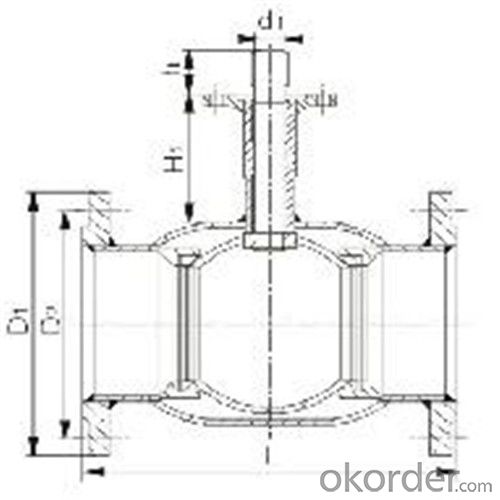

Ball Valve For Heating Supply PN 2.5 Mpa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ball Valve For Heating Supply

Product Description of Ball valve for heating supply:

Technical introduction

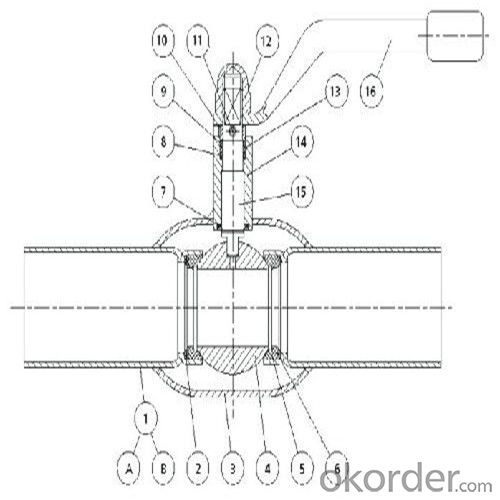

★The ball valve is designed as fully welded structure,which can prevent the leakage of medium.

★The valve seat is floating and spring-loade.The seal is made of soft seal materials of PTFE+20%C and Viton B.The seat is tightly abutted against the ball surface by the pressure of a spring,so that even if the media is in low pressure,a reliable sealing can be assured for the ball valve.Double piston effect and double seal(two-seal seat)are adopted in specially designed valve seat to realize double sealing,which makes the tightness of the ball valve more advantageous and the operation easier.

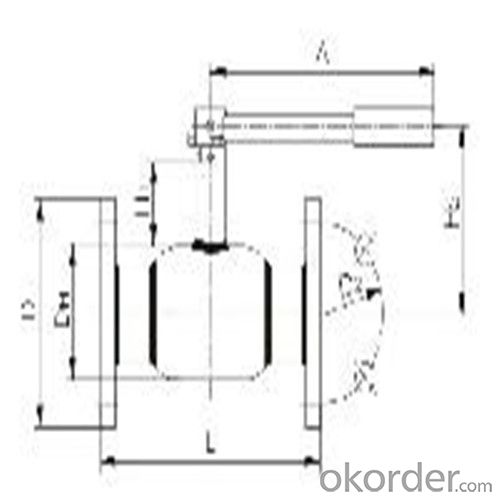

★A floating ball is adopted for DN15-DN200,and a stem and trunnion ball is adopted for DN200 and above,which can ensure the accurate position of different size ball.In other words,the sealing performance,low torque valve and operability can be guaranteed.

★The sealing of the stem is fulfilled by two replaceable O-rings and packing consisting of PTEE+20%C or flexible graphite,as the packing seal material,is fire proof effect,and is specially suitable for fuel gas systems.

★The materials used for the valve body and pipelines are the same(carbon steel or SS steel),valve body and stem adopt SS steel and the packing adopts PTEE+20%C which is corrosion-resistance or flexible graphite.

Design Features of Ball valve for heating supply:

Features and Applications

Raymond's fully welded ball valve for heating supplyand Fuel Gas systemare used to control the flow at fully open or closed position,not regulate the flow.Only special types of ball valves can realize the flow regulation.Therefore,our welded ball valves can satisfy the requirements of heating systems,e.g:

★Main pipelines of heating equipment

★Cross channels of heating pipes

★Heat exchanger station and any long distance operating station,e.g:

For the transmission of hot water and two kinds of mixed media(water,air or natural gas),limited to Max.4.0MPa and 200°C.

For the transmission of natural gas and one medium,from -30°C to 60°C,and even up to 150°C using specially designed ball valves.

★Coal gas pipelines,trunk and the branch supply lines.

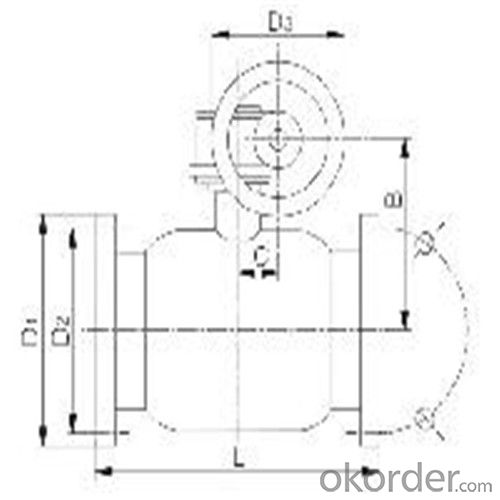

Standard of Ball valve for heating supply:

Actuator | Gear Handwheel customize |

Connection | Flange SW Weld customize |

Medium | Gas Natural gas Water customize |

Medium Temperature | <200< span="">℃ customize |

Application Fields | Electricity Medical Petrochemical customize |

Connection Standard | EN 1092-1 EN 12627 ISO 7-1 customize |

FAQ of Ball valve for heating supply:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: Among butterfly,ball,needle and gate valves which is used mostly in pneumatic system?

- I don't agree that gate valves operate quickly and that they usually don't leak. Gate valves are slow to operate specially in large sizes and they all tend to leak unless they have a soft seat and there are very few of these type of gate valves. In larger piping systems globe valves are used to throttle air but not usually as a on/off valve. Probably the best on/off valve is the soft seated ball valve. They work well regardless of size with very little if any leakage. You can get some butterfly valves with soft seats that are really designed to operate much like a ball valve but are only economic in large sizes. The disc in these valves is essentially a wafer out of the sphere and that is why they do so well.

- Q: Is it supposed to go on or only in cases when the power goes out??? I bought this pump and the directions are horrible!!! There isn't room for both the air stone and the check valve!! How does this stupid thing work???

- Check valve designated that it lets air go in one direction and stops water from going in reverse direction. For example if your airline gets disconnected from airpump by accident and drops on floor water won't gets syphoned out frmo tank to floor. You'd be surprised how much water can end up on floor in this scenario ;-) In order to install check valve you have to cut airline somewhat in halfs and put your checkvalve between pump and airstone. Arrow shows direction in which it passes air.

- Q: The shutoff valve for the hot water under my bathroom sink has a very tiny leak. It is coming from where the turn knob meets the valve.So long as the valve is either all the way open or all the way closed, all I get is a single drop every couple seconds. But if it is anywhere in-between, it is a pretty steady drip.What's the simple/quick fix for this? Replacing the entire shutoff valve is probably not an option because it is an apartment complex.

- The packing around the compression nut where the valve stem enters the valve body needs a twist or two clockwise. Take a small crescent adjustable wrench, and tighten this nut to the right. Should stop the leak. If not, you may have to replace valve but usually this simple fix works. NOTE: If you tighten it to much, you won't be able to open or close the valve, so use just enough effort to stop the leak without needing the incredible hulk to budge the valve.

- Q: I have a 1997 ford aerostar and my mechanic just called me and said that the pop off valve needs to be replaced, but it is attached to the line so the hole line has to be replaced to. I want to try to find the pop off valve to see if I can get it b/c he can't find the replacement part, what I need to know is what it looks like. or where it is on an aerostar, because I have 5 more sitting in the driveway and I can look for it.

- Well, for AC, you can have the old school R12, that looks like a tire valve. New school is high and low side R134. These 134 ports are usually located on the fitting that is crimped to the hose. A new hose would be the only option. If you have the old R12 style, they sell an adapter for $5 that will convert it to a 134 high side.

- Q: I go deer hunting with my dad and he has an artificial heart valve. It isn't too loud, but I can hear it about ten feet away if it's quiet enough. Is it possible that we haven't shot any deer yet because the deer can hear the valve and know to stay away?

- Wow, you must have really good ears. My friend has 2 heart valves which are ball and socket type and they click really loud, but I can only hear them with a stethescope. I doubt deer can connect that click with a human.

- Q: Hi, I am a junior in high school and I play the trumpet. For the past week or so my 1st valve has been odd. It gets stuck badly when it hits all the way to the bottom, and I can't seem to get it to stop. Normally when valves are sticky I just use some valve oil and it helps a lot. But it doesn't seem to work this time. It is a Bach if that helps. I think there are other types of valves so I'll say that there is a spring inside from like the middle to top. If you could help me out that would be great! Thanks =)

- Depending on where you live in the world, humidity can cause your valves to seize. I was playing a gig in Washington, DC this summer with the US Army Band Pershing's Own and one of our horn players' rotors seized, and one of the trumpet player's valves seized too - being from Ottawa, Canada, the humidity in DC was a huge change! Also, if your top valve caps are too tight, it can cause the reaction of the valves to seem like they're locking. This happened to the 4th valve on my piccolo trumpet. Another issue to consider is the gap between your piston and the outer casing. The smaller the gap, you need an oil with less viscosity. The larger the gap, an oil with higher viscosity often works better. After owning a few different horns, I've learned which oils work better for each brand of trumpet. Just some food for thought!

- Q: Ok, so I was just wondering, do you have to have a turbo to get blow-off valves? Also, do you have to have a manual? And are there any other requirements?

- I'm a girl.....you don't have to have a turbo, any type of fast car will get you blown off.

- Q: are the carborator reed valves supposed to be open or closed on a 1999 yz 250?dirt bike

- reed valves depend on engine vacuum to operate. the reed valves are closed when the engine is off and as the engine load goes up, it requires more fuel so engine vacuum goes up causing the reed valves to open more, letting in more fuel. So, is the engine running or off?. are the reeds bent? if they are, they might be straightened if u use care. they break ez.

- Q: I have a 03 civic ex with 96k how important is it that I do a valve adjustment. The engine runs smooth.

- Honda valves don't NEED adjustment unless you have serious problems.. If you give it the correct gas...keep the oil changed and don't beat on the engine, it won't need LOTS of work...

- Q: I was diagnosed with Mitral Valve Prolapse. Does anyone else have this? Does this cause panic attacks? I have heard that. What other problems does it cause?

- What is mitral valve prolapse? How does a patient with MVP feel? How is mitral valve prolapse diagnosed and evaluated? What is the treatment for MVP? Mitral Valve Prolapse At A Glance What is mitral valve prolapse? Mitral valve prolapse (also known as click murmur syndrome and Barlow's syndrome) is the most common heart valve abnormality, affecting five to ten percent of the world population. A normal mitral valve consists of two thin leaflets, located between the left atrium and the left ventricle of the heart. Mitral valve leaflets, shaped like parachutes, are attached to the inner wall of the left ventricle by a series of strings called chordae. When the ventricles contract, the mitral valve leaflets close snugly, preventing backflow of blood from the left ventricle into the left atrium. When the ventricles relax, the valves open to allow oxygenated blood from the lungs to fill the left ventricle. In patients with mitral valve prolapse, the mitral apparatus (valve leaflets and chordae) becomes affected by a process called myxomatous degeneration. In myxomatous degeneration, the structural protein, collagen, forms abnormally and causes thickening, enlargement and redundancy of the leaflets and chordae. When the ventricles contract, the redundant leaflets prolapse (flop backwards) into the left atrium, sometimes allowing leakage of blood through the valve opening (mitral regurgitation). When severe, mitral regurgitation can lead to heart failure and abnormal heart rhythms. Most patients are totally unaware of the prolapsing of the mitral valve. Others may experience a number of symptoms discussed below. The mitral valve prolapse (MVP) syndrome has a strong hereditary tendency, although the exact cause is unknown. Affected family members are often tall, thin, with long arms and fingers, and straight backs. It is seen most commonly in women from 20 to 40 years old, but also occurs in men.

Send your message to us

Ball Valve For Heating Supply PN 2.5 Mpa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords