Maury Aluminum Foil - Aluminum Products from China for Building Material/ Food Package/ Laminated /HHF/ Lidding Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Foil

Thickness | 0.005mm-0.2mm |

Popular Thickness | 0.01mm/0.02mm/0.025mm/0.03mm/0.06mm/0.08mm |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

2. Application of Aluminum Foil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum Foil

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

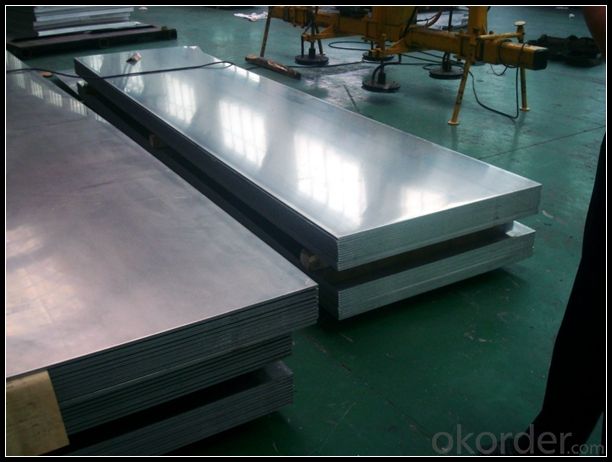

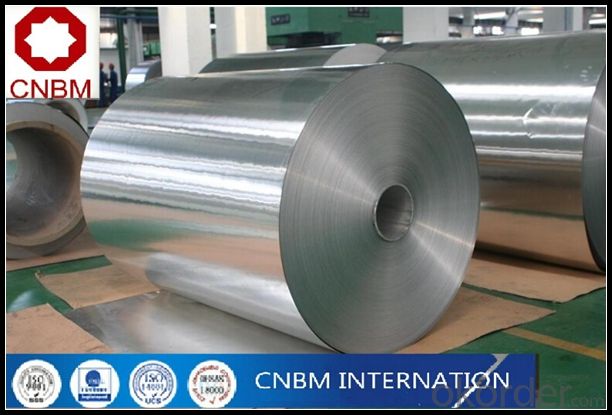

5. Image of Aluminum Foil

6. Package and shipping of Aluminum Foil

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Aluminum reacts with Sulfuric acid to produce aluminum sulfate and hydrogen gasHow many grams of aluminum sulfate would be formed if 250 g H2SO4 completely reacted with aluminum? 2Al(s) + 3H2SO4 -gt; Al29SO4)3(aq)+3H2(g)

- oven thermometers are inexpensive at any housewares aisles in any store! get one to check the temp of your ovenSame with timers! maybe the one on your stove is old and slow! pan should have nothing at all to do with whether your breads get done or notI have used those aluminum pans for gift giving without removing the bread from the pan, very old sheet steel pans, new heavy aluminum pans, ceramic pans, pyrex pans, corning pans, and cast iron pans! I can put a bunch of different pans in the oven at the same time and get good results from temperature and time recommended.

- Q: how to make awesome buffalo wings?

- I did a project in art and i used that stuffAll u do is get 2 thin metal coat hangers, then cut 2 strips out of the middle of them, after that tie the 2 hanging parts together from were u hang it on the rack, its easy to bend so shape it out then wrap old newspaper around it , then u cover it in foil,make shure to smooth it out 2, put plaster over the top of the foil let dry and if u want to PAINT!;D well i got an A on mine and it went well Traviling Art Show 2

- Q: I was wondering how do I find the geometry of hexafluoroaluminate, AlF6 3- ? I was trying to use the orbital here to solve it I see its d2sp3 which is related to octahedral geometry, but would about the 3 extra electrons?

- Most any winter blanket will doAsk at the tack shop where you will buy itJust remember that with a blanket there are many days in the fall and spring when you'd want the blanket on at night but not during the dayIt can be a lot of trouble to put it off and on all the time unless it will be done by the staff at the boarding facilityIf not.really consider not clipping and not using a blanket.

- Q: What is a good chicken wing recipe?

- Here's the easiest C/W recipe everPreheat oven to 500 degreesI sometimes recycle grocery bags and use them for this recipePut the wings in the grocery bag, sprinkle them generously with Lemon Pepper or just salt 'n fresh ground black pepperThen close up the bag tightly and shake well to distribute the seasoningSet it aside while you get out a sheet pan with a wire grate that fits in itIf you don't have this, use a broiler pan, lined with aluminum foil and lightly sprayed with cooking spray Place the wings on the grate or broiler pan, not touching, in one layerPut in the oven, on the lower, second rack from the bottom, and roast for 10 minutesThen turn the wings over and roast another 10 minutesC/W are done at 180 degrees temperature, according to an instant digital-read thermometerOnce you try this recipe, you'll go back to it again and again.

- Q: I am a sophmore in high school and really want a creative and fun costumeSomething cute but not sluty or really covered upI don't want a generic costume like a witch, fairy or catthings like hipster princess, the sun drop girl, or a landshark (if you watch jenna marbles)Anything from pop culture would be good or anything just fun and funnyIt would be great if it could be done in a group too but it doesn't have to beI don't want to buy a costume either, it would be good if it could just be home made.

- i have got one of the fish tank themomiters at the bottom on my snake cage and it works great it even tells u the humidity

- Q: I dont have parchment paper to line the bottom of my cake pan, can i just use non-stick aluminum foil?

- Yea, you can but it won't be as prettyUse some crisco and smear it on really thin then sprinkle some flour on it and tap it aroundIt will work better than al foilFoil also will alter the baking time.

- Q: I love to bake but I don't eat what I bakeIf I bake cupcakes and freeze them, do I freeze the unbaked batter or bake and then freeze?

- Bake then freeze :) They'd be good half frozen too! ever hear of frozen cookies or frozen wedding cake? Why go through all the trouble twice? BAKE THEN FREEZE! I stand by it, lol.

- Q: PLEASE HELP ON SCIENCE PROJECT!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!?

- Put it in small fabric sachets and tuck it into drawers and closetsOr give as presents.

- Q: when you recycle cans in michigan will they accept them crushed or do they only take cans that aren't crushed?

- Heat vegetable oil in a deep fryer or a large frying pan with tall sides up to about 350-400 degrees Cut potatoes into sticks Put potato sticks into hot oil Cook for 5-6 minutes, or until they are your preferred level of brown Salt Eat

- Q: I learned that Obama's sister Auma went to the same university as me.

- I learnt that the very first food eaten by a U.S astronaut in outer space was applesauce which was prepared along with aluminum tubes of beef stew.

Send your message to us

Maury Aluminum Foil - Aluminum Products from China for Building Material/ Food Package/ Laminated /HHF/ Lidding Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords