Aluminum Perforated Sheets - Aluminium PE Power Coating Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium PE Prower Coating Coil Specialised in Construction field Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of theAluminium PE Prower Coating Coil Specialised in Construction field:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

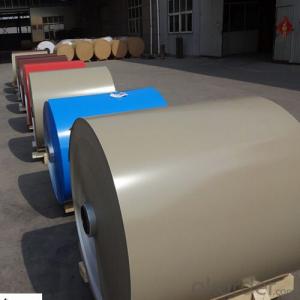

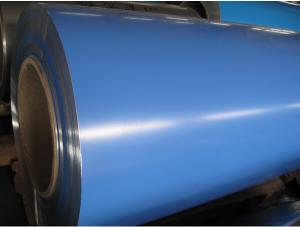

Images of the Aluminium PE Prower Coating Coil Specialised in Construction field:

Aluminium PE Prower Coating Coil Specialised in Construction field Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium PE Prower Coating Coil Specialised in Construction field:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Are aluminum sheets suitable for beverage cans?

- Yes, aluminum sheets are suitable for beverage cans. Aluminum is lightweight, resistant to corrosion, and can be easily shaped into cans. It also provides a protective barrier against light and air, ensuring the quality and freshness of the beverages inside.

- Q: need help choosing an aluminum welder at a descent price also

- What okorder /

- Q: I'm wanting to buy colorguard poles, and I found some good deals on aluminum and fiberglass ones. But what are the pros and cons of each one?

- I'd say fiberglass because... - Durability - Aluminum is a very bendable metal. It dents, it bends, and it breaks easier than any other metal pole you'll find. This is because it's a very low density metal. - Flexibility = more dramatic twirling due to pole flex, and it's less breakable. - Counter Weight = A flag on one side of the pole would be harder to move around swiftly without a counterweight. Thus a heavier pole would entail having a center of gravity on the flag pole closer to the hand, making it easier to maneuver the flag, but the pole would be harder to lift as a whole. I'm no expert on colorguard poles, though. Fiberglass has come a long way. While aluminum is always the same material, fiberglass is a constantly evolving building material.

- Q: What precautions should be taken to ensure safety while installing aluminum sheets?

- <p>When installing aluminum sheets, safety measures include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and hard hats. Ensure the work area is clear of debris and any tripping hazards. Use ladders and scaffolding that are in good condition and set up correctly. Always have a spotter when lifting heavy sheets and use proper lifting techniques to avoid back injuries. Keep hands and feet away from edges and corners to prevent cuts. Ensure all tools are in good working order and use them correctly. Follow all manufacturer's guidelines for installation and adhere to local safety regulations.</p>

- Q: Can aluminum sheets be used for cryogenic applications?

- Aluminum sheets are indeed applicable for cryogenic purposes. Their suitability arises from their commendable thermal conductivity and low density. These qualities enable them to endure exceedingly low temperatures without succumbing to brittleness or compromising their mechanical attributes. Furthermore, aluminum exhibits non-magnetic properties and exceptional resistance to corrosion, rendering it highly significant in cryogenic applications. Nevertheless, it is crucial to meticulously choose the appropriate alloy and thickness of the aluminum sheet, considering the precise cryogenic temperature and intended use, to guarantee optimal performance.

- Q: Are aluminum sheets suitable for use in cryogenic environments?

- Yes, aluminum sheets are suitable for use in cryogenic environments. Aluminum has excellent thermal conductivity, low density, and good mechanical properties at low temperatures, making it an ideal choice for applications in cryogenic environments. Additionally, aluminum has a low coefficient of thermal expansion, which allows it to maintain its structural integrity even under extreme temperature fluctuations.

- Q: Can aluminum sheets be laser cut?

- Indeed, it is possible to laser cut aluminum sheets. Laser cutting is widely favored for its remarkable accuracy and efficiency when it comes to cutting aluminum sheets. This cutting technique entails employing a high-powered laser to either melt or vaporize the material, resulting in a precise and neat cut. Due to its high reflectivity, aluminum necessitates a laser with greater power to effectively penetrate through it. Nevertheless, once the appropriate laser parameters are established, laser cutting machines can easily and precisely cut aluminum sheets. This method finds extensive application in industries such as automotive, aerospace, and manufacturing, where aluminum sheets are utilized for various purposes.

- Q: Is it feasible to use aluminum sheets for constructing exteriors of buildings in regions susceptible to earthquakes?

- <p>Aluminum sheets can be used for building exteriors in earthquake-prone areas, but they must be properly engineered and installed. Aluminum is lightweight and flexible, which can be advantageous in withstanding seismic forces. However, it's crucial to ensure that the aluminum is reinforced with a robust structural system that can distribute the forces during an earthquake. The design must also comply with local building codes and seismic regulations. It's recommended to consult with structural engineers and architects experienced in earthquake-resistant design to ensure the safety and durability of the construction.</p>

- Q: Can aluminum sheets be used for insulation purposes?

- Yes, aluminum sheets can be used for insulation purposes. They have a low thermal conductivity and can effectively reflect heat and cold, making them suitable for insulating applications in various industries such as construction, automotive, and packaging.

- Q: So I want to solder aluminum cans together for this project I have. What tools will I need?

- The only way you can solder any kind of alum. is to gold plate both pieces of whatever you are trying to solder together

Send your message to us

Aluminum Perforated Sheets - Aluminium PE Power Coating Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords