Basalt Continuous Roving - High Quality Fiberglass Woven Roving Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

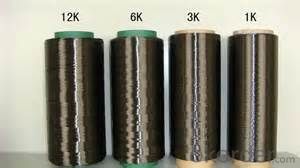

Basalt fiber roving is collective beam,which combine stranded parallel protofilament with sub-thread thread parallel protofilament in no woven condition.

specifications :

1.Tensile strength of the roving 7-13μ Woven roving ≥ 0.65N/Tex

2.Elastic modulus is ≥ 95GPa

3.Elongation at break ≥ 2.6%

4.High temperature and light resistance.

Assembled roving represent an untwisted strand, made up of several evenly strained complex yarns.

Rovings are manufactured according to Technical Specifications 5769-026-00204990-2005.

Assembled roving represent an untwisted strand, made up of several evenly strained complex yarns. Complex yarns for assembled roving are made of basalt crumb.

Example of assembled roving: BC11320W-76(64)

B – raw material – basalt crumb.

C –continuous yarn.

11 – nominal diameter of a simple yarn, μm.

320 – nominal linear density of roving, tex.

W – purpose of roving: W – for weaving.

76 – type of silane sizing.

64 – nominal linear density of a complex yarn, composing roving.

Field of application:

1. Manufature of basalt fabrics;

2. Manufacture of basalt plastics;

3. Manufacture of bodies of rotation: pipes for chemical, oil and gas industries, pressure relief pipes, tanks (made by winding) for storage and transportation of chemically active substances, waterm combustive-lubricating products.

4. For reinforcement of plastics and concrete.

5. In production of geotextile nets and canvases, serving for reinforcing of asphaltic concrete pavement, by improving durability and split-resistance.

packages :

in carton with pallets

FAQ:

1.What is the delivery time ?

We can promise you a short lead time ( 10-15days )

2.Are you a factory?

We have factory and can offer you direct price,and we have 10 yeas experiences

- Q: The difference between the BMC and DMC DMC?

- DMC is an ordinary premix molding compound with flame resistance and insulation. As continuously promotion, its social demand increases rapidly in United States. BMC has many different names.It mainly uses the polyester molding compound for production. Such great value and vitality of the new materials like BMC will play an increasingly important role in a wide range of areas. DMC is also known as the BMC. Although the development and application of BMC in China started late, it significantly promoted the industrial materials and technological progress. Because of their similar nature and process consistency, bulk molding compound such as DMC has the feature of leakage resistance and rigidity. especially the tensile strength of BMC which is based on unsaturated polyester. BMC refers to modified premix molding compound based on isophthalate polyester resin. With mass production and free coloring, it is irreplaceable for other raw materials. Bulk premix molding compund. In 1989, the development of everthing is inevitable.

- Q: How to make the lining of tank acid-proof and anticorrosion.

- If it is metal can, cleaning, descaling and brushing anticorrosion lacquer will be fine.

- Q: What's the difference between fiberglass roving and spun yarn? Is the production equipment the same?

- The company has advanced production equipment, strong technical force, mainly produces non alkali glass fiber 30 and 40 spun yarn, and produces 1500 tons annually. There are two kinds of paraffin and silane

- Q: Is arbon fiber better than glass fiber reinforced plastic

- Lighter and more toughness.

- Q: What materials are used to the special grid plate of the carwash?

- We call it geogrids with the frame made by the glass fiber twistless roving. The matrix is mainly unsaturated polyester resin

- Q: What kind of knife can used to cut glass wool cloth?

- The mix proportion of epoxy resin and mortar is that 6101epoxy resin: ethylenediamine: cement: sand is equal to 100:15:8:200:500. 1 base dispose, 1)a vertical fissure is formed along the crack gouge, vertical cracks cut into 2 surface treatment, Siyou cloth with its surface sticking epoxy base fluid and glass silk cloth is used for surface treatment ( in which oil used is epoxy liquid, and cloth is glass?silk cloth). 1) process of glass silk cloth. Glass cloth generally usually made by alkali-free glass fiber is twistless roving woven cloth. Wetting agent are added in the production process of glass silk cloth. As wetting agent contains grease and wax which will impact the combination of epoxy base fluid and glass silk cloth, it is necessary to remove oil and wax on glass silk cloth in order to make epoxy base fluid immerse in glass fiber, improving the bonding effect. The method for removing wax and oil is to place glass silk cloth in boiling water containing with soda for an hour, then you should blanching it with clean water. the way to judge whether there is oil and wax on glass silk cloth is to touch and feel it. If you feel like it is not greasy, it is clean. After removing oil and wax, glass silk cloth losts its original white and brightness appearance and its weight also reduces correspondingly. 2) paste process. When pasting, you should brush epoxy resin base fluid evenly on the paste face, then you should brush the second layer with the same way.

- Q: What is the difference glass fiber roving and fine yarn ? Does the equipment used for production have any difference.

- 6 microns non-alkali, 9 micron twistless roving (bulk yarn), 80 alkali , 30 twist roving ans 21 medium alkali. It is a glass fiber integrated production enterprises combined management, scientific research and development. The company has advanced production equipment and strong technical force. Main production includes 30 alkali-free glass fiber yarn and 40 fine yarn with annual production of 1500 tons.

- Q: What is grc material?

- Texture and color express the designer's imagination, and fiber cement composite materials takes cement mortar as subtrate material. [Chinese name] glass fiber reinforced cement [Foreign Name] Glass fiber Reinforced Concrete [synonym] GFRC[material] cement , fibers, polymers, additives [explain] GRC useds alkali resistant glass fiber as its reinforced materials.

Send your message to us

Basalt Continuous Roving - High Quality Fiberglass Woven Roving Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords