6061 Aluminum Coils for Sale - 1200 Aluminum Alloy Coil H112 Temper

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

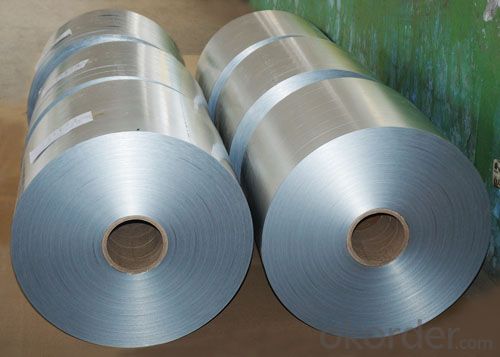

Aluminum Coil 1200 Aluminum Alloy Coil H112 Temper

1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above

3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment.

6xxx series represents 6061 mainly contain magnesium and silicon of two elements, so focused on the 4000 series and the advantages of the 5000 series 6061 is a cold treatment aluminum forging products, apply to fight against corrosion, oxidizing demanding applications.

Description

item | 1050 1060 1100 3003 Aluminum coil | |

Standard | GB/T3190-2008,GB/T3880-2006,ASTM B209,JIS H4000-2006,etc | |

Material | 1060,1050,1100 3003,3103,3004,3005,3105 5052, 5454,5754 | |

Size | Thickness | 0.5mm-3.5mm |

Width | 800-1500mm | |

Weight/Roll | About 1.5MT/3MT | |

Quality control | Mill Test Certificate is supplied with shipment, Third Part Inspection is acceptable. | |

Surface | Bright, polished, hair line, brush, checkered, embossed, etc | |

Trade terms | Price term | ,FOB, CNF, CIF, etc |

Payment Term | TT,L/C | |

MOQ | 2MT | |

20 GP Capacity | About 20-25MT | |

Delivery time | 1.The products will delivery immediately after receiving the payment. 2.According to the order quantity, prompt delivery. | |

Export to | Ireland,Singapore,Indonesia,Ukraine,Spain,Canada,USA,Brazil,Thailand,Korea,Iran,India,Egypt,Kuwait, Oman,Viet Nam, South Africa, Dubai, Russia, etc | |

Package | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | |

Application | 1)Further making utensil.2)Solar reflective film3)The appearance of the building4)Interior decorating:ceilings,walls,etc.5)Furniture cabinets6)Elevator decoraction7)Signs,nameplate,bags making.8)Decoration inside and outside the car9)Household appliances:refrigerators,microwave ovens,audio equipment,etc.10)The consumer electronics:mobile phones,digital cameras,MP3,etc. | |

- Q: What substances are used to make aluminum coils?

- <p>Aluminum coils are made from aluminum, a lightweight and malleable metal with the chemical symbol Al. They are typically produced from high-purity aluminum or aluminum alloys, which may include small amounts of other elements to enhance specific properties such as strength, durability, or resistance to corrosion. Pure aluminum is soft and lacks strength, so alloys are often used to improve these characteristics for various applications.</p>

- Q: Can aluminum coils be used in the production of aluminum foam panels?

- Yes, aluminum coils can be used in the production of aluminum foam panels. The coils are typically processed through a foaming method, such as powder metallurgy or melt route, to create a foam structure. This allows for the production of lightweight and strong aluminum foam panels suitable for various applications, including in the automotive, aerospace, and construction industries.

- Q: Explain the key differences between aluminum coil welding and soldering processes.

- <p>Aluminum coil welding and soldering are two distinct methods used in metal joining. Welding involves the fusion of aluminum coils using heat to create a strong bond between the metals. This process can be done with various techniques such as MIG, TIG, or laser welding, and it results in a permanent joint. Soldering, on the other hand, is a process that uses a filler metal with a lower melting point than the base metal (aluminum in this case) to join the materials. The joint is not as strong as a welded joint, and the process does not involve melting the base metal. Soldering is often used for electrical connections or when a less permanent bond is required. In summary, welding creates a stronger, more permanent bond by melting the base metal, while soldering uses a filler metal to create a less permanent bond.</p>

- Q: Is it possible to determine the spring constant of an aluminum coil using a spring compressor?

- <p>Yes, you can use a spring compressor to measure the spring constant of an aluminum coil. The spring constant (k) can be calculated using Hooke's Law, which states that the force exerted by a spring is proportional to its displacement (F = kx). By applying a known force to the spring and measuring the resulting displacement, you can calculate the spring constant. A spring compressor can apply a controlled force, and a displacement gauge can measure the compression, allowing you to determine the spring constant accurately.</p>

- Q: How are aluminum coils used in the production of furniture?

- Due to their advantageous properties, aluminum coils find wide application in furniture production. Typically composed of high-quality aluminum alloy, these coils possess excellent corrosion resistance, durability, and lightweight characteristics. When it comes to furniture manufacturing, aluminum coils are primarily employed in constructing the framework or structure of the furniture pieces. These coils are often shaped and formed into various profiles to provide the necessary strength and rigidity for the furniture item. Additionally, the coils can be effortlessly bent, cut, and joined together, allowing for the creation of different components such as chair frames, table legs, or cabinet structures. This versatility enables manufacturers to design and produce furniture with intricate and customized shapes and sizes. Furthermore, aluminum coils are highly adaptable to various finishing techniques. They can undergo anodization, painting, or powder coating to enhance their aesthetic appeal and offer additional protection against wear and tear. As a result, furniture made with aluminum coils is resistant to scratches, stains, and fading, ensuring longevity and an appealing appearance. Moreover, aluminum coils provide a lightweight alternative to materials like steel or wood, making furniture easier to transport and handle. This is particularly advantageous for outdoor furniture or pieces that require frequent movement or rearrangement. In addition, aluminum is an environmentally friendly and sustainable material. It is fully recyclable, allowing manufacturers to reduce their carbon footprint and contribute to a more sustainable production process. In conclusion, the inclusion of aluminum coils in furniture production is crucial, as they offer strength, durability, versatility, and aesthetic appeal. Their usage in furniture manufacturing enables the creation of lightweight, customizable, and sustainable furniture pieces that meet the demands of modern consumers.

- Q: How are aluminum coils inspected for quality control?

- Aluminum coils are inspected for quality control through a combination of visual inspections and various non-destructive testing methods. These measures ensure that the coils meet the required specifications and are free from any defects or flaws. Visual inspections involve trained personnel carefully examining the coils for surface defects such as scratches, dents, or any irregularities in shape or size. The inspectors also check for any signs of contamination, oxidation, or discoloration. Any abnormalities detected during this visual inspection are noted and addressed accordingly. In addition to visual inspections, non-destructive testing techniques are employed to evaluate the internal quality of the aluminum coils. One commonly used method is ultrasonic testing, where high-frequency sound waves are transmitted through the coils. The reflected sound waves are analyzed to identify any internal defects like voids, cracks, or delaminations. This technique allows for a thorough assessment of the coil's integrity without causing any damage to the material. Another non-destructive testing method used for quality control is eddy current testing. This technique involves inducing electrical currents in the coils and measuring the resulting magnetic fields. Any variations in the magnetic fields can indicate flaws or defects in the aluminum, such as cracks or inclusions. Eddy current testing is particularly effective in detecting surface defects and discontinuities. Furthermore, measurements of important physical properties like thickness, width, and flatness are taken to ensure they meet the required standards. This is typically done using specialized instruments such as micrometers, calipers, or laser scanners. Overall, the inspection of aluminum coils for quality control involves a combination of visual inspections and non-destructive testing techniques to ensure that the coils are free from defects, meet the required specifications, and are of high quality.

- Q: What are the differences among various types of steel wires and their respective coiling techniques?

- <p>Yes, there are differences between different types of steel wires and their coiling methods. Steel wires can be categorized based on their composition, strength, and use, such as carbon steel, stainless steel, and alloy steel wires. Each type has unique properties that affect their coiling methods. For instance, carbon steel wires are strong and ductile, suitable for standard coiling techniques, while stainless steel wires offer corrosion resistance and may require special handling to prevent damage. The coiling methods also vary; some common ones include spool coiling, loop coiling, and pancake coiling. Each method has specific applications and considerations for wire diameter, tension, and storage. Understanding these differences is crucial for selecting the appropriate wire and coiling technique for a given application.</p>

- Q: Are aluminum coils suitable for low-maintenance applications?

- Yes, aluminum coils are suitable for low-maintenance applications. Aluminum is known for its durability and resistance to corrosion, making it an excellent choice for applications that require minimal upkeep. Unlike other materials, such as steel, aluminum coils do not rust or require regular painting to maintain their appearance. Additionally, aluminum is lightweight, which can make installation and handling easier, especially in low-maintenance applications where frequent maintenance may not be feasible or desirable. Overall, aluminum coils offer a reliable and low-maintenance solution for various applications.

- Q: How much is one ton of aluminum coil?

- The price of aluminum sheet is calculated according to the price of aluminum ingot + processing fee (aluminum plate state), and the specific price is also different according to the size and size of aluminum sheet.If you have any questions, please ask. I hope to help you.

- Q: I am concerned about the environment so I collect empty aluminum cans off the street when I walk my dog. Right now I have 3 large garbage bags full of crushed aluminum can. The problem is... some of the cans have dirt on and in them. Some of thoroughly flattened ones may even have small pebbles embedded in them. Will these be accepted at the recycling facility? I'm guessing it doesn't matter because when they melt them any organic materials will burn away and any dirt particles or small pebbles will be separated from the molten aluminum. What do you think?

- yes they won't care about dirt

Send your message to us

6061 Aluminum Coils for Sale - 1200 Aluminum Alloy Coil H112 Temper

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords