3.Scrubbing resistant 5.Acid or alkali proof 6. Fireproof 7.Light weight material is easy to construct and install |

Out package | Wooden splint with export standard |

Application | ACP, wall cladding, facades, roofs and canopies, ceilings, signboards, blind window, display platforms, electrical panels, etc |

Manufacturing

Decoiler → Accumulator →Tension Leveler →Acid & Alkali Cleaner → Rinse →Conversion Treatment → Priming coater →Infrared Curing Oven →Main coater →Floatation Curing Oven →Strippable Film Applicator → Exit Accumulator → Recoiler

FAQ

--Q: Do you provide free samples?

--A: Yes, free samples will be sent to you on freight at destination.

--Q: Can I get your latest products catalogue?

--A: Yes, it will be sent to you in no time.

--Q: What is the MOQ?

--A: 2 tons

--Q: What are your payment terms?

--A: We accept L/C, T/T.

--Q: What kinds of alloy can you supply?

--A: 1000 series: 1050, 1060, 1070, 1100, 1145, 1200

3000 series: 3003, 3004, 3105, 3104

5000 series: 5052, 5083, 5754, 5182

6000 series: 6061, 6063, 6062, 6063

8000 series: 8011, 8021

--Q: What kinds of temper can you supply?

--A: O-H112: O,H12,H14,H16,H18,H22,H24,H26,H,32,H34,H111,H112

T3, T4, T6

- Q: What is the shelf life of aluminum coils?

- The shelf life of aluminum coils can vary depending on various factors such as storage conditions, protective coatings, and exposure to environmental elements. However, in general, aluminum coils can have a shelf life of several years if stored properly in a dry, cool, and non-corrosive environment.

- Q: Can aluminum coils be used in the production of kitchen utensils?

- Yes, aluminum coils can be used in the production of kitchen utensils. Aluminum is a popular choice for kitchen utensils due to its excellent heat conductivity, lightweight nature, and corrosion resistance. It can be easily formed into various shapes, making it suitable for manufacturing utensils like pots, pans, and baking sheets.

- Q: What are the common surface treatments for aluminum coils in the automotive industry?

- In the automotive industry, aluminum coils undergo various surface treatments to enhance their performance and appearance. Some common surface treatments for aluminum coils in the automotive industry include: 1. Anodizing: Anodizing is a popular surface treatment for aluminum coils as it creates a protective oxide layer on the surface. This process involves immersing the coils in an electrolytic solution and passing an electric current through it. Anodizing provides corrosion resistance, improves durability, and allows for the application of dyes or paints. 2. Painting: Aluminum coils can be painted to provide an aesthetically pleasing appearance and protection against environmental factors. The coils are coated with a layer of paint, which can be solvent-based or powder-coated. Painting not only enhances the visual appeal but also adds a layer of protection against scratches and UV radiation. 3. Cladding: Cladding involves bonding a layer of aluminum alloy with different properties onto the surface of the coil. This treatment is commonly used to improve the strength, thermal conductivity, or corrosion resistance of the aluminum coil. Cladding can be done through various methods, such as hot rolling, cold rolling, or explosive bonding. 4. Clear Coating: Clear coating is often applied to aluminum coils to provide a transparent protective layer. This coating helps prevent corrosion, oxidation, and discoloration, while also preserving the natural metallic appearance of the aluminum coil. 5. Polishing and Buffing: Polishing and buffing are surface treatments that aim to enhance the surface smoothness and shine of aluminum coils. These treatments involve mechanically grinding or polishing the surface to remove imperfections, scratches, and oxidation. Polishing and buffing are commonly used for decorative purposes in high-end automotive applications. These are just a few of the common surface treatments for aluminum coils in the automotive industry. The choice of treatment depends on factors such as the desired appearance, performance requirements, and environmental conditions the coils will be exposed to.

- Q: What is the weight of aluminum coils?

- The weight of aluminum coils can vary depending on the specific dimensions and thickness of the coils. However, on average, aluminum coils can range in weight from a few hundred pounds to several thousand pounds. It is important to note that the weight of aluminum coils can also be influenced by factors such as the alloy composition and any additional coatings or treatments applied to the coils.

- Q: Can aluminum coils be used in the production of heat exchangers?

- Yes, aluminum coils can be used in the production of heat exchangers. Aluminum is a popular choice for heat exchangers due to its excellent thermal conductivity, which allows for efficient heat transfer. Additionally, aluminum is lightweight and corrosion-resistant, making it a durable and long-lasting option for heat exchanger applications. The use of aluminum coils in heat exchangers is common in various industries, including HVAC, refrigeration, automotive, and aerospace.

- Q: This question asks about the environmental effects that aluminum coils may have on the environment.

- <p>The environmental impacts of aluminum coils are multifaceted. Aluminum production, particularly the extraction and refining process, consumes significant energy and can result in greenhouse gas emissions. The mining of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. However, aluminum coils are recyclable, which reduces their environmental footprint compared to non-recyclable materials. When recycled, aluminum saves up to 95% of the energy needed to produce new aluminum, reducing emissions and waste. Despite these benefits, improper disposal or incineration of aluminum can still contribute to pollution. Overall, the environmental impact of aluminum coils is complex, with both negative and positive aspects depending on production methods and waste management practices.</p>

- Q: This question seeks advice on methods to prevent rust formation on aluminum coils.

- <p>To prevent rust on aluminum coil, ensure proper storage conditions by keeping the coils dry and avoiding contact with moisture. Use protective coatings or sealants that are compatible with aluminum to create a barrier against the elements. Regularly inspect the coils for signs of corrosion and clean them with a non-abrasive cleaner to remove any contaminants. Avoid using harsh chemicals that could accelerate oxidation. Maintain good ventilation in storage areas to reduce humidity, which can contribute to rust formation. Finally, consider using anodizing or other surface treatments that enhance the aluminum's natural resistance to corrosion.</p>

- Q: How many 1220mm*2440mm aluminum sheets can one-ton aluminum coil be sliced to? Thank you.

- You should know the thickness of aluminum sheet first, and then calculate the weight of aluminum sheet of this specification, and finally use 1T divide the weight.

- Q: Are aluminum coils suitable for decorative purposes?

- <p>Yes, aluminum coils can be used for decoration. They are lightweight, durable, and corrosion-resistant, making them ideal for various decorative applications. Aluminum coils can be shaped and colored to suit different design needs, often used in architectural features, interior design elements, and even in art installations. Their versatility and aesthetic appeal make them a popular choice for both commercial and residential decoration.</p>

- Q: Can aluminum coils be used in the manufacturing of aircraft parts?

- Indeed, the utilization of aluminum coils is feasible in the production of aircraft components. Aluminum possesses favorable characteristics, such as being lightweight, resistant to corrosion, and possessing a high strength-to-weight ratio, which render it a popular choice for constructing aircraft. The pliability of aluminum coils allows for their effortless transformation into diverse shapes, thereby making them suitable for producing various elements of an aircraft, including fuselage panels, wings, and structural parts. These coils can undergo further processing techniques such as rolling, extrusion, and forming to attain the necessary dimensions and structural integrity required for aircraft components. Furthermore, aluminum's proficient ability to conduct heat and electricity proves valuable in applications where temperature regulation and electrical conductivity play a crucial role, such as in heat exchangers and electrical wiring systems within an aircraft. All in all, aluminum coils represent a versatile and extensively utilized material in the aircraft parts manufacturing industry.

Send your message to us

Best Line Aluminum Coil for Coated Aluminum Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords