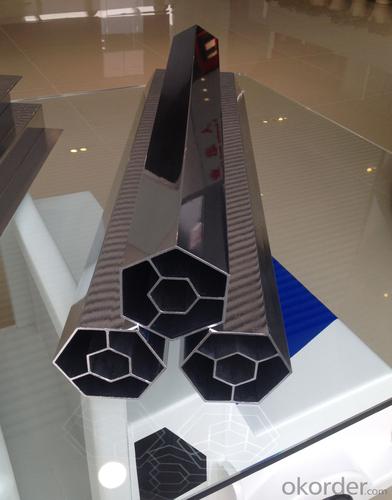

Aluminum Pipes for Vehicle Structure Aluminum Profile

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are the largest aluminum profilemanufacture in

Material | Alloy Aluminum 6063,6061,6005,6082 or customer nominated |

Temper | T3, T4, T5, T6 and other |

Surface | Anodize, electrophoresis, Mill,etc |

Colour | -- |

Length | Not more than 16 meters |

Good Package | Inner plastic film /outside carton/wooden pallets |

Payment Method | T/T, L/C, etc |

Delivery Time | Normally 2-4 weeks, Delivery time can be consulted. |

Press Machine | 500-12500 tons all together 93 press lines. |

Fabrication | 1. Car body; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO/TS 16949,DNV,IRIS,CCS,AFA,etc. |

Dies | 1. Using our dies, no fee; |

2. Using customer drawing, opening dies, usually about 5~50 tons then the dies cost can be refunded. | |

3. Die cost is negotiable base on the order quantity | |

Capability | Annual output 800,000 tons |

- Q: Are aluminum pipes compatible with different pipe joining methods?

- Yes, aluminum pipes are compatible with various pipe joining methods including welding, threading, soldering, and compression fittings.

- Q: Are aluminum pipes suitable for oil refineries?

- Yes, aluminum pipes are generally not suitable for oil refineries due to their lower corrosion resistance compared to other metals like carbon steel or stainless steel.

- Q: What is the maximum operating temperature for aluminum pipes?

- The maximum temperature at which aluminum pipes can operate varies due to factors like alloy composition, specific application, and insulation or heat transfer. Generally, aluminum pipes can withstand temperatures up to around 300-400 degrees Fahrenheit (150-200 degrees Celsius) without experiencing notable distortion or structural harm. It is crucial to remember that surpassing this temperature range can result in reduced mechanical strength and potential pipe failure. Hence, it is advisable to seek guidance from the manufacturer or a qualified engineer to ascertain the precise maximum operating temperature for your aluminum pipes based on the aforementioned factors.

- Q: What are the advantages of using aluminum pipes over other materials?

- Using aluminum pipes instead of other materials offers several advantages. Firstly, aluminum pipes are lightweight, making them easy to handle and transport compared to heavier materials like steel or copper. This makes them a popular choice in industries where reducing weight is important, such as aerospace and automotive. Secondly, aluminum pipes have excellent corrosion resistance. They naturally form a protective oxide layer that prevents rust and corrosion, making them suitable for use in moist, chemical, or extreme weather conditions. Additionally, their resistance to corrosion means they last longer and require less maintenance. Furthermore, aluminum pipes have high thermal conductivity, meaning they efficiently transfer heat. This makes them ideal for applications that require heat exchange or thermal management, such as HVAC, refrigeration, and automotive cooling systems. Another advantage of aluminum pipes is their versatility. They can be easily formed into different shapes and sizes due to their malleability. This makes them suitable for a wide range of applications, from plumbing and irrigation systems to structural frameworks and electrical conduits. Lastly, aluminum pipes are environmentally friendly. They are highly recyclable, and the recycling process requires much less energy compared to their initial production. By using aluminum pipes, companies can contribute to sustainability efforts by reducing their carbon footprint and waste. In summary, the benefits of using aluminum pipes include their lightweight nature, excellent corrosion resistance, high thermal conductivity, versatility, and environmental friendliness. These qualities make aluminum pipes a preferred choice in various industries, providing efficiency, durability, and sustainability.

- Q: How can the fridge aluminum pipe trachoma be filled?

- 2. glue fill, with good brothers glue, cold resistant coating, and then wrapped around a layer of gauze, dried again, it can be mended.

- Q: How do aluminum pipes perform in seismic zones?

- Aluminum pipes have shown good performance in seismic zones due to their inherent characteristics of being lightweight and flexible. These properties allow them to absorb and dissipate seismic energy, reducing the risk of structural damage or failure. Additionally, aluminum pipes have high ductility, enabling them to withstand ground movements during earthquakes without experiencing significant deformation or rupture. Overall, aluminum pipes are considered a reliable choice for use in seismic zones.

- Q: Are aluminum pipes suitable for wastewater treatment plants?

- Aluminum pipes are indeed a suitable choice for wastewater treatment plants. Their lightweight and corrosion-resistant nature make them perfect for environments where exposure to corrosive substances in wastewater is probable. Moreover, the installation and maintenance of aluminum pipes are hassle-free, resulting in reduced costs and effort for operating the wastewater treatment plant. However, it is crucial to consider several factors, including the type of wastewater being treated, the concentration of chemicals, and the plant's operating conditions, to determine if aluminum pipes are the best fit. Consulting experts and engineers in the field is highly recommended to select the most suitable materials for a specific wastewater treatment plant.

- Q: Can aluminum tubes be sprayed or painted? What type of paint is appropriate? Will the paint come off?

- Can do blister, but brush paint can not eat

- Q: Eddy current demonstrator's working principle: why does the magnet fall at different speeds in different aluminum tubes, while the aluminum tubes are the same?

- When the aluminum block falls, no magnetic flux is produced, so the aluminum block falls short. When the magnet and the conductor block have relative motion, eddy currents will be generated in the conductor, and the action of the eddy current will hinder their relative motion.

- Q: Which kind of strength is good?No, at the moment I don't have any grades!

- In contrast, the cold tolerance capacity of the same specification tube is greater than that of the extruded pipe. Only cold drawing, the mold and its material requirements are very high, so cold drawn pipe prices slightly higher.

Send your message to us

Aluminum Pipes for Vehicle Structure Aluminum Profile

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords