API Standard Oil and Gas Well Casing Tube K55

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

casing pipe for oilfield

API 5CT Q125 Casing Pipe|Olifield Casing Pipe

roduct: API 5CT oil casing pipe

Grade: Q125-1,Q125-2,Q125-3,Q125-4.

H40.J55.K55.N80.C75.L80.C90.T95.P110.

OD: 114.3mm to 508mm

Wall thickness: 5.12mm to 16.13mm

Length: R1(4.86-7.62M). R2(7.62-10.36M). R3(10.36-13Meters)

Thread: STC.BTC.LTC

Standard: API 5CT

Technical: Hot Rolled

Type: Seamless alloy API pipe

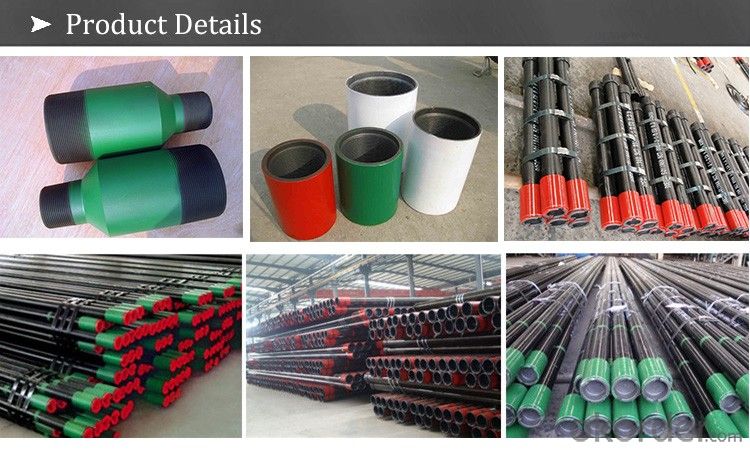

Surface treatment: blank oil painting+green/red/white/brown painting

Packing: Coating and steel thread protector,3tons in a bundle packed by steel strip

Third party inspection: BV|SGS|TUV

Usage: oil pipeline, oil natural gas, industrial gas, water transportation

Certificate:

API 5CT,Russian Certificate,ISO,CCS

Inspection

Physical properties are checked and each length hydrostatically tested, normally to only 3,000 psi in the plain end (unthreaded) condition. The following are also checked:

Dimensions

Weights

Straightness

Lengths

Part of this inspection is to drift all lengths.

Despite all the American Petroleum Institute (API) specifications and testing, some tubing defects are still found after delivery; thus, some operators do further inspection.

Inspection Method

Size and surface inspection

NDT and pressure test and third party certication

Hydrostatic

Drifting test

Physical and chemicail analysis

Hardness and pressure test.

Electromagnetic

Magnetic particle

Ultrasonic

Out Diameter weight Grade Thread Length in mm kg/m lb/ft 4-1/2" 114.3 14.14-22.47 9.5-15.10 Q125-1,Q125-2,Q125-3,Q125-4 STC/LTC/BTC/XC R1/R2/R3 5" 127 17.11-35.86 11.5-24.10 Q125-1,Q125-2,Q125-3,Q125-4 STC/LTC/BTC/XC R1/R2/R3 5-1/2" 139.7 20.83-61.14 14-22.22 Q125-1,Q125-2,Q125-3,Q125-4 STC/LTC/BTC/XC R1/R2/R3 6 5/8" 168.28 29.76-47.62 20-32 Q125-1,Q125-2,Q125-3,Q125-4 STC/LTC/BTC/XC R1/R2/R3 7" 177.8 25.3-84.97 17.00-57.10 Q125-1,Q125-2,Q125-3,Q125-4 STC/LTC/BTC/XC R1/R2/R3 7-5/8" 193.68 35.72-82.3 24.00-55.30 Q125-1,Q125-2,Q125-3,Q125-4 STC/LTC/BTC/XC R1/R2/R3 8-5/8" 219.08 35.72-72.92 24.00-49.00 Q125-1,Q125-2,Q125-3,Q125-4 STC/LTC/BTC/XC R1/R2/R3 9-5/8" 244.48 48-112.50 32.30-75.62 Q125-1,Q125-2,Q125-3,Q125-4 STC/LTC/BTC/XC R1/R2/R3 10-3/4" 273.05 48-127 32.75-85.30 Q125-1,Q125-2,Q125-3,Q125-4 STC/LTC/BTC/XC R1/R2/R3 11-3/4" 298.45 62.50-105 42.00-71.00 Q125-1,Q125-2,Q125-3,Q125-4 STC/LTC/BTC/XC R1/R2/R3 13-3/4" 339.72 71.43-107.15 48.00-72.00 Q125-1,Q125-2,Q125-3,Q125-4 STC/LTC/BTC/XC R1/R2/R3 16" 406.40 96.73-162.21 65.00-109.0 Q125-1,Q125-2,Q125-3,Q125-4 STC/LTC/BTC/XC R1/R2/R3 18-5/8" 473.08 130.21 87.50 Q125-1,Q125-2,Q125-3,Q125-4 STC/LTC/BTC/XC R1/R2/R3 20" 508.00 139.89-197.9 94.00-133.00 Q125-1,Q125-2,Q125-3,Q125-4 STC/LTC/BTC/XC R1/R2/R3 Remarks: 1 R1: 4.86M-7.62M R2: 7.62M-1036M R3:10.36M-12M 2 Standard: API 5CT 3 Grade: H40/J55/K55/N80/C75/L80/C90/T95/P110/Q125 Our service:

1): Durable, strict quality management and control, production follow the ISO.

2): Advanced precision casing pipe equipment to guarantee prime quality.

3): Casing pipe with smooth surface. No defects. Continuous skill improvements.

4): Short delivery, competitive good offer. Casing pipe MOQ is low.

5): Third party Inspection for casing pipe can be TUV/SGS/BV6): Company design team always think how develop new skill and new products to meet requirements of markets.

7): Good service, IF customers have any problem during application, we will surely try our best to solve them.

8): Regular thread is STC/LTC/BTC or as client's requirement.9): Surface treatment can be painted, or based on the requirements of customers.

- Q: What are the different types of supports used for aboveground steel pipes?

- There are several types of supports commonly used for aboveground steel pipes, including pipe hangers, pipe clamps, pipe saddles, and pipe shoes. These supports are designed to provide stability and prevent excessive movement or vibration of the pipes, ensuring their proper alignment and preventing damage.

- Q: How are steel pipes measured and specified?

- Steel pipes are measured and specified based on their diameter (nominal pipe size or NPS) and wall thickness (schedule or SCH). The NPS represents the internal diameter of the pipe, while the SCH indicates the thickness of the pipe walls. These measurements are crucial for ensuring proper compatibility and functionality in various applications, such as plumbing, construction, and industrial processes.

- Q: Seamless steel tube DN15 specification phi 18*3 what do you mean?

- Seamless steel pipe DN15 specification phi 18*3 refers to 3 outer diameter of 18mm B type DN15 seamless steel tube.

- Q: Are steel pipes suitable for underground sewage lines?

- Yes, steel pipes are suitable for underground sewage lines. They are strong, durable, and resistant to corrosion, making them an excellent choice for sewage systems.

- Q: What steel pipes are buried for outdoor heating pipes? Seamless or welded tube? Are there any rules for specific countries? Can use the seamed tube?

- Where outdoor heating pipes are buried, what steel pipe shall be referenced by the 11.1.2 code for installation of outdoor piping?:This chapter applies to the quality inspection and acceptance of the outdoor heating pipe network installation of the plant and the civil building group (residential area) with the saturation steam pressure not greater than 0.7MPa, and the hot water temperature not exceeding 130 degrees celsius.

- Q: How are steel pipes used in the construction of hydroelectric power plants?

- Steel pipes are used in the construction of hydroelectric power plants for various purposes, such as transporting water, containing and directing the flow of water, and supporting the weight of turbines and other equipment. They are typically used for penstocks, which are large pipes that carry water from the dam to the turbines, and for discharge pipes that release water back into the river. The strength and durability of steel pipes make them ideal for withstanding the high pressure and heavy loads involved in hydroelectric power generation.

- Q: How are steel pipes protected during transportation?

- To ensure the safety and integrity of steel pipes during transportation, various measures are taken. One effective approach involves applying protective coatings to the pipes' exteriors. These coatings, such as epoxy or polyethylene, act as barriers against moisture, corrosion, and physical damage. Additionally, bundling the pipes together and securing them with strapping or bands prevents movement and potential collisions while in transit. To provide extra protection against impact and handling, wooden crates or containers may also be used. Furthermore, careful loading and unloading procedures are followed to minimize stress or strain on the pipes. By implementing these protective measures, steel pipes can safely reach their destination without compromising their quality or structural integrity.

- Q: What are the common methods for inspecting the integrity of steel pipes?

- Common methods for inspecting the integrity of steel pipes include visual inspection, ultrasonic testing, magnetic particle testing, radiographic testing, and pressure testing.

- Q: Can steel pipes be bent or shaped?

- Yes, steel pipes can be bent or shaped using various methods such as cold bending, hot bending, or using hydraulic or mechanical equipment.

- Q: How do steel pipes handle chemical substances?

- Steel pipes are highly resistant to chemical substances due to their high strength and corrosion-resistant properties. They can safely handle a wide range of chemical substances without undergoing any significant degradation or damage.

Send your message to us

API Standard Oil and Gas Well Casing Tube K55

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords