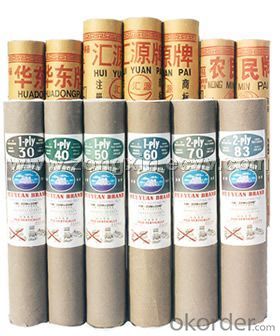

ASTM standard roofing felt synthetic underlament for use under shingles,tile,metal or slate

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Asphalt Roofing Felt

Description

| Width | length | Weight | Thickness | Usage |

ASTM D-226 roofing felt 30# | 36in 0.914m | 72ft 21.95 m | 23.5kg

| 1.2mm | A roofing felt used as an underlay beneath asphalt shingles, wood shakes, tiles and other sloped coverings.

|

ASTM D-226 roofing felt 15# | 36in 0.914 m | 144ft 43.89 m | 23kg | 0.8mm | |

ASTM D-4869 roofing felt 15# | 36in 0.914m | 144ft 43.89m | 16.5kg | 0.6mm | |

ASTM D-4869 roofing felt 30# | 36in 0.914m | 72ft 21.95m | 13.5kg | 0.8mm |

Description:

A heavy-weight asphalt roofing felt made of a specially formulated organic sheet which has been fully saturated with waterproofing asphalt.

Uses:

A roofing felt used as an underlay beneath asphalt shingles, wood shakes, tiles and other sloped coverings.

Physical Specificatons:

Average roll weight,Lbs/roll:54lbs

Packaging:

Width:36''(0.914m)

Roll Contents:216 sq.ft(20sq.m)

Rolls per pallet:30

Pallet size:1.1mx1.1m

asphalt roofing felt (Black building paper )

Product description

Black building paper is a heavy-weight asphalt roofing felt made of a specially formulated organic sheet which has been fully saturated with waterproofing asphalt.

Product characteristic

1 asphalt waterproof roof underlay felt

2 good at water-resistence, anti-aging

3 eco-friendly roof felt

4 ASTM D-4869I II; ASTM D-226I II

Applicable scope

Widely used as an underlay beneath asphalt shingles, wood shakes, tiles and other sloped coverings.

specifications performance

Test item | ASTM D-226 15# | ASTM D-226 30# | ASTM D-4869 15# | ASTM D-4689 30# |

Pliability at 23±2°C.tested shall not crack when bent 90° at a uniform speed over a rounded corner of radius in table for each | 12.7mm (radius) | 12.7mm (radius) | 12.7mm (radius) | 12.7mm (radius) |

Tear strength at 23±2°C min | 2.5N | 2.5N | 2.5N | 2.5N |

Breaking strength at 23±2°C min MD | 30LBF/in | 40lbf/in | 30lbf/in | 40lbf/in |

Breaking strength at 23±2°C min CD | 15lbf/in | 20lbf/in | 15lbf/in | 20lbf/in |

Loss on heating at 105°Cfor 5h max | 4.0% | 4.0% | 6.0% | 6.0% |

Width of the roll | 36 in | 36 in | 36 in | 36 in |

Area of the roll | 432 ft2 | 216 ft2 | 216 ft2 | 216 ft2 |

Net mass of saturated felt,min | 560 g/m2 | 1270g/m2 | 400g/m2 | 660g/m2 |

Saturation,%by wt., min | 120% | 150% | 100% | 120% |

Asphalt Roofing Felt

Description

| Width | length | Weight | Thickness | Usage |

ASTM D-226 roofing felt 30# | 36in 0.914m | 72ft 21.95 m | 23.5kg

| 1.2mm | A roofing felt used as an underlay beneath asphalt shingles, wood shakes, tiles and other sloped coverings.

|

ASTM D-226 roofing felt 15# | 36in 0.914 m | 144ft 43.89 m | 23kg | 0.8mm | |

ASTM D-4869 roofing felt 15# | 36in 0.914m | 144ft 43.89m | 16.5kg | 0.6mm | |

ASTM D-4869 roofing felt 30# | 36in 0.914m | 72ft 21.95m | 13.5kg | 0.8mm |

Description:

A heavy-weight asphalt roofing felt made of a specially formulated organic sheet which has been fully saturated with waterproofing asphalt.

Uses:

A roofing felt used as an underlay beneath asphalt shingles, wood shakes, tiles and other sloped coverings.

Physical Specificatons:

Average roll weight,Lbs/roll:54lbs

Packaging:

Width:36''(0.914m)

Roll Contents:216 sq.ft(20sq.m)

Rolls per pallet:30

Pallet size:1.1mx1.1m

asphalt roofing felt (Black building paper )

Product description

Black building paper is a heavy-weight asphalt roofing felt made of a specially formulated organic sheet which has been fully saturated with waterproofing asphalt.

Product characteristic

1 asphalt waterproof roof underlay felt

2 good at water-resistence, anti-aging

3 eco-friendly roof felt

4 ASTM D-4869I II; ASTM D-226I II

Applicable scope

Widely used as an underlay beneath asphalt shingles, wood shakes, tiles and other sloped coverings.

specifications performance

Test item | ASTM D-226 15# | ASTM D-226 30# | ASTM D-4869 15# | ASTM D-4689 30# |

Pliability at 23±2°C.tested shall not crack when bent 90° at a uniform speed over a rounded corner of radius in table for each | 12.7mm (radius) | 12.7mm (radius) | 12.7mm (radius) | 12.7mm (radius) |

Tear strength at 23±2°C min | 2.5N | 2.5N | 2.5N | 2.5N |

Breaking strength at 23±2°C min MD | 30LBF/in | 40lbf/in | 30lbf/in | 40lbf/in |

Breaking strength at 23±2°C min CD | 15lbf/in | 20lbf/in | 15lbf/in | 20lbf/in |

Loss on heating at 105°Cfor 5h max | 4.0% | 4.0% | 6.0% | 6.0% |

Width of the roll | 36 in | 36 in | 36 in | 36 in |

Area of the roll | 432 ft2 | 216 ft2 | 216 ft2 | 216 ft2 |

Net mass of saturated felt,min | 560 g/m2 | 1270g/m2 | 400g/m2 | 660g/m2 |

Saturation,%by wt., min | 120% | 150% | 100% | 120% |

- Q: Do you need a cushion on the ground floor?

- As well as the time to build a wooden building with concrete pier, from the ground or contact the ground to do a good job preserving.

- Q: Roof waterproof mattress should play the number of centimeters appropriate

- Roof waterproofing can not use a single waterproof material, must be rigid and flexible combination of construction, flexible waterproof stretch is good, a little bit of settlement or deformation will not damage the waterproof layer. Rigid waterproof (ie mortar waterproofing agent) waterproof at the same time, can play a protective role, waterproof layer is not easy to be destroyed.

- Q: When the cushion is used, the thickness of the protective layer is not less than ()

- Master roof: the general use of 40 thick C20 reinforced fine stone concrete protection.

- Q: The roof cushion is waterproof on the slope roof

- and the formation of the ice dam will lead to roof water, water will find the path into the house.

- Q: Is it possible to make a waterproof layer

- 2, waterproof layer: In order to prevent the rain into the roof, groundwater into the wall, basement and underground structures, indoor water into the floor and walls and other materials layer.

- Q: Is the raft cushion waterproofing full of the cushion?

- As for the bottom of the bar thickness of the protective layer is generally 4cm, but if the basic floor of the concrete label is relatively high, the protective layer can be appropriately reduced.

- Q: Can the floor tiles be removed from the cement mats on the prefabricated board floor?

- Prefabricated board surface is best to do some cement mortar cushion, can prevent the decoration of the water generated to the downstairs.

- Q: Cushion, waterproof layer construction to do what information

- 1, the cushion to do template inspection batch information. Waterproof to do waterproof shelter, waterproof inspection batch, waterproof detail structure.

- Q: What is the relationship between the cushion and the ring beam?

- Cushion is plain concrete or asphalt concrete (for groundwater soil corrosive strong site). Is located below the ground, in order to prevent the foundation or the concrete beam pouring when the excessive loss of water caused by defects set. The purpose is to ensure the quality of concrete, increase the durability of underground components

- Q: Why calculate the amount of time to count a lot of cushion ah

- It can be seen, in the preparation of the project budget, the cushion is also a very important sub-head, the amount of its calculation is often measured by m3, the current commonly used materials are concrete, gravel, stone, Stone slag), slag, slag concrete, lime and so on.

Send your message to us

ASTM standard roofing felt synthetic underlament for use under shingles,tile,metal or slate

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords