Aluminum Trailer Siding Sheets 5xxx Hot Rolled Oregon

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Sheets 5xxx Hot Rolled Description

Aluminum Sheets 5xxx Hot Rolled is cut from aluminum coils 5xxx. Aluminum Sheets 5xxx Hot Rolled has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum Sheets 5xxx Hot Rolled is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of Aluminum Sheets 5xxx Hot Rolled

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

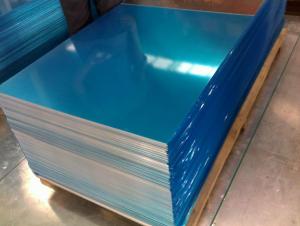

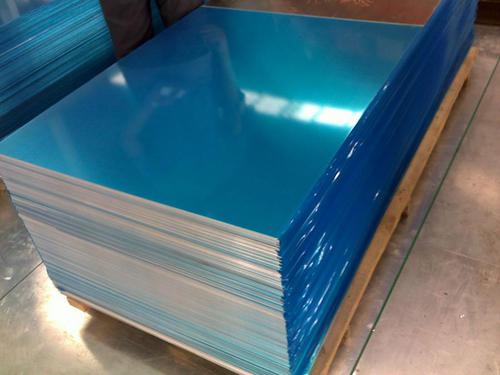

3.Aluminum Sheets 5xxx Hot Rolled Images

4.Aluminum Sheets 5xxx Hot Rolled Specification

| Alloy | AA5xxx (AA5052,AA5083,AA5754 etc.) |

| Temper | H14,H16,H18,H22,H24,H26,H32,O/F |

| Thickness | 0.2mm-100mm |

| Width | 30mm-1700mm |

| Standard | GB/T 3880-2006 |

5. FAQ of Aluminum Sheets 5xxx Hot Rolled

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Aluminum Sheets 5xxx Hot Rolled products.

B.When will you deliver the products?

The Aluminum Sheets 5xxx Hot Rolled will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: Are aluminum sheets suitable for welding?

- Aluminum sheets are indeed suitable for welding, being widely used in various industries for their lightweight, corrosion resistance, and excellent thermal conductivity. However, welding aluminum presents challenges due to its high thermal conductivity and the formation of an oxide layer on its surface. Nevertheless, successful welding of aluminum sheets can be achieved with proper techniques and equipment. Tungsten Inert Gas (TIG) welding and Metal Inert Gas (MIG) welding are commonly employed for aluminum welding. These processes allow for precise heat control and the use of shielding gases to protect the weld pool from oxidation. In addition, achieving strong and reliable welds requires proper surface preparation, cleaning, and the use of specialized aluminum welding wires or rods. Overall, while specific techniques and equipment may be necessary, welding aluminum is feasible and widely practiced in various industries.

- Q: Can the aluminum sheets be used for manufacturing medical equipment?

- Yes, aluminum sheets can be used for manufacturing medical equipment. Aluminum is a versatile and widely used material in various industries, including healthcare. It has several properties that make it suitable for medical equipment manufacturing. Firstly, aluminum is lightweight yet durable, which is beneficial for portable medical devices. It allows for easier handling and transportation of equipment, especially for healthcare professionals who may need to move them frequently. Secondly, aluminum has excellent corrosion resistance, making it suitable for medical applications where cleanliness and hygiene are crucial. It can withstand disinfection processes without deteriorating, ensuring the longevity of the equipment. Additionally, aluminum can be easily sterilized, which is essential for medical equipment. It can withstand high-temperature sterilization methods, such as autoclaving, without any adverse effects on its structural integrity. Moreover, aluminum is an excellent conductor of heat and electricity. This property is advantageous for medical equipment that requires efficient heat dissipation or electrical conductivity, such as surgical instruments or diagnostic tools. Furthermore, aluminum is a non-toxic material, making it safe for medical use. It does not leach harmful substances, ensuring that it does not pose any health risks to patients or healthcare professionals. In conclusion, aluminum sheets can indeed be used for manufacturing medical equipment due to their lightweight, durability, corrosion resistance, sterilization capabilities, thermal and electrical conductivity, and non-toxic nature. These properties make aluminum a suitable choice for various medical applications, contributing to the advancement of healthcare technology.

- Q: Is it feasible to utilize aluminum sheets in constructing carports and garages?

- <p>Yes, aluminum sheets can be used for carports and garages. They are lightweight, durable, and resistant to corrosion, making them a popular choice for outdoor structures. Aluminum sheets are also easy to install and maintain, and they can be designed to withstand various weather conditions. However, it's important to consider the thickness and quality of the aluminum to ensure it can bear the weight and withstand potential damage from weather elements.</p>

- Q: Can aluminum sheets be used in food packaging?

- Indeed, aluminum sheets find widespread application in the realm of food packaging. The utilization of aluminum in this context is prevalent owing to its exceptional capability to shield food from detrimental elements like light, oxygen, moisture, and other external agents that may cause spoilage or contamination. Notably, aluminum sheets possess the qualities of being lightweight, long-lasting, and resistant to corrosion, rendering them perfectly suitable for an array of food packaging formats, including foil wraps, containers, trays, and pouches. Moreover, the recyclability of aluminum further solidifies its status as an eco-friendly option for food packaging.

- Q: Is it possible to use aluminum sheets as a material for the exterior walls of a building?

- <p>Yes, aluminum sheets can be used for exterior siding. They are known for their durability, resistance to corrosion, and low maintenance requirements. Aluminum siding is lightweight, easy to install, and can be painted to match various architectural styles. It is also resistant to harsh weather conditions and pests, making it a popular choice for many homeowners and builders. However, it is important to ensure proper installation to maximize its benefits and longevity.</p>

- Q: Can aluminum sheets be used for architectural applications?

- Architectural applications can definitely make use of aluminum sheets. Aluminum, being a lightweight and versatile material, offers numerous advantages for architectural projects. It possesses durability, resistance to corrosion, and the ability to withstand extreme weather conditions, making it an ideal choice for different architectural applications like roofing, cladding, facades, windows, doors, and decorative elements. The availability of aluminum sheets in various thicknesses, finishes, and colors allows architects and designers to achieve their desired aesthetic while maintaining structural integrity. With the material's flexibility in being easily shaped, bent, and formed into complex designs, architects are provided with creative freedom and flexibility. Aside from its aesthetic appeal, aluminum is also an environmentally sustainable choice for architectural applications. It is highly recyclable, contributing to a high recycling rate and promoting eco-friendly options. The use of aluminum sheets in architectural projects helps in reducing the carbon footprint and promoting sustainable design practices. Moreover, aluminum sheets offer excellent thermal and acoustic properties that contribute to energy efficiency and sound insulation in buildings. The material aids in reducing energy consumption and enhancing occupant comfort, making it an attractive option for architects and building owners. In conclusion, the versatility, durability, sustainability, and aesthetic appeal of aluminum sheets make them a popular choice for architectural applications. They provide numerous benefits and can be utilized in various ways to create stunning architectural designs while ensuring long-lasting performance.

- Q: What are the specific rules or benchmarks that must be followed when utilizing aluminum sheets for construction purposes?

- <p>Yes, there are special regulations and standards for using aluminum sheets in construction projects. These include material specifications, thickness, and strength requirements as per the American Society for Testing and Materials (ASTM) standards, such as ASTM B209 for aluminum sheet and plate. Additionally, the International Building Code (IBC) and local building codes provide guidelines for the use of aluminum in construction. These standards cover aspects like fire resistance, structural integrity, and weather resistance. Compliance with these regulations ensures safety, durability, and compliance with construction laws.</p>

- Q: The diameter of a hole drilled through aluminum at 22°C is 7.50 mm. Find the diameter and the area of the hole at 89°C.

- If i was once you, i might depart a small 1cm gap on the high and cover it with mesh - these round ones don't appear to allow a lot air flow in any respect in my viv and i have three... I have a tendency to simply leave the glass open a bit of at both aspect. You'll have got to use a great mesh although to stop bugs escaping via it. BTW - i think you will have to make it slightly deeper... 1.5 at least in case you are maintaining reps a good way to grow to 12inch plus.

- Q: 5052 can aluminum plate be machined with laser cutting machine?

- Can cut, but the incision does have cut marks, if processing 3 mm below the thickness, incision quality will be better.

- Q: Can aluminum sheets be stamped or pressed?

- Certainly, one can stamp or press aluminum sheets. Aluminum, being an extremely malleable metal, lends itself readily to shaping and forming via diverse manufacturing methods. Stamping and pressing are frequently employed techniques for fashioning elaborate designs, shapes, and patterns onto aluminum sheets. These procedures entail the exertion of pressure upon the sheet by means of specialized equipment, such as stamping presses or hydraulic presses, with the aim of altering the material and achieving the desired form. Industries such as automotive, aerospace, construction, and manufacturing extensively rely on stamping and pressing, as aluminum sheets are commonly chosen for their lightweight, durable, and corrosion-resistant attributes.

Send your message to us

Aluminum Trailer Siding Sheets 5xxx Hot Rolled Oregon

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords