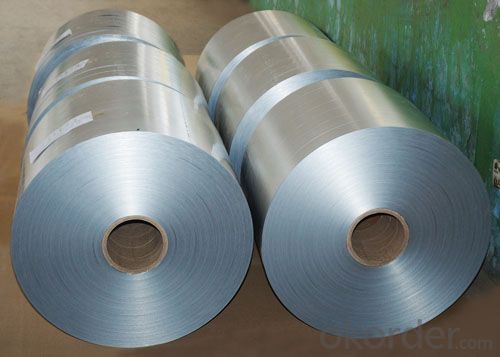

Aluminum Coil Home Depot Lowe's 0.3mm-4.0mm 1100 H14 Aluminium Hardness Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Grade:

1000 Series,7000 Series,3000 Series

Surface Treatment:

Coated,Embossed,Anodized,Mill Finish,Color Coated,Oxidized,Enameled Wire

Shape:

Angle,T-Profile,Flat,Rectangular

Temper:

O-H112,T351-T851,Half Hard

Application:

Decorations,Transportation Tools,Glass Wall,Kitchen Use

Technique:

DC/CC

Thickness:

0.05-4.0mm

Width:

900--1500mm

Outer Diameter:

450-600

Net Weight (kg):

2.5 ton

Packaging:

Wooden pallets

0.3mm-4.0mm 1100 H14 Aluminium Hardness Coils

Packaging & Delivery

Product Specification | |

Grade | 1000 Series: 1050 1060 1100 3000 Series: 3003 3004 3105 5000 Series: 5052 5605,5083 6000 Series: 6061 6063 8000 Series: 8011 8021 8079 |

Thickness | 0.20-8.00mm |

Width | 2400mm max. |

Grade | 1000,3000,5000,6000,8000series |

Coil ID | 75mm, 150mm, 200mm, 300mm, 400mm, 508mm or negotiable |

Coil weight | 1000-5000kgs |

Coil OD | 1700mm max. |

Temper | O, H12, H14, H16, H111, H22 ,H24, H26, H28,T4, T6,etc. |

| Temper | |

| F | processing state |

| H | strain hardening state |

| O | annealing |

| T | heat treatment state |

| H112 | pure state of strain hardening, adjustment has been made to degree of strain hardening and annealing |

| T4 | solid solution treatment and natural efficiency to achieve sufficient stability condition |

| T5 | artificial aging condition of the reentry after high temperature thermal cooling |

| T6 | artificial aging state after solid solution treatment |

Chemical Composition | |||||||||

| Grade | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Al |

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | - | - | 0.05 | 99.5 |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | - | 0.05 | 99.6 |

| 1070 | 0.2 | 0.25 | 0.04 | 0.03 | 0.03 | - | - | 0.04 | 99.7 |

| 1100 | Si+Fe:0.95 | 0.05-0.2 | 0.05 | - | - | 0.1 | - | 99 | |

| 1200 | Si+Fe:1.00 | 0.05 | 0.05 | - | - | 0.1 | 0.05 | 99 | |

| 1235 | Si+Fe:0.65 | 0.05 | 0.05 | 0.05 | - | 0.1 | 0.06 | 99.35 | |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | - | 0.1 | remains |

| 3004 | 0.3 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | - | - | 0.25 | remains |

| 3005 | 0.6 | 0.7 | 0.25 | 1.0-1.5 | 0.20-0.6 | 0.1 | - | 0.25 | remains |

| 3105 | 0.6 | 0.7 | 0.3 | 0.30-0.8 | 0.20-0.8 | 0.2 | - | 0.4 | remains |

| 3A21 | 0.6 | 0.7 | 0.2 | 1.0-1.6 | 0.05 | - | - | 0.1 | remains |

| 5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.50-1.1 | 0.1 | - | 0.25 | remains |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | - | 0.1 | remains |

| 5083 | 0.4 | 0.4 | 0.1 | 0.40-1.0 | 4.0-4.9 | 0.05-0.25 | - | 0.25 | remains |

| 5154 | 0.25 | 0.4 | 0.1 | 0.1 | 3.1-3.9 | 0.15-0.35 | - | 0.2 | remains |

| 5182 | 0.2 | 0.35 | 0.15 | 0.20-0.50 | 4.0-5.0 | 0.1 | - | 0.25 | remains |

| 5251 | 0.4 | 0.5 | 0.15 | 0.1-0.5 | 1.7-2.4 | 0.15 | - | 0.15 | remains |

| 5754 | 0.4 | 0.4 | 0.1 | 0.5 | 2.6-3.6 | 0.3 | - | 0.2 | remains |

| 6061 | 0.40-0.8 | 0.7 | 0.15-0.40 | 0.15 | 0.8-1.2 | 0.04-0.35 | - | 0.25 | remains |

| 6063 | 0.20-0.6 | 0.35 | 0.1 | 0.1 | 0.45-0.9 | 0.1 | - | 0.1 | remains |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.40-1.0 | 0.6-1.2 | 0.25 | - | 0.2 | remains |

| 6A02 | 0.50-1.2 | 0.5 | 0.20-0.6 | Or Cr0.15-0.35 | 0.45-0.9 | - | - | 0.2 | remains |

| 8011 | 0.50-0.9 | 0.6-1.0 | 0.1 | 0.2 | 0.05 | 0.05 | - | 0.1 | remains |

- Q: Can aluminum coils be used in the production of aluminum siding?

- Aluminum siding production can indeed utilize aluminum coils. The manufacturing process of aluminum siding frequently incorporates aluminum coils due to their robustness, lightweight composition, and resistance to corrosion. Typically, these coils undergo processing via a coil coating line, where they receive a protective layer to enhance both functionality and visual appeal. After coating, the aluminum coils are shaped and molded into the desired siding panels, which can subsequently be employed in residential or commercial structures. Aluminum siding is highly favored for its minimal upkeep needs, long lifespan, and capacity to endure diverse weather conditions.

- Q: What are the different coil slitting widths available for aluminum coils?

- The different coil slitting widths available for aluminum coils vary depending on the specific requirements and industry standards. Generally, aluminum coils can be slit into various widths ranging from as narrow as 0.5 inches to as wide as 72 inches or even wider. The exact range of available coil slitting widths is determined by the equipment and capabilities of the coil slitting facility. These coil slitting widths cater to different applications and industries such as automotive, construction, packaging, and electronics. Some common coil slitting widths for aluminum coils include 12 inches, 24 inches, 36 inches, and 48 inches. However, it is important to note that custom slitting widths can also be requested to suit unique project needs.

- Q: Are there any health concerns associated with aluminum coils?

- Yes, there are some health concerns associated with aluminum coils. Aluminum coils used in heating and cooling systems can release small amounts of aluminum particles into the air, which can be inhaled. Prolonged exposure to high levels of aluminum particles may potentially have negative effects on respiratory health and could contribute to the development of lung diseases. However, the health risks are generally low and depend on various factors such as the duration and intensity of exposure. Regular maintenance and cleaning of the coils can help minimize any potential health concerns. It is advisable to consult with HVAC professionals or medical experts for specific concerns or recommendations.

- Q: Is it possible to use aluminum coils for storage purposes?

- <p>Yes, aluminum coils can be used for storage, particularly for certain applications. They are often used in HVAC systems and electrical wiring due to their conductivity and flexibility. For general storage, aluminum coils may be suitable for winding and storing cables, wires, or similar materials. However, for storing items that require a specific environment or have weight concerns, it's important to consider the coil's strength and whether it can provide the necessary support and protection. Always ensure that the storage method complies with safety standards and the material's properties.</p>

- Q: what properties etc makes us use aluminium as the material behind cans...And why does it have the properties?

- Aluminium only became popular in the sixties. Prior to that it was steel cans. You had to have a church key to open them. Aluminium is cheaper to recycle and make than steel. It always comes down to money and costs.

- Q: Are aluminum coils applicable in the manufacturing process of automobiles?

- <p>Yes, aluminum coils are widely used in automobile manufacturing. They are utilized in various components such as engine parts, body panels, and wheels due to their lightweight, corrosion resistance, and strength. Aluminum's recyclability and energy efficiency also make it an environmentally friendly choice for the automotive industry.</p>

- Q: How much cube is the 0.9mm aluminum rolling?

- This is a common problem. Anyone who had received high school education can calculate it very quickily. One way is to calculate sectional area with circular area, then times the thickness of the aluminum rolling. Another way is to use the outer diameter circular area to subtract the core area and then times the thickness of aluminum rolling.

- Q: What is the minimum order quantity for aluminum coils?

- The minimum order quantity for aluminum coils may differ based on the supplier and specific product requirements. Certain suppliers may set a minimum order quantity of one coil, whereas others may mandate several coils or even a full container load. To determine the minimum order quantity for aluminum coils, it is advisable to directly reach out to the supplier or manufacturer, as it can vary.

- Q: I want to roll aluminum rolls and operate the machine for more than three years

- (3) the suspension with pay during the period of nursing by the unit responsible during the period of hospitalization; (4) the food allowance according to the standard issued by injured workers

- Q: What is the typical lifespan of an aluminum coil?

- Factors such as usage, maintenance, and environmental conditions can cause the typical lifespan of an aluminum coil to vary. However, if an aluminum coil is properly cared for and regularly maintained, it can last for 20 to 30 years or even longer. It is possible to extend this lifespan by keeping the coil clean, ensuring proper ventilation to prevent moisture buildup, and promptly addressing any damages or issues. Moreover, the lifespan of an aluminum coil can also be affected by exposure to harsh weather conditions, chemicals, or corrosive environments. Therefore, it is important to seek guidance from manufacturers or industry professionals to obtain specific information about the expected lifespan of a particular aluminum coil in various applications.

Send your message to us

Aluminum Coil Home Depot Lowe's 0.3mm-4.0mm 1100 H14 Aluminium Hardness Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords