ASTM 316L Embossing Stainless Steel Sheet / Stainless Steel Sheet Embossed

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

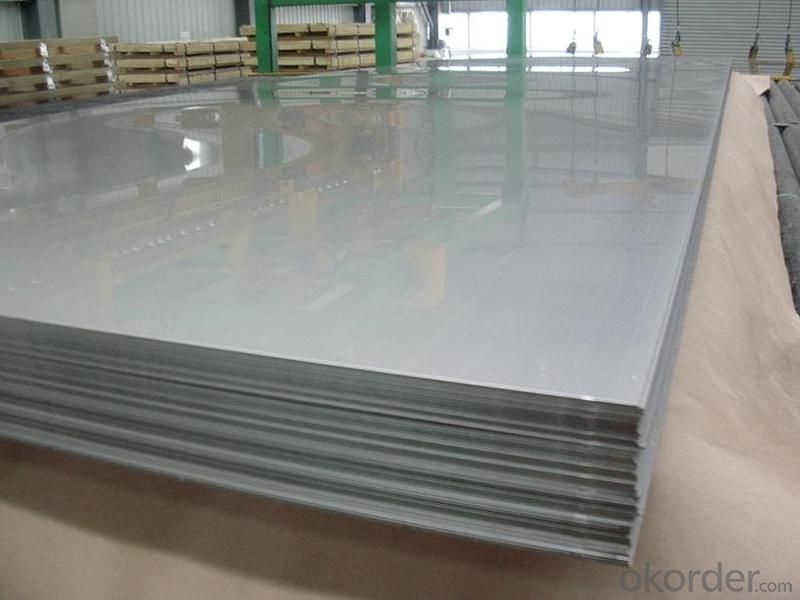

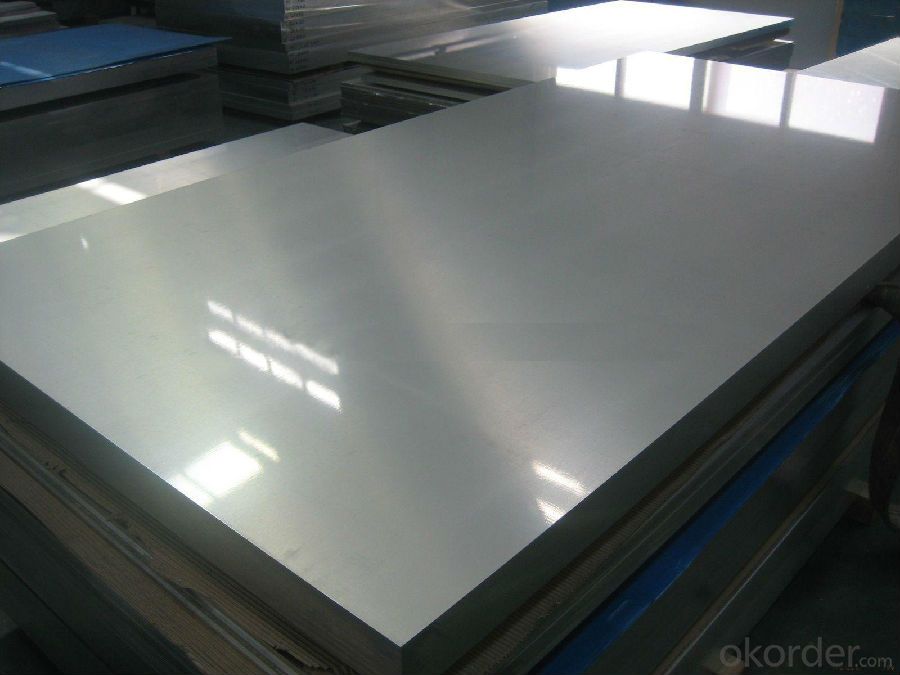

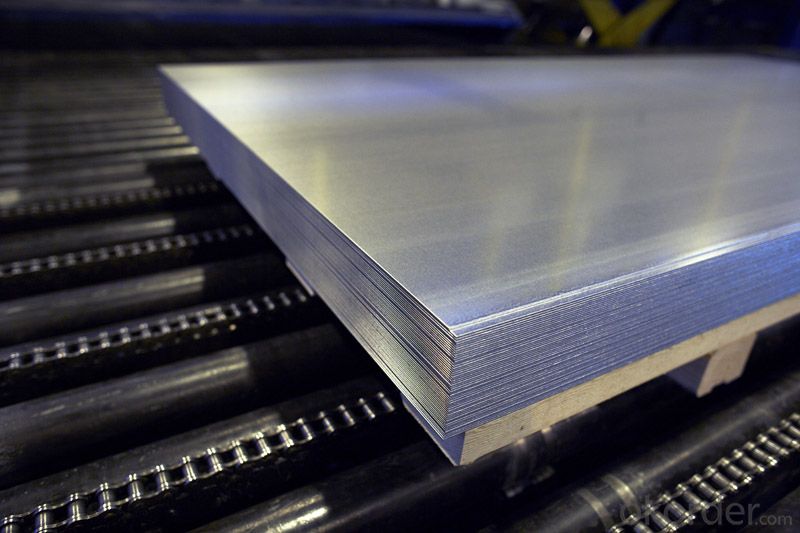

ASTM 316L Embossing Stainless Steel Sheet / Stainless Steel Sheet Embossed

Packaging Details:Wooden pallets,water proof paper-20'GP or 40'GP for stainless steel sheet.

Delivery Detail:within 5-7 days after receiving the deposit

1. Specifications about stainless steel sheet

Commodity | Professional 430 201 202 304 304l 316 316l 321 310s 309s 904l stainless steel sheet |

Grade | 201,202,304,304L,316,316L,310S,309S,321,301,310,410,420,430,904L |

Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

Certification | SGS,BV,IQI,TUV,ISO,etc |

Thickness | 0.2mm-150mm |

Width | 1000,1219,1250,1500mm, or as your requirements |

Length | 2000,2438,2500,3000,6000mm, or as your requirements |

Surface | No.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film. |

Standard | ASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc |

Delivery time | 5-7 days after confirming the order |

MOQ | 1 Ton |

Advantages | Showing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste. |

2.Production Flow about stainless steel sheet

Raw materials are sending to hot rolling units for rolling into different sizes

Hot rolled material is annealing in cold; rolled annealing furnace and pickling in acid.

All mill rolls are grinded on precision grinding machine with proper chamfering after first shiftoperation.

All sheets are pickled in different tanks and dried on brush roll machine before dispatched.

These sheets are again annealing and are sent to straighten machine for straightening.

Inspections are done at various stages. Keep proper control overall internal process via rolling,annealin and pickling by our experienced staff.

3.Surface--stainless steel sheet

| Surface Finish | Definition | Application |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA/8K mirror | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| Hairline | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

- Q: Can stainless steel sheets be used for sink fabrication?

- Certainly, sink fabrication can make use of stainless steel sheets. Undeniably, stainless steel stands as a favored material for sinks owing to its strength, ability to resist corrosion, and appealing appearance. By easily molding and joining stainless steel sheets, a sink design without visible seams can be effortlessly achieved, thanks to their pliability and adaptability to specific measurements and styles. Moreover, stainless steel boasts hygienic properties and simple maintenance, rendering it a sensible option for kitchen and bathroom sinks.

- Q: 304 how can the water stain on the surface of stainless steel plate be formed?

- If you want to scrub the proposal as soon as possible processing, water Jiyue long more difficult to wear off, if it is ferrite, also easy to rust.

- Q: Are stainless steel sheets suitable for food processing?

- Yes, stainless steel sheets are highly suitable for food processing. Stainless steel is a strong and durable material that is resistant to corrosion, heat, and chemical damage. It is non-reactive with food, which ensures that it will not affect the taste or quality of the processed food. Additionally, stainless steel is easy to clean and maintain, making it a hygienic choice for food processing environments.

- Q: What's the price of 06cr19ni10 and 304 stainless steel?

- The term "304 stainless steel" comes from the United states. Many people think that "304 stainless steel" is a type of Japanese name, but in strict sense, Japan's 304 stainless steel formal name is "SUS304"". The common marking methods in the market are 06Cr19Ni10304, SUS304, three kinds, in which 06Cr19Ni10 generally means GB standard production, and 304 generally means ASTM standard production, SUS304 mark day standard production.

- Q: What stainless steel can be used instead of galvanized sheet?

- 201 stainless steel is one of the 200 series stainless steel. 200 series stainless steel is low nickel high manganese stainless steel, nickel content is generally below 4%, manganese content of about 8%, is a nickel type stainless steel. 201 stainless steel is widely used in building decoration, municipal engineering, highway guardrail, hotel facilities, shopping malls, glass handrails, public facilities and other places. The equipment high precision automatic pipe, through its dissolve welding, roll forming, without any metal filler, filling gas protection (inside and outside of the pipe side) welding, welding process for TIG, and on-line solution of eddy current testing.

- Q: How do you join stainless steel sheets together?

- Stainless steel sheets can be joined together through various methods, such as welding, riveting, bolting, or using adhesives. The specific joining technique depends on the application, the desired strength, and the aesthetic requirements.

- Q: What are the bending limits of stainless steel sheets?

- The bending limits of stainless steel sheets depend on several factors such as the grade of stainless steel, thickness of the sheet, and the specific type of bending process being used. Stainless steel sheets are known for their excellent strength and durability, which allows them to be bent to a certain extent without breaking or cracking. In general, stainless steel sheets can be bent to a radius that is at least twice the thickness of the sheet. For example, if the sheet is 1mm thick, it can typically be bent to a minimum radius of 2mm. However, it is important to note that this is just a general guideline and the actual bending limits may vary depending on the specific grade of stainless steel. Certain grades of stainless steel, such as 304 and 316, have higher yield strengths and are more resistant to deformation, making them suitable for more severe bending applications. Thicker sheets also have higher bending limits compared to thinner ones, as they have more material to withstand the bending forces. It is also worth mentioning that the type of bending process used can affect the bending limits of stainless steel sheets. Processes like press brake bending and roll bending are commonly used for bending stainless steel sheets. These processes utilize different techniques and equipment, which can result in varying bending limits. To determine the exact bending limits for a specific grade and thickness of stainless steel sheet, it is best to consult the manufacturer's specifications or seek guidance from a professional metal fabricator. They can provide accurate information and guidance on the bending capabilities of stainless steel sheets for your specific application.

- Q: Can stainless steel sheets be used for kitchen appliances?

- Yes, stainless steel sheets can be used for kitchen appliances. Stainless steel is a popular material choice for kitchen appliances due to its durability, resistance to corrosion, and easy maintenance. It is commonly used for making ovens, refrigerators, dishwashers, and other kitchen appliances. Stainless steel sheets are versatile and can be easily formed into various shapes and sizes to fit different appliance designs. Additionally, stainless steel has a sleek and modern appearance, making it a preferred choice for many homeowners and chefs.

- Q: What's the difference between 201 and 204 stainless steel plates? Thank you

- Price, 04 is far higher than the price of 01, according to the use of the environment, product quality requirements to choose the right material

- Q: Are stainless steel sheets suitable for architectural mesh applications?

- Yes, stainless steel sheets are highly suitable for architectural mesh applications. Stainless steel is a versatile and durable material that offers numerous benefits for architectural applications. It is resistant to corrosion, which is crucial for long-term performance in outdoor and high-moisture environments. Additionally, stainless steel has excellent strength and can withstand heavy loads, making it ideal for structural applications. Architectural mesh made from stainless steel sheets offers a unique combination of functionality and aesthetics. It can be used for a wide range of applications, including facades, cladding, sunshades, balustrades, and partitions. The mesh can be woven or welded into various patterns and shapes, allowing for creative and visually appealing designs. Stainless steel architectural mesh also provides excellent transparency and airflow, making it suitable for applications that require ventilation or light transmission. It can enhance the aesthetics of a building by creating a sense of openness while providing privacy and security. Moreover, stainless steel offers a high degree of customization. It can be finished in different colors and surface textures, allowing architects and designers to achieve their desired look and feel. Additionally, stainless steel is a sustainable material as it is fully recyclable and has a long lifespan, reducing the environmental impact of architectural projects. In conclusion, stainless steel sheets are highly suitable for architectural mesh applications due to their corrosion resistance, strength, versatility, and aesthetic appeal. They provide architects and designers with a wide range of options to create visually striking and functional structures.

Send your message to us

ASTM 316L Embossing Stainless Steel Sheet / Stainless Steel Sheet Embossed

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords