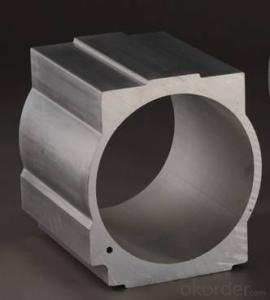

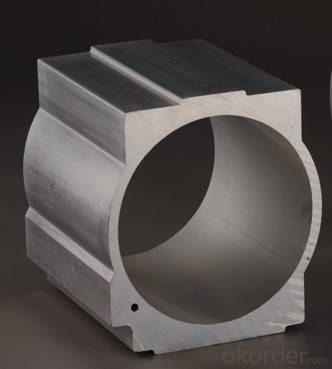

Aluminum Pipe Air Cylinder Shell

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are the largest aluminum profilemanufacture in

Material | Alloy Aluminum 6063,6061,6005,6082 or customer nominated |

Temper | T3, T4, T5, T6 and other |

Surface | Anodize, Mill,rtc |

Colour | Mill |

Length | -- |

Good Package | Inner plastic film /outside carton/wooden pallets |

Payment Method | T/T, L/C, etc |

Delivery Time | Normally 2-4 weeks, Delivery time can be consulted. |

Press Machine | 500-12500 tons all together 93 press lines. |

Fabrication | 1. Air cylinder shell; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO/TS 16949,DNV,IRIS,CCS,AFA,etc. |

Dies | 1. Using our dies, no fee; |

2. Using customer drawing, opening dies, usually about 5~50 tons then the dies cost can be refunded. | |

3. Die cost is negotiable base on the order quantity | |

Capability | Annual output 800,000 tons |

- Q: Can aluminum pipes be anodized?

- Indeed, anodization is a feasible option for aluminum pipes. Anodization involves an electrochemical procedure that amplifies the inherent oxide layer present on the aluminum's surface. Through this method, a resilient and safeguarding coating is formed, offering enhanced resistance against corrosion, improved visual appeal, and additional functional advantages to the aluminum pipes. The process of anodizing can be applied to a diverse range of aluminum items, including pipes, to elevate their efficiency and lifespan.

- Q: We use CNC machining, the best easy to process, the hardness is too low, not good (listen to others say that some aluminum foam will stick to the knife, and some processing is not bright). Online check is said 6063, but to the aluminum shop asked about, say is 6061, buy 50 kilograms first, try to do, but the boss said seems to be another kind, beg you prawns help ah

- The 3 and two lines (2024, 2017, 2011) and seven (7075, 7050) and relatively high hardness, Brinell hardness of about 120-150, the two kinds of materials for aviation aluminum, the price is more expensive (40-90 /KG) range, easy cutting, brightness is also good, but the effect of oxidation as six series. Have not heard who used to do the lamp can also be excluded.4, so you are the most correct is to choose six lines of aluminum to do, and 6061 and 6063, I suggest using 6063, because the 6063 oxidation effect is better than 6061. Currently on the market is 6061 more larger in diameter than the aluminum rod and tube of 20MM (and most not GB, GB material oxidation effect, stable performance, but because of you) the amount is too small, can not find manufacturers directly customized, GB is not a good buy material. Ask more and you should find 6063.

- Q: Are aluminum pipes suitable for marine applications?

- Yes, aluminum pipes are suitable for marine applications. Aluminum is a lightweight and corrosion-resistant material, making it an ideal choice for use in marine environments. It has excellent resistance to saltwater, which is a common element in the marine industry. Aluminum pipes are also highly durable and can withstand extreme weather conditions, including high winds, waves, and impact from debris. Additionally, aluminum has a high strength-to-weight ratio, which allows for the construction of strong and efficient marine structures. Overall, aluminum pipes offer numerous advantages and are widely used in various marine applications, including boat building, offshore structures, and marine pipelines.

- Q: Are aluminum pipes suitable for underground installations?

- Yes, aluminum pipes are suitable for underground installations. They are corrosion-resistant, lightweight, and durable, making them a viable option for various underground applications such as water supply, sewerage systems, and irrigation.

- Q: Can aluminum pipes be used for swimming pool systems?

- Yes, aluminum pipes can be used for swimming pool systems. Aluminum is a popular choice for pool systems due to its durability, resistance to corrosion, and lightweight nature. It is commonly used for piping, especially in areas with high moisture or corrosive conditions, making it a suitable option for swimming pool systems.

- Q: Why is copper pipe used instead of copper aluminum composite tube or aluminium pipe?

- Pipe is widely used. Pipes are used in many industries.Different industries have different characteristics of the industry, and thus have different technical requirements.Pipe is a relatively mature product, each industry has the corresponding technical standards.Detect pipe material, according to the application of pipe industry, select the corresponding product standards, according to the industry needs to detect the corresponding technical indicators.

- Q: Can aluminum pipes be used for building facades?

- Yes, aluminum pipes can be used for building facades. Aluminum is a highly versatile and durable material that is commonly used in construction due to its lightweight nature, corrosion resistance, and ease of installation. Aluminum pipes can be customized to various sizes and shapes, making them suitable for different architectural designs. Additionally, aluminum can be finished with different coatings or finishes to enhance its aesthetic appeal and protect it from environmental factors. Overall, aluminum pipes are a popular choice for building facades as they offer a balance between functionality, durability, and design flexibility.

- Q: Which is the high price of 6063 and 6061 aluminium tubes?

- The same material profiles, the average length of the same unit, the weight of the high price.

- Q: Do aluminum pipes require any anti-corrosion treatment?

- Yes, aluminum pipes typically require anti-corrosion treatment as aluminum is prone to corrosion when exposed to certain environments or substances.

- Q: Seamless tubes and welded aluminum performance is what is the difference between

- In the case of aluminum tubes of the same material:1, seamless aluminum pipe can be used for fluid parts, such as: water stamping, air, hydraulic, machining, grinding and other important parts.

Send your message to us

Aluminum Pipe Air Cylinder Shell

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords