Mill Finish Five Bar Aluminum Chequer Plate - Aluminum Trailer Siding Sheets Ontario

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Five Bar Aluminum Chequer Plate

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

PAINT THICKNESS | Top:18--25um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

2. Application of Mill Finish Five Bar Aluminum Chequer Plate

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Five Bar Aluminum Chequer Plate

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

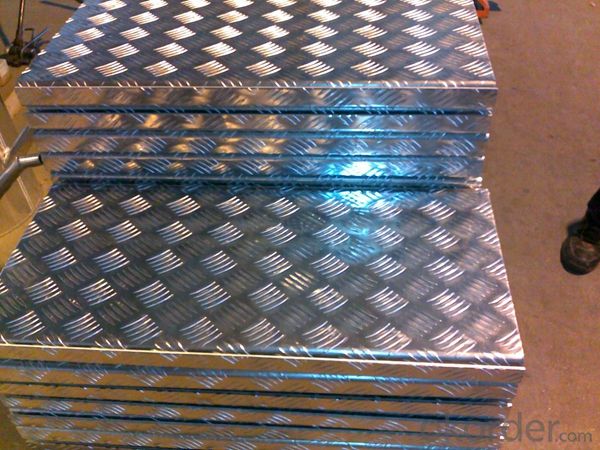

5. Image of Mill Finish Five Bar Aluminum Chequer Plate

6. Package and shipping of Mill Finish Five Bar Aluminum Chequer Plate

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum sheets be used for industrial shelving?

- Yes, aluminum sheets can be used for industrial shelving. Aluminum is a lightweight and durable material that offers several advantages for industrial shelving applications. It is resistant to corrosion, which makes it suitable for environments that are exposed to moisture or harsh chemicals. Aluminum's strength-to-weight ratio is also advantageous, as it allows for the construction of sturdy shelves that can hold heavy loads while remaining relatively lightweight. Additionally, aluminum is easy to maintain, as it does not require painting or sealing like other metals. Overall, aluminum sheets are a practical choice for industrial shelving due to their durability, corrosion resistance, and lightweight properties.

- Q: This question asks for an explanation of the various types of paint that can be applied to aluminum sheets.

- <p>Aluminum sheets can be coated with different types of paints to enhance their appearance, durability, and functionality. The common types include: 1) Acrylic Paints: Known for their flexibility and resistance to weathering and UV rays. 2) Polyester Paints: These offer excellent adhesion and gloss. 3) Epoxy Paints: Known for their chemical resistance and durability. 4) Polyurethane Paints: They provide a tough, scratch-resistant finish. 5) Powder Coatings: These are electrostatically applied and offer a durable, weather-resistant finish. 6) Fluoropolymer Coatings: They provide excellent resistance to chemicals and UV degradation. Each type has specific properties that make it suitable for different applications and environments.</p>

- Q: Are aluminum sheets suitable for harsh weather conditions?

- Aluminum sheets are highly suitable for harsh weather conditions due to their exceptional properties. Aluminum is a lightweight yet durable material that offers excellent resistance against corrosion, rust, and UV radiation. This makes it particularly resilient against the damaging effects of extreme weather conditions such as heavy rain, snow, high winds, and intense sunlight. Furthermore, aluminum has a high strength-to-weight ratio, allowing it to withstand the pressure exerted by severe weather without sustaining significant damage. Additionally, aluminum sheets can be coated with protective finishes such as anodization or powder coating, further enhancing their ability to withstand harsh climates. Overall, aluminum sheets are an excellent choice for applications requiring resilience in harsh weather conditions.

- Q: Explain the pros and cons of utilizing aluminum sheets in the construction of car body panels.

- <p>Aluminum sheets offer several advantages for car body panels, such as reduced weight, which can improve fuel efficiency and handling. They also have high resistance to corrosion, enhancing the vehicle's durability. Additionally, aluminum is easier to recycle, contributing to environmental sustainability. However, there are downsides, including higher cost compared to steel, which can affect the vehicle's price. Aluminum is also less malleable, making it more challenging to repair after accidents, potentially leading to higher repair costs. Furthermore, aluminum's lower strength compared to steel can necessitate thicker panels to achieve the same structural integrity, which may offset some of the weight savings.</p>

- Q: What is the thickness range of aluminum sheets?

- The thickness range of aluminum sheets can vary depending on the specific application and industry standards. However, commonly available aluminum sheets typically range in thickness from 0.006 inches (0.15mm) to 0.25 inches (6.35mm). For more specialized applications, thicker aluminum sheets may be available. It is important to note that different alloys and grades of aluminum may have different thickness ranges, so it is essential to consult the specific requirements and standards of the intended use case.

- Q: Are aluminum sheets suitable for automotive body panels?

- Yes, aluminum sheets are suitable for automotive body panels. Aluminum is lightweight, corrosion-resistant, and strong, making it an ideal material for manufacturing car body panels. It helps improve fuel efficiency, enhances performance, and reduces overall vehicle weight, making it a popular choice among automakers.

- Q: Aluminum wiring can be a fire hazard because it can oxidize, or combine with oxygen..

- Well, aluminum oxide is Al2O3, right? So for every 2 aluminum atoms there are 3 oxygen atoms, So, if you have three moles of aluminum, you'll need 4 and a half moles of oxygen to react completely with the aluminum. One mole of oxygen atoms weighs 16 grams, so 4.5 moles weighs 72 grams, right? Now it could be that your teacher told you three point zero zero moles of aluminum to get you to use two significant figures, so if you've studied significant figures you may want to look up a more accurate number for the atomic weight of aluminum, and carry the calculation through to three significant figures. Otherwise, 72 is a fine answer.

- Q: I want to make a dress from aluminum cans. However, aluminum is very sharp once cut. So, do you thing there is a possible way to make the cut edges less sharp? Would sanding the edges help?

- It's a soft metal so sanding and filing would work. You could also consider folding over the sharp edges (like a hemline) using a pliers or similar tool

- Q: Can aluminum sheets be used for protective barriers?

- Yes, aluminum sheets can be used for protective barriers. Aluminum is a lightweight and durable material that offers good resistance against impact, corrosion, and fire. It can be easily fabricated into sheets, making it suitable for various applications such as protective barriers in construction, transportation, and industrial settings.

- Q: How does aluminum sheet perform in extreme temperatures?

- Due to its unique properties, aluminum sheet exhibits exceptional performance in extreme temperatures. One of its key advantages is its remarkable thermal conductivity, enabling it to efficiently transfer heat. This characteristic allows aluminum sheet to quickly adapt to extreme temperatures, preventing the occurrence of warping or cracking that may be experienced with other materials. Moreover, aluminum possesses a high melting point of approximately 660 degrees Celsius, rendering it highly suitable for usage in high-temperature environments. It remains structurally stable, retaining its strength and integrity even when subjected to intense heat. Additionally, aluminum exhibits a low coefficient of thermal expansion, resulting in minimal expansion and contraction in response to temperature fluctuations. This particular attribute enables aluminum sheet to maintain its shape and dimensions even when exposed to drastic temperature changes. Furthermore, aluminum showcases exceptional corrosion resistance, further augmented by the formation of a natural oxide layer on its surface. This oxide layer serves as a protective barrier against chemical reactions, safeguarding the aluminum from deterioration even in harsh environments or extreme temperatures. In conclusion, aluminum sheet demonstrates outstanding performance in extreme temperatures due to its high thermal conductivity, high melting point, low coefficient of thermal expansion, and excellent corrosion resistance. These properties establish it as a reliable choice for a multitude of applications, including the aerospace, automotive, and industrial sectors, where the ability to perform under extreme temperatures is of utmost importance.

Send your message to us

Mill Finish Five Bar Aluminum Chequer Plate - Aluminum Trailer Siding Sheets Ontario

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords