Ball Valve For Heating Supply PN 4 Mpa high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ball Valve For Heating Supply

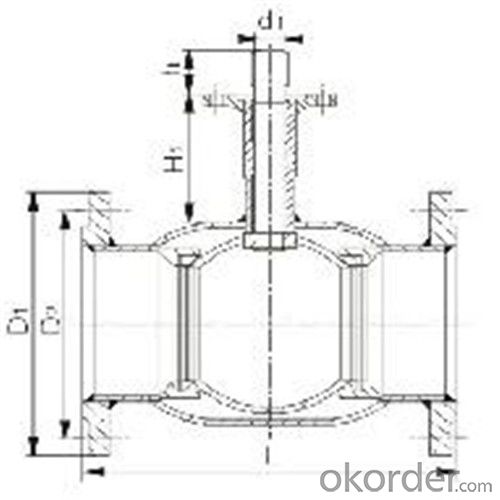

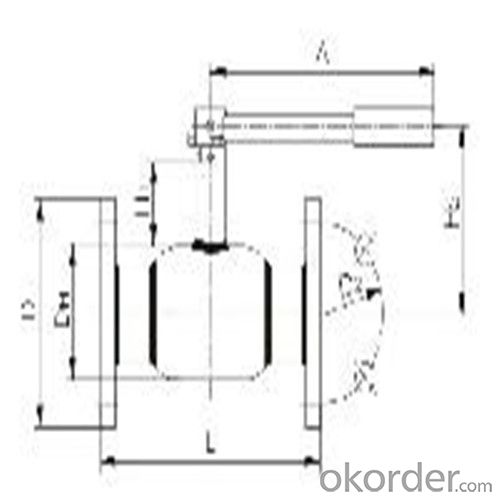

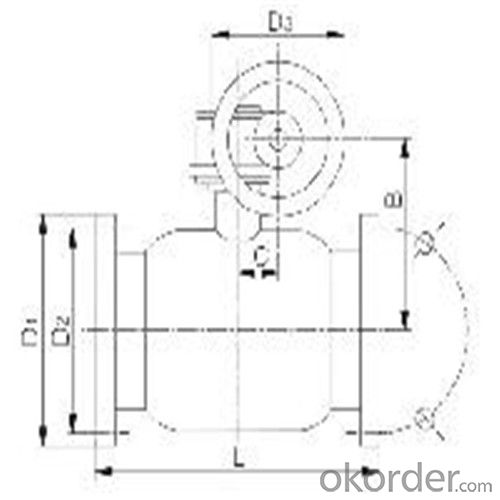

Product Description of Ball valve for heating supply:

Technical introduction

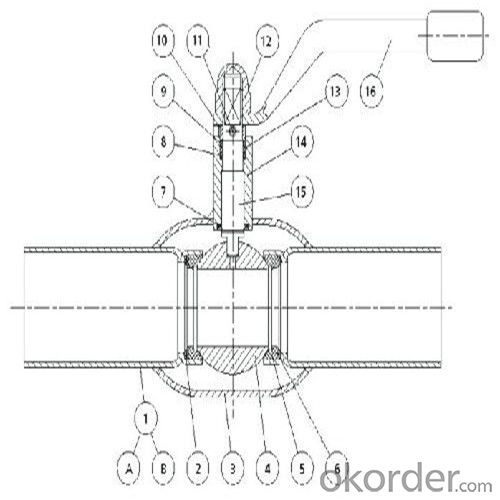

★The ball valve is designed as fully welded structure,which can prevent the leakage of medium.

★The valve seat is floating and spring-loade.The seal is made of soft seal materials of PTFE+20%C and Viton B.The seat is tightly abutted against the ball surface by the pressure of a spring,so that even if the media is in low pressure,a reliable sealing can be assured for the ball valve.Double piston effect and double seal(two-seal seat)are adopted in specially designed valve seat to realize double sealing,which makes the tightness of the ball valve more advantageous and the operation easier.

★A floating ball is adopted for DN15-DN200,and a stem and trunnion ball is adopted for DN200 and above,which can ensure the accurate position of different size ball.In other words,the sealing performance,low torque valve and operability can be guaranteed.

★The sealing of the stem is fulfilled by two replaceable O-rings and packing consisting of PTEE+20%C or flexible graphite,as the packing seal material,is fire proof effect,and is specially suitable for fuel gas systems.

★The materials used for the valve body and pipelines are the same(carbon steel or SS steel),valve body and stem adopt SS steel and the packing adopts PTEE+20%C which is corrosion-resistance or flexible graphite.

Design Features of Ball valve for heating supply:

Features and Applications

Raymond's fully welded ball valve for heating supplyand Fuel Gas systemare used to control the flow at fully open or closed position,not regulate the flow.Only special types of ball valves can realize the flow regulation.Therefore,our welded ball valves can satisfy the requirements of heating systems,e.g:

★Main pipelines of heating equipment

★Cross channels of heating pipes

★Heat exchanger station and any long distance operating station,e.g:

For the transmission of hot water and two kinds of mixed media(water,air or natural gas),limited to Max.4.0MPa and 200°C.

For the transmission of natural gas and one medium,from -30°C to 60°C,and even up to 150°C using specially designed ball valves.

★Coal gas pipelines,trunk and the branch supply lines.

Standard of Ball valve for heating supply:

Actuator | Gear Handwheel customize |

Connection | Flange SW Weld customize |

Medium | Gas Natural gas Water customize |

Medium Temperature | <200< span="">℃ customize |

Application Fields | Electricity Medical Petrochemical customize |

Connection Standard | EN 1092-1 EN 12627 ISO 7-1 customize |

FAQ of Ball valve for heating supply:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: I've been playing french horn in school for about five years, and I'm not exceptional by any means! But I love the instrument. Our school district bought a french horn a few years ago when we didn't have enough french horns for players. The almost new Holton has great tone. But unfortunately it fell into ignorant hands and has been neglected for two years. I just received the instrument and cleaned it up and got it back up to snuff, except for the valves. I can't get them to run smoothly!! They act all gummed up. I've put oil in the top and bottom of the valve, and I've dropped a couple drops in the tubes down onto the valves, but they're still gummed up! Do I need to use more oil?? Or what? Any suggestions?

- Here are 3 options I know of - 1) take it in and have it cleaned. This can cost anywhere upwards from $40. I paid $75 last time. 2) Clean it yourself. Take out all the slides, pour a few drops of dishwashing liquid soap into each valve (one at a time). Get it all the way through, like you would when using oil. Use warm water and rinse out all the soap. Let it dry. This is very tedious, but has worked for me the couple times I've done it. 3) Like someone else said, use a thinner valve oil to semi-rinse out the gumminess. This has also worked well for me. Keep the lead pipe clean!

- Q: When I flush the toilet it flushes just fine, but it doesn't fill again. You have to close the wall valve and then open it up again to fill the tank. Is this a problem with the valve or the internals of the tank? Thanks

- Check your fill valve (inside the tank) first. If it appears to be working properly, turn the water off outside the house, drain the tank, take the filler tube ( from the valve to the bottom of the tank on the outside) loose at the valve. Remove the valve and inspect for obstructions, such as calcium and or lime deposits. You may need to replace the valve as they will occasionally wash out over time. Reverse this process to put everything back together, and be sure to wrap the male threads on the supply line (pipe sticking out of the wall) with teflon tape.

- Q: Is this possible? The valve is way too big to fit the rim. Is there a special inner tube for this rim? Thanks in advance.

- Sounds as if you need a tube with a Presta valve stem vs. a Schrader valve stem. Link below showing the difference.

- Q: I had a doctor who was suspicious of me having a heart valve problem. I don't want to be on medication for the rest of my life. I only want to change my diet, pray, exercise, and meditate. I don't believe the doctor has that cure for that problem that's if it was a heart valve problem.

- It depends on what sort of heart valve problem you have, how bad it is, and how bad the symptoms are. Sometimes you don't need to do anything special except watch the diet and lifestyle, sometimes you need medicine, and sometimes the cure is surgical repair or replacement of the valve. I think prayer is a fine thing to help, but the Lord also gave us the skills so doctors could provide something a little more physical. If your heart valve problem is bad enough, it can cause damage to your heart and the rest of your body that all the prayer, diet, exercise and meditation in the world won't help fix. However, as a patient, it's always your decision if you want to take the doctor's advice or not. Otherwise you could find yourself dead, and explaining to God why you chose not to take the help He provided for you. So before you go making any decisions, you need to wait until you find out what the entire story is. Then weigh up all your options carefully,and decide.

- Q: My question mainly pertains to Electric Motor-driven Motor Operated Valve Actuators.

- The motor drives a gear operator on the valve and is limited in the degree to which it operates by a set of limit switches so it doesn't over run or over torqued the shaft. This arrangement typically also has another set of limit switches that indicate the open or closed position so the person controlling the valve will know its position. This type of operator is typically used on ball, butterfly or plug valves but can be used on gate valves.

- Q: I was diagnosed with Mitral Valve prolapse...I'm 21, 5.5 tall and 130lbs, I had a healthy lifestyle...my doctor said that my case isn't really sever..but i'm taking medications to keep it this way...something i cannot ask my doctor about, would intercourse be harmful to me? and how should I deal with it??? is it okay for me to have children in the future? and could my MVP be cured without surgery??

- good blood does not mix with bad blood. The values have nothing to do with that as the two sides of the heart are separate. With Mitral valve incompetence or prolapse, the valve does not close like it is suppose to. That allows back flow of blood. If bad enough, the treatment is a valve replacement. With Mitral valve stenosis, the valve does not open like it is suppose to. That prevents flow through the valve. The treatment is a valve replacement or sometimes a simple cut in the valve to relieve the stenosis can be done. Either way, if bad enough, surgery is needed, not pills.

- Q: hi guys..What is different between globe valve and stop check globe? Is that stop check globe=SDNR JIS std?

- I am not even sure what you are talking about. a globe valve is a type of valve that can stop the flow by turn a handel on top of the valve. A check valve on let the flow go one way and stops the flow the other way. hope this help Globe valve From Wikipedia, the free encyclopedia Jump to: navigation, search A Globe valve is a device (specifically a type of valve) for regulating flow in a pipeline, consisting of a movable disk-type element and a stationary ring seat in a generally spherical body.[1] Globe Valves are named for their spherical body shape with the two halves of the body being separated by an internal baffle. This has an opening that forms a seat onto which a movable plug[2] can be screwed in to close (or shut) the valve. The plug is also called a disc or disk.[3][4][5] In globe valves, the plug is connected to a stem which is operated by screw action in manual valves. Typically, automated valves use sliding stems. Automated globe valves have a smooth stem rather than threaded and are opened and closed by an actuator assembly. When a globe valve is manually operated, the stem is turned by a handwheel. Although globe valves in the past had the spherical bodies which gave them their name, many modern globe valves do not have much of a spherical shape. However, the term globe valve is still often used for valves that have such an internal mechanism. In plumbing, valves with such a mechanism are also often called stop valves since they don't have the global appearance, but the term stop valve may refer to valves which are used to stop flow even when they have other mechanisms or designs. Globe valves are used for applications requiring throttling and frequent operation. For example, globe valves or valves with a similar mechanism may be used as sampling valves, which are normally shut except when liquid samples are being taken. Since the baffle restricts flow, they're not recommended where full, unobstructed flow is required.

- Q: I have a lawn tractor with a 10 hp Tecumseh and its running so rich because of the carburetor float valve not seating. So how should I fix this?

- www.okorder

- Q: My 3rd valve keeps getting stuck when i play it, i have valve oil, but its just not working, help please

- There are several possibilities. You may have buildup on either the valve or the casing. Cleaning it thoroughly should normally remove it, but every once in a Blue Moon it pays to take it in and have it professionally cleaned. They can inspect it at the same time and tell you if you have a bend or a ding in the casing. Sometimes they are really hard to spot, especially if they are hidden in one of the crevices of the detail work. A really good repair person can stick a scope down there and tell you if you have some kind of blockage in just a few minutes. The only way to really clean inside the casing yourself is to get a good bottle brush that fits inside with just a little bit of resistance. You should really get someone to show you how to do it the first time because you don't want to go scraping up the insides. There is one other possibility that is kind of rare. Sometimes you get some gunk up under the valve button and it sticks when you push it down. You should normally be able to see this just by looking underneath however. Best of luck and I hope you find your sticking point and are able to set it free.

- Q: We had a sprinkler zone that did not send much water to sprinkler heads. Checked the spring on the solenoid. We took off the top of the valve and rinsed gasket and parts below – put back together. The zone then worked. However I then noticed that the valve that does not shut off completely – water meter shows usage. I turn off water as it comes from the house.We then replaced the solenoid, the zone would not turn on. When back to the old solenoid. I switched wires at the timer and valve, it started, but when the cycle was through there still was water going through the system. Put wires back to their original locations.Space is crowded and looks tricky to replace valve. Would like advice on that for next year. However my main concern is when we shut down for the winter. We manually run each of the 8 stations and blow out the water. Will the bad valve cause a problem?

- If there's water going through the valve when it's in the off state, the valve seat or seal must be worn or damaged. If it's the valve seat, you'll likely have to replace the valve. When you say manually run each [station] and blow out the water, are you using compressed air? Otherwise, it's not clear how running water would blow out the water. In any case, if the valve in question opens, it should allow for your blowing out process, and if the water is shut off completely at the valve, no water should get in to refill the pipes.

Send your message to us

Ball Valve For Heating Supply PN 4 Mpa high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords