Us Aluminum Coil Company Capf3137bcaa Aluminum Coil 3003 H14 for Air Conditioning Condensers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

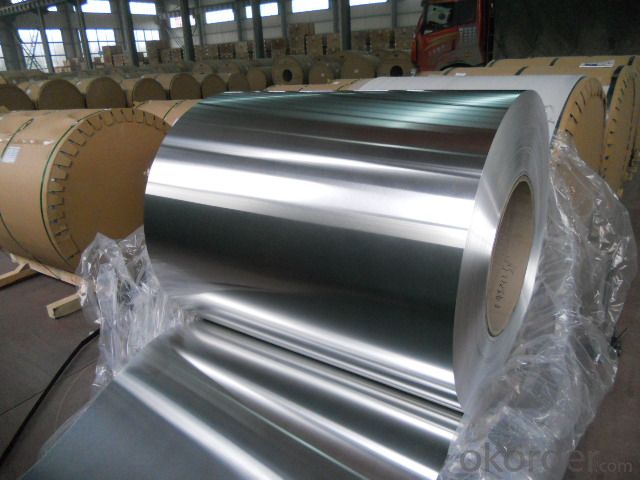

Aluminum Coil 3003 H14 for Air Conditioning Condensers

l Product Introduction

Aluminium Coil is widely used in manufacturing aluminum thin sheet and aluminum foil. It is suitable for further machining with original standard quality. It is easy to be controlled and be manufactured to according to requirements.

l Product Specification

Grade: 3000 series

Alloy or not : Alloy

Thickness :0.15-3.0mm

Width:7.5-2000mm

Place of origin: Jiangsu province ,China mainland

Certificate: ISO9001:2008 ISO14001:2004 ,MSDS ,SGS ,Mill test ,GB/T3880-2006

Typical Chemistry:

Cu: 0.20

Si: 0.60

Fe: 0.70

Mn: 1.0/1.5

Zn: 0.10

Aluminum: Balance

Characteristics: The 3003 alloy is non-heat-treatable, its corrosion resistance and formability are excellent, but its anodizing characteristics are rated as fair.

Mechanical Properties:

Tensile Strength: 110-205

Yield Srength: 40-190

Elongation: 30-4

Brinell Hardness: 28-47

Typical Application:

3003 is often used in general sheet metal work, stamped, spun and drawn parts, cabinets, mail boxes, food and chemical storage and handling. If part is to be anodized consider 5005, if higher strength is desired consider 5052.

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advanced payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium coil is one of the popular product in the market of CNBM. With advanced technology and equipment, CNBM has sold its hight quality color coated aluminium coil to the world.

l CNBM World Wide

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: Can aluminum coils be used for signage and display applications?

- Yes, aluminum coils can be used for signage and display applications. Aluminum is a versatile material that is lightweight, durable, and resistant to corrosion, making it an ideal choice for various signage and display purposes. Its flexibility allows for easy shaping and customization, while its smooth surface provides a perfect canvas for printing graphics and designs. Additionally, aluminum coils can be easily mounted, making them suitable for both indoor and outdoor signage and displays.

- Q: The user is asking if there are any recycling programs specifically for aluminum coil in their country.

- <p>Yes, many countries have recycling programs for aluminum coil. These programs aim to collect and recycle aluminum coils to reduce waste and conserve resources. The availability and specifics of these programs can vary by country, so it's best to check with local waste management authorities or recycling centers for information on programs in your area. Some countries also have legislation mandating recycling of certain materials, including aluminum, to encourage participation and reduce environmental impact.</p>

- Q: How do aluminum coils contribute to lightweight construction?

- Due to its properties as a metal, aluminum plays a crucial role in lightweight construction. Its low density sets it apart from other metals like steel or copper, making it significantly lighter. When formed into coils, aluminum increases its surface area, resulting in more efficient heat transfer and distribution. The utilization of aluminum coils in various industries such as automotive, aerospace, and construction leads to a notable reduction in overall weight. This reduction offers several advantages, including enhanced fuel efficiency in vehicles, increased payload capacity in aircraft, and easier handling and installation in construction projects. Furthermore, the lightweight nature of aluminum coils enables designers and engineers to develop more innovative and energy-efficient designs. With less weight to support, thinner and lighter materials can be used for other components, resulting in additional weight savings. This not only saves costs during manufacturing and transportation but also reduces environmental impact. Moreover, aluminum coils possess excellent corrosion resistance, making them ideal for outdoor applications. Their ability to resist rust and corrosion adds to their durability and longevity, ensuring that lightweight structures made with aluminum coils can withstand harsh environmental conditions. In conclusion, aluminum coils contribute significantly to lightweight construction by providing a durable and lightweight material. This enables designers and engineers to create more efficient and sustainable structures, vehicles, and products. The use of aluminum coils not only reduces the weight of the overall construction but also offers benefits such as improved fuel efficiency, increased payload capacity, and cost savings.

- Q: I heard that one pound of aluminum pop tabs are worth more then a pound of aluminum pop cans. Is this true? Thank you.

- The pop tabs do not have the plastic, or the paint, just pure aluminum. ~Garnet Permaculture homesteading/farming over 20 years

- Q: I was wandering, if your spear's shaft is made of aluminum, does that have any strength to it, i mean, say you had to block with the shaft, would a weapon break through like your basic sword or basic axe, i don't mean big heavy swords and axes, but like average ones, could it break through an aluminum shaft of a spear?

- How thick is the shaft? Even if it is solid, if it is fairly thin in order to be light weight like competition weapons I would not bet my life on blocking with something like that. If your shaft is solid and maybe one to 1 1/2 inches thick then maybe. A weapon does not have to be heavy to be powerful. If the practitioner is strong and fast he can generate quite a bit of power even with a lighter weight weapon. A bokken is not very heavy at all but in the hands of a skilled practitioner it can generate enough force to kill. The effectiveness of a weapon is in the technique not the weight. So don't underestimate a weapon and let weight fool you.

- Q: Is it possible to customize the dimensions of aluminum coils?

- Indeed, the dimensions of aluminum coils can be tailored to suit individual preferences. Customers are able to request and obtain aluminum coils that have been manufactured and trimmed to specific measurements in accordance with their particular requirements and specifications. This customization procedure entails the meticulous cutting and molding of the aluminum coil in order to achieve the desired dimensions. This capability offers versatility across a range of industries and applications, where precise coil sizes are indispensable. By customizing the dimensions of aluminum coils, they become perfectly compatible with various production procedures, machinery, or end-use applications.

- Q: Can aluminum coils be used for heat sinks?

- Indeed, the utilization of aluminum coils as heat sinks is possible. Aluminum stands out as a favored option for heat sinks, thanks to its remarkable thermal conductivity attributes. These heat sinks are specifically engineered to disperse the heat generated by electronic parts, such as processors or power transistors, in order to avert overheating and guarantee optimum performance. By utilizing aluminum coils, heat can be effectively redirected away from the heat source and spread across a broader surface, resulting in efficient heat dissipation. Furthermore, aluminum possesses the advantages of being lightweight, resistant to corrosion, and cost-effective, rendering it an ideal material for heat sink applications.

- Q: What are the different available coil weights for aluminum coils?

- The different available coil weights for aluminum coils can vary depending on the specific manufacturer and application requirements. However, common coil weights for aluminum coils range from a few hundred pounds to several thousand pounds.

- Q: Can aluminum coils be used in the production of electrical transformers?

- Yes, aluminum coils can be used in the production of electrical transformers. Aluminum coils offer several advantages such as being lighter in weight, having better thermal conductivity, and being more cost-effective compared to traditional copper coils.

- Q: What are the typical delivery methods for aluminum coils?

- The typical delivery methods for aluminum coils vary depending on the size and quantity of the coils being transported. However, there are a few common delivery methods that are often used in the industry. One of the most common methods is by truck. Aluminum coils are usually transported on flatbed trucks, which provide a secure and stable platform for the coils during transit. This method is suitable for both short and long-distance deliveries, and it allows for easy loading and unloading of the coils at the destination. Another common delivery method is by rail. Rail transportation is often used for larger quantities of aluminum coils or when the delivery distance is significant. Rail cars equipped with flatbeds or specialized coil cars are used to transport the coils safely and efficiently. This method is particularly advantageous for long-distance deliveries, as it is generally more cost-effective and environmentally friendly compared to other modes of transportation. In some cases, aluminum coils may also be delivered by sea. This method is typically used for international shipments or when the coils need to be transported over long distances. Coils are usually packed into containers, securing them during the journey and protecting them from any potential damage. Shipping by sea allows for efficient transportation of large quantities of coils, but it may take longer compared to other delivery methods due to customs procedures and port handling. Lastly, smaller quantities of aluminum coils can be delivered by air freight. This method is often used when time is critical or for urgent shipments. Airplanes equipped with cargo holds are used to transport the coils, ensuring their safe and expedited delivery. However, air freight is generally more expensive than other delivery methods, so it is typically reserved for time-sensitive or high-value shipments. Overall, the typical delivery methods for aluminum coils include truck, rail, sea, and air. The selection of the appropriate method depends on various factors such as the size, quantity, distance, urgency, and cost considerations.

Send your message to us

Us Aluminum Coil Company Capf3137bcaa Aluminum Coil 3003 H14 for Air Conditioning Condensers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords