5ft X 5ft Marine Alloy Hot Rolled Aluminum Sheets

- Loading Port:

- Shanghai

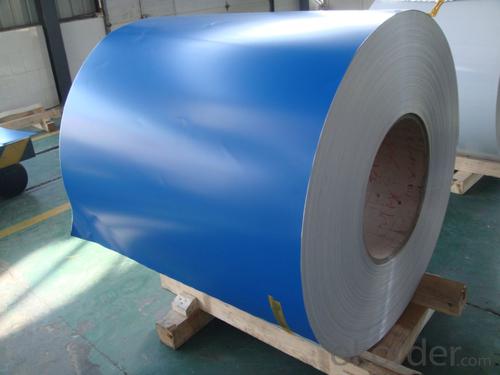

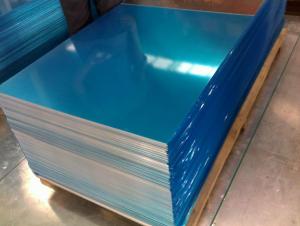

- Payment Terms:

- TT or LC

- Min Order Qty:

- 9 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled , hot rolled aluminum sheet are both widely used

in the field of construction, etc.the grade are as follows: 1010, 1050,1060,1100, 2024,

3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm, 1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range:

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 5 tons/each size.

How many tons did you export in one year?

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet,

mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Are aluminum sheets suitable for wastewater treatment applications?

- Indeed, aluminum sheets prove to be suitable for wastewater treatment applications. With its versatility, aluminum presents several advantages when utilized in wastewater treatment processes. Firstly, aluminum sheets exhibit a high resistance to corrosion, a crucial feature given the harsh and corrosive environment of wastewater treatment plants. This resistance ensures that the aluminum sheets remain intact and unaffected by the chemicals present in the wastewater, thereby preserving their structural integrity. Moreover, aluminum sheets possess exceptional thermal conductivity properties, enabling efficient heat transfer in processes such as wastewater disinfection. This thermal conductivity facilitates the effective elimination of harmful bacteria and contaminants from the wastewater, thereby enhancing the overall treatment process. Furthermore, aluminum sheets are not only lightweight but also durable, making them easy to handle and install in wastewater treatment systems. This characteristic also contributes to their cost-effectiveness, as they require less maintenance and are less susceptible to damage compared to alternative materials. Additionally, aluminum is a sustainable material that can be recycled, thus reducing the environmental impact of wastewater treatment applications. Recycling aluminum sheets aids in the conservation of natural resources and minimizes energy consumption, making it an environmentally friendly choice. In conclusion, aluminum sheets offer a multitude of advantages for wastewater treatment applications. Their corrosion resistance, thermal conductivity, lightweight nature, and recyclability render them a suitable and efficient material for use in wastewater treatment processes.

- Q: I am thinking about getting a MacBook Aluminum or a MacBook white. The Aluminum is 2.0 GhZ and the MacBook White is 2.16 GhZ. which should i get? also i am really wondering if you can upgrade the processors in both MacBooks..... Please give me link if you can. THANKS!!

- If okorder /... I'm not sure about the processor's. I dont use Mac that often!

- Q: Everyone said that the pre roll coated aluminum plate, what is pre roll coating?

- Beforehand, beforehand, mean,Roll coating is a paint coating process, relative to spraying, such as powder, wall coating, coating or roller coatingThe coating is applied to the surface of the aluminum sheet by a roller or steel roller. Roll coating

- Q: What's the maximum size of 3 mm thick aluminum sheet?

- To see what is your production process requirements? If it is hot extrusion, the width of the largest flatness requirements under the condition of low at about 300mm. If the processing technology of aluminum strip is hard to say, to see the production capacity of the equipment (the size and size is the maximum size of the majority in the 1.2) to 1.5 meters wide, the length of one hundred meters above

- Q: Does aluminum sheet require special handling during transportation?

- Yes, aluminum sheets typically require special handling during transportation. This is because aluminum is a lightweight yet fragile material that can easily dent, scratch, or bend. To prevent such damages, it is important to handle aluminum sheets with care, avoiding rough handling, excessive bending, or stacking heavy objects on top. Additionally, protective measures like using padding or wrapping the sheets in protective material can help ensure their safe transportation.

- Q: What are the weight limitations for aluminum sheets in different applications?

- The weight limitations for aluminum sheets vary depending on the specific application. Factors such as the thickness, alloy, and intended usage play a significant role in determining the maximum weight that aluminum sheets can support. It is essential to consult the manufacturer's specifications or engineering professionals for the precise weight limitations in different applications.

- Q: Can aluminum sheets be coated with other materials?

- Aluminum sheets have the capability to undergo a process called aluminum sheet coating or aluminum sheet finishing, wherein they are coated with different materials. This coating process serves several purposes, such as enhancing their appearance, protecting against corrosion, increasing durability, and providing insulation. Painting, anodizing, laminating, and powder coating are among the various methods available to coat aluminum sheets. Each method offers unique advantages and is selected based on the desired outcome and intended usage of the coated aluminum sheet. Coating aluminum sheets with other materials allows for customization, versatility, and enhanced functionality in a wide range of industries, including construction, automotive, aerospace, and consumer goods.

- Q: What is the typical tensile strength of aluminum sheets?

- The specific grade or alloy being used can cause variations in the typical tensile strength of aluminum sheets. Typically, the tensile strength of aluminum sheets falls between 20,000 and 50,000 pounds per square inch (psi). It is worth mentioning that this is a wide range and the exact tensile strength can be affected by factors such as the sheet's thickness, the manufacturing process, and any additional treatments or coatings applied to the aluminum. Hence, it is advisable to refer to the manufacturer's or supplier's specifications for accurate information regarding the tensile strength of a particular aluminum sheet.

- Q: How do you form curves or shapes in aluminum sheets?

- There are several methods to form curves or shapes in aluminum sheets. One common technique is called bending, where the sheet is clamped and then gradually bent using a mechanical press brake or a hammer. Another method is called roll forming, which involves passing the aluminum sheet through a series of rollers to achieve the desired shape. Additionally, aluminum sheets can be molded or pressed into curves or shapes using specialized tools or dies.

- Q: This question asks for various methods through which aluminum sheets can be recycled and repurposed.

- <p>Aluminum sheets can be recycled and reused in several ways: 1. Melting and Reformation: The most common method is to melt down the aluminum and reform it into new products. 2. Mechanical Recycling: This involves shredding and compacting the aluminum sheets to be used as raw material in new products. 3. Energy Recovery: The heat generated from burning aluminum can be used to produce energy. 4. Alloying: Aluminum can be combined with other metals to create new alloys with different properties. 5. Reuse in Construction: Aluminum sheets can be reused in construction projects, such as facades or roofing. 6. Manufacturing: They can be used in manufacturing processes to create new aluminum products like cans, foils, and automotive parts. Proper recycling of aluminum reduces environmental impact and conserves resources.</p>

Send your message to us

5ft X 5ft Marine Alloy Hot Rolled Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 9 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords