Aluminum F Molding Extrusion Powder Coating Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

POWDER COATING ALUMINUM PROFILE

Industrial aluminium profile

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

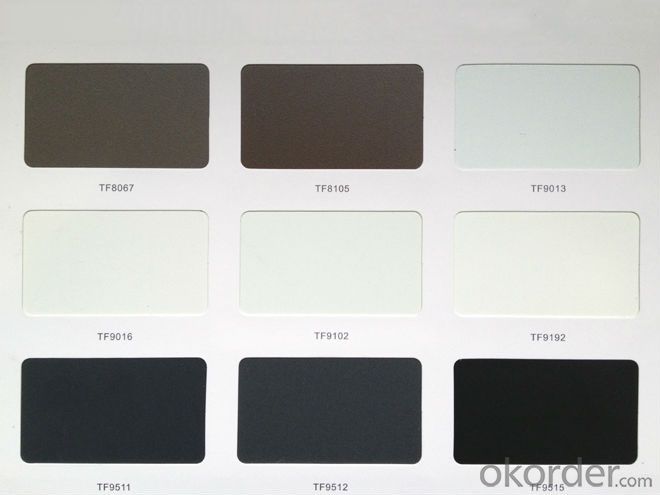

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

- Q: How do aluminum profiles perform in terms of heat resistance?

- Aluminum profiles generally exhibit good heat resistance. Aluminum has a high thermal conductivity, allowing it to efficiently dissipate heat. Additionally, aluminum profiles can withstand high temperatures without deforming or losing structural integrity. However, extreme temperatures, especially above 600°C, can cause aluminum to gradually lose strength. Therefore, it is important to consider the specific application and temperature requirements when evaluating the heat resistance of aluminum profiles.

- Q: Can aluminum profiles be an alternative to steel or other materials?

- Yes, aluminum profiles can be a viable alternative to steel or other materials in many applications. Aluminum profiles offer several advantages over steel, such as being lightweight, corrosion-resistant, and highly durable. One of the key benefits of aluminum profiles is their low weight. Aluminum is approximately one-third the weight of steel, making it an ideal choice when weight reduction is a priority. This lightweight nature makes aluminum profiles easier to handle, transport, and install, reducing overall costs and labor requirements. Additionally, aluminum profiles possess excellent corrosion resistance properties, especially when compared to steel. Aluminum naturally forms a protective oxide layer when exposed to air, which prevents further oxidation and corrosion. This makes aluminum profiles suitable for applications in industries such as construction, automotive, aerospace, and marine, where exposure to moisture, saltwater, or harsh weather conditions is common. Another advantage of aluminum profiles is their high strength-to-weight ratio. Aluminum alloys can be engineered to provide exceptional strength while still being lightweight. This makes them an excellent choice for structural applications where both strength and weight reduction are crucial. Furthermore, aluminum profiles are highly durable and can withstand extreme temperatures. Aluminum has a melting point of 660 degrees Celsius, significantly higher than most other non-ferrous metals. This makes it suitable for applications where exposure to high temperatures or thermal stress is expected. Aluminum profiles can also be easily fabricated, allowing for complex shapes and designs. They can be extruded, machined, welded, or formed into various configurations to meet specific requirements. This flexibility in manufacturing processes makes aluminum profiles a versatile material choice. However, it is important to note that aluminum profiles may not be suitable for all applications. Steel still offers superior strength and rigidity, making it more appropriate for heavy-duty applications or areas where high impact resistance is required. Additionally, aluminum profiles can be more expensive compared to steel, depending on the specific alloy and manufacturing processes involved. In conclusion, aluminum profiles can serve as a viable alternative to steel or other materials in many applications. Their lightweight nature, corrosion resistance, high strength-to-weight ratio, durability, and ease of fabrication make them an attractive choice for various industries. However, the specific requirements of each application should be carefully considered before deciding on the most suitable material.

- Q: Hangzhou aluminum how much money one meter, where can wholesale?

- Decoration materials market, your question is too general profile a variety of non-standard standard and non-standard decoration for many non-standard to open mold and MOQ is non-standard aluminum ingot processing fee plus 5000 yuan I hope to help you. Thank you!

- Q: Are aluminum profiles suitable for use in exterior insulation systems?

- <p>Yes, aluminum profiles can be used for exterior insulation systems. They offer high strength, durability, and resistance to weathering, making them ideal for external applications. Aluminum profiles are lightweight, easy to install, and can be used to create a robust framework for insulating materials, enhancing the energy efficiency and thermal performance of buildings.</p>

- Q: Are aluminum profiles suitable for use in the electronics industry?

- The electronics industry finds aluminum profiles to be a suitable option. Aluminum, being lightweight, durable, and resistant to corrosion, becomes an excellent choice for different electronic applications. Its exceptional thermal conductivity facilitates efficient dissipation of heat in electronic devices, which is crucial to avoid overheating and ensure optimal performance. Moreover, aluminum profiles can be easily customized and fabricated to fulfill specific design requirements, making them adaptable for various electronic components and enclosures. They also possess electromagnetic shielding properties, safeguarding sensitive electronic circuits from interference. All in all, aluminum profiles provide numerous advantages for the electronics industry, making them a popular and appropriate option for electronic devices and equipment.

- Q: Shanghai industrial aluminum profile manufacturers which is better?

- Third: in production of aluminium supplierExplain as follows: in the production of aluminum suppliers, are generally engaged in this industry for more than 10 years, and their users have very rich experience, have a good understanding and knowledge of the quality and performance of products, suitable for the requirement of the customers will recommend price is a good product, choose a convenient and practical accessories.

- Q: What are the bending radii for different aluminum profiles?

- The bending radii for different aluminum profiles can vary depending on the specific profile shape and thickness. It is important to consult the manufacturer's specifications or engineering guidelines to determine the recommended bending radii for each aluminum profile.

- Q: What are the different surface treatment options available for aluminum profiles?

- Aluminum profiles offer a range of surface treatment options, each with its own advantages that enhance both appearance and performance. Let's explore some common treatments for aluminum profiles: 1. Anodizing: A widely used method, anodizing forms a protective oxide layer on the aluminum surface. This treatment provides excellent corrosion resistance, durability, and allows for a variety of color options. Architects, automotive manufacturers, and aerospace industries often rely on anodized aluminum profiles. 2. Powder coating: By applying a dry powder to the aluminum surface and curing it with heat, powder coating creates a tough and decorative layer. This treatment enhances durability, scratch resistance, and weatherability. The construction industry favors powder-coated aluminum profiles due to their appealing aesthetics and resistance to fading. 3. Electrophoretic coating: Also known as electrocoating or e-coating, this process immerses the aluminum profile in a paint bath while applying an electric current to evenly deposit paint particles. Electrophoretic coating offers excellent corrosion resistance, uniform thickness, and a smooth finish. It is commonly used in automotive and electronics manufacturing. 4. Mechanical finishing: To enhance appearance and smoothness, mechanical finishing techniques like brushing or polishing are employed. Brushing creates a brushed or satin finish, while polishing yields a mirror-like reflective surface. These finishes are often applied to decorative or architectural aluminum profiles. 5. Chemical etching: By selectively removing material using acid or a chemical solution, chemical etching can create decorative patterns, logos, or text on the aluminum surface. Various industries utilize chemical etching for branding or aesthetic purposes. 6. Plating: Plating involves depositing a thin layer of metal, such as chrome or nickel, onto the aluminum surface. This treatment enhances appearance, corrosion resistance, and wear resistance. Automotive, electronics, and decorative industries often make use of plated aluminum profiles. It's important to note that the choice of surface treatment depends on specific application requirements, such as aesthetics, durability, corrosion resistance, or conductivity. Consulting with professionals or suppliers can help determine the most suitable treatment option for aluminum profiles based on individual needs.

- Q: Are aluminum profiles suitable for conveyor systems?

- Yes, aluminum profiles are suitable for conveyor systems. Aluminum is a lightweight and durable material that is commonly used in various industries for its numerous advantages. Firstly, aluminum profiles offer excellent strength-to-weight ratio, making them ideal for conveyor systems. They can support heavy loads while still being lightweight, allowing for easy installation and flexibility in design. This characteristic is particularly advantageous in conveyor systems where efficiency and ease of movement are crucial. Secondly, aluminum profiles are corrosion resistant. Unlike other metals, aluminum does not rust, ensuring the longevity and reliability of the conveyor system. This is especially important in industries that deal with moisture or harsh environments. Moreover, aluminum profiles are highly customizable. They can be easily machined and shaped to meet specific requirements and dimensions of the conveyor system. This allows for the creation of unique and efficient designs, ensuring optimal performance and functionality. Additionally, aluminum profiles have excellent thermal conductivity. They quickly dissipate heat, preventing any potential damage or overheating of the conveyor system. This is particularly beneficial in industries that involve high-temperature processes. Furthermore, aluminum profiles are cost-effective. While the initial investment may be slightly higher compared to other materials, the long-term benefits outweigh the costs. Aluminum requires minimal maintenance, reducing downtime and associated expenses. In conclusion, aluminum profiles are indeed suitable for conveyor systems. Their lightweight nature, corrosion resistance, customization options, thermal conductivity, and cost-effectiveness make them an ideal choice for a wide range of conveyor applications.

- Q: Are aluminum profiles suitable for use in aerospace structural components?

- Yes, aluminum profiles are suitable for use in aerospace structural components. Aluminum is a lightweight and strong material, making it an ideal choice for aerospace applications where weight reduction is crucial. It offers high strength-to-weight ratio, excellent corrosion resistance, and good formability, allowing for the fabrication of complex shapes and structures. Additionally, aluminum profiles can be easily joined using various techniques such as welding, riveting, or adhesive bonding, making them versatile for the assembly of aerospace structural components. Overall, the combination of its properties and ease of manufacturing make aluminum profiles a suitable choice for use in aerospace structural components.

Send your message to us

Aluminum F Molding Extrusion Powder Coating Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords