Analogue Electronic Truck Scale for Weighing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 50 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

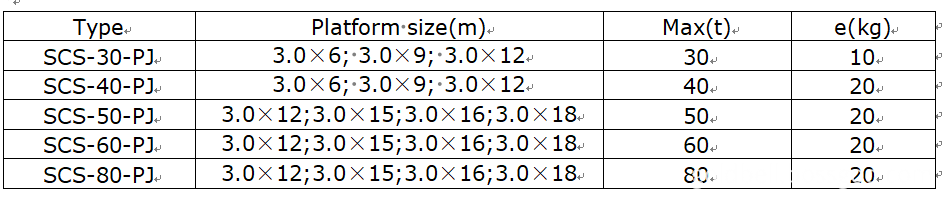

SCS-PJ combination electronic truck scale uses frame structured, has high overall rigidity and strong torsion resistant performance. The platform module is simple, and convenient for container transportation. It can form weighing system together with high accuracy shear beam load cell or column load cell and weighing indicator with excellent performance, rich functions and multiple interfaces.

Its features are high accuracy, good reliability, high intelligence, strong adaptability and convenient installation, adjustment and maintenance.

Platform of SCS/ZCS series analogue modularization electronic truck scale uses frame structured welded by shaped steel, has high overall rigidity and strong torsion resistant performance, and can form weighing system together with bridge type load cell with high accuracy and weighing indicator with excellent performance, rich functions and multiple interfaces. Its features are high accuracy, good reliability, high intelligence, strong adaptability and convenient installation, adjustment and maintenance. It can be widely used in various trades of national economic building and for weighing goods on truck. This product is selected as national new product by State Economy and Trade Commission in 1998.

Our company also produces load cell, strain gauge, weighing indicator and scales such as platform scale and hopper scale.

- Q: I would like to start testing and reconditioning some electrical equipment and I'm wondering what device or devices I can use to out put a specified voltage/amperage either AC or DC.for instance I have an electric motor that needs 5v 20amps, and I require a device that would allow me to plug into a wall outlet and regulate the voltage and amps to the proper levels for testing this device.hopefully that makes sense, thanks

- No, you cannot regulate voltage AND current at the same time. In your example, you apply a regulated 5 volts to the motor, and measure the current drawn, under load. It should be close to 20 amps. What you need are regulated DC power supplies to cover the range of the motors you are interested in. A regulated voltage supply with a current limit will do fine. Regulated AC supplies are more difficult, but I think all you need is an adjustable supply, for example, by use of an adjustable transformer (Variac) and other transformers to change the voltage, again, to the voltages of interest to you. .

- Q: Curiosity just got the best of me. To be electrocuted one should make a complete circuit, right? What if you just touch the live wire and nothing else, you're not standing on anything, no ground. you're in mid air. Any thoughts? Thanks

- No. Your comment about a complete circuit is correct. Under the conditions you state you will not be electrocuted. One exception would be if the line frequency and voltage was high and you had substantial capacitance to ground you might be electrocuted.

- Q: I payed the bill and put in the shutoff notice for the 18th, not the 16th! Jesus Christ! I still have shite I have to move!

- I would be very pissed, you should go complain to the people

- Q: I want to run an appliance that uses DC 5V 2.5A at 6 watts consumption using an adapter from the cigarette lighter socket. I have a standard 12v car battery in the small car. Do i need to get a bigger battery/more batteries, special alternator, or something else to run this appliance permanently?Is there an online calculator to help me work out how much battery power i need?Many Thanks to all answerers.

- as was said, 5 volts at 2.5 amps is 12 watts, not 6. But either way, that is a small amount of power for a car battery. Typical batteries have a capacity of about 1000 watt-hours, so the 12 watt load would work for 80 hours, although I'd limit it to well less than 40 for safety. With the engine running, there is no problem, you can run it as long as you want. It's when you have a load of 50 amps or more when you have to worry about a second battery, etc. .

- Q: Hi, I was wondering if anyone had any information on this car (specifically around a 2003 model) because I was planning to purchase one. From searching on google all I could manage to find was that they were sturdy, safe cars that cost a lot to repair, which I figured since it's a mercedes. Thanks!

- C Class had a lot of problems on electrical equipments, but most of them were correct by 2003. I'm having a C 230 2.5 V6, it's not Kompressor. I've been driving it for more than a year already and there isn't any problem. I put in both 95 octane and sometimes E10 and it doesn't have any problem except sometimes the ! sign shows up on the metre. But, I was told before by Mercedes engineer that the car might get confused on different octane or mixture of the petrol. I stop the engine and start again and the sign disappear. C class from 2007 onward has the sensor to measure the octane of the petrol you put in. It takes from 91 to 98 without problem. It's a good car, I haven't paid more than engine oil and some filters for the first year. Each time cost me less than 200 dollars. I have the AMG version, the car is lower and suspensions are very stiff. It grips the road very well, and I can do more than 200 KMH.

- Q: How can I ensure my computer is properly backed up and the back-up files are unaffected by the sun? Would putting everything on CDs and DVDs work? Which would be better; an external hard disk drive or an external optical hard drive or jusr DVDs/CDs?

- The okorder

- Q: I sprayed electrical cleaning fluid, which evaporates really fast, into my ipod touch's headphone jack, seeing as it was giving me problems having to adjust the tips of the audio equipment I hooked it up too, I should have used a q tip, and I sprayed it into the connector port as well. and my screen, well. Its kind of, weird, and I am kinda angry about it but then agian, its really cool lol Its like, making these 3d bubbles of darkness on the screen, it doesent go completely out, but it gets darker in some areas, and its really bright in the other If I have a pure white backround showing on my ipod, it looks like I am looking at a cloud. a horribly, vivid, cloud, for a screen Any suggestions or reasons why this might have happened? it looks like fluid got on something and somehow never dried, and is like, being displayed on the screen underneath it, but I Know I did not spray that much . I screwed up dident I Technically its still good to me though.

- Yeah, you kind of messed up. An electrical cleaner isn't necessarily meant for electronics, and especially not plastics. If you look at the can again, it could well have a caution on it about being careful around plastics. Even many electronic cleaners tell you to test it on a plastic case in some place it won't show before spraying. Whether the chemical ate the plastic or the thermal shock of the rapid evaporation caused the damage is hard to tell, but I'm guess the cleaner ate the plastic a bit.

- Q: A. Lockout/Tagout involves placing a physical lock and a tag on electrical equipmentB. Lockout/Tagout is necessary prior to working on electrical equipmentC. Lockout/Tagout is intended to ensure that electricity is not returned to the equipment by anyone until it is safe.D. Lockout/Tagout is to be used only in extreme cases of potential electrical hazard.

- D is not true - a lock out tage is used whenever applying electricity to the circuit would result in dangerous conditions. When repair work is being done on the circuit equipment for example. Lock out tage are used for more then just electrical too.

- Q: I am planning to buy a big guitar amp from america and you dont want to mess around with something as powerful as that so i want to know is there suitable adapters out there for such a job? because i heard that some electrical equipment from America will eventually burn out if you use it in Ireland!!help!?!?!

- In America: 110V 60Hz in Ireland 240V 50Hz. Don't just plug in there. See first if it ranges from 110-240 V and it accepts 50 - 60 Hz.

- Q: i have 1 electrical equipment .its data sheet showing .power details, 100VAC to 240 VAC 50-60Hz, 15watts, how can i calculate power consumption of this unit,i need formula also,

- You have the number, 15 watts. but that is a maximum, the actual power will be less than that. If you need the actual power, you cannot calculate it, you have to measure it. .

Send your message to us

Analogue Electronic Truck Scale for Weighing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 50 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches