Customized 1060 Aluminum Coil for Window Use and Decoration Strips

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminium Strips for Window Use and Decoration

l Product Specification

Description | 1060 aluminum strips |

Alloy | 1050; 1060; 1070; 1100; 1200; 1235; 3003; 3105; 3A21; 5052; 5754; 5083; 5A02; 5A03; 5A05; 8011 |

Temper | O; H12; H14; H16; H18; H22; H24; H26 |

Thickness (MM) | 0.1~6.0 |

Width (MM) | 20~2300 |

Inner Dia (MM) | 75; 150; 200; 300; 400; 505 |

Application | Construction, Decoration, Automobile, Electronics, Machinery, Boat Construction, Aeronautics&Astronautics, Cookware, Packing etc. |

Chemical Composition GB/T 3190-1996

Aluminum Alloy | Si | Fe | Cu | Mn | Mg | Zn | Ti | Other Composition | Others | Al | |

Per | All | ||||||||||

1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | 0.05 | 0.03 | V0.05 | 0.03 | - | 99.60 |

ALUMINIUM Coils used for celling, decorate, ACP,Curtain Wall,Roofing Sheet, PC base, radiator,cookware,deep drawing and more.

- 1 series Aluminum Coils temper: O-H112

- 1 Series Aluminum Coils Alloy: 1100/1050/1060/1200/1035/1070

-Thickness: 0.5-10mm

-Width:200-2500mm

-Length:12m Max.

l Packaging & Delivery

Packaging detail: Seaworthy Export Standard Wooden Pallet and with damp proof film as first layer, Kraft paper as second layer, Cardboard card as third layer Criss-cross steel strip to fix outside

Delivery detail: About 15 days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

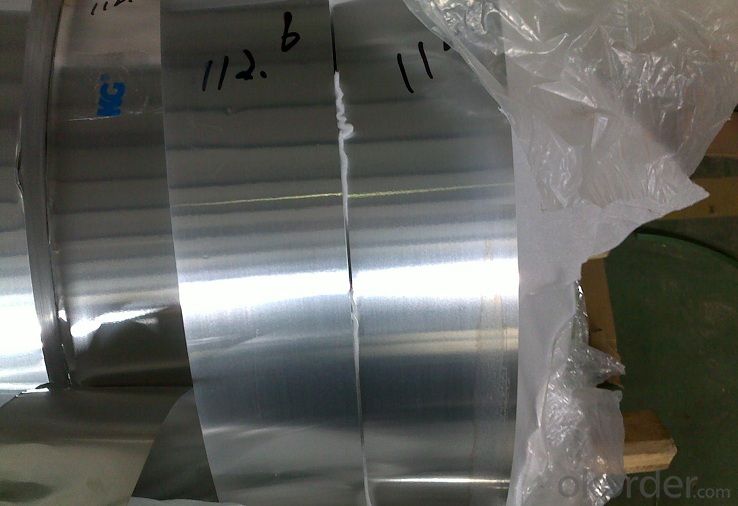

l Products Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: Are aluminum coils suitable for architectural applications?

- Yes, aluminum coils are suitable for architectural applications. Aluminum is a highly versatile and durable material that is commonly used in the construction industry for various architectural applications. Aluminum coils offer several advantages for architectural use, including their lightweight nature, corrosion resistance, and ability to be easily formed into desired shapes and sizes. These coils can be used in architectural applications such as roofing, cladding, facades, and gutters, among others. Additionally, aluminum coils can be coated with different finishes, providing a wide range of aesthetic options for architects and designers. Overall, aluminum coils are an excellent choice for architectural applications due to their strength, durability, and flexibility.

- Q: What are the different color coating options for aluminum coils?

- There are various color coating options available for aluminum coils, depending on the specific requirements and preferences of the customer. Some common color coating options include: 1. Polyester (PE) Coating: This is one of the most popular coating options for aluminum coils. Polyester coatings provide excellent color retention, durability, and resistance to UV radiation, making them suitable for both indoor and outdoor applications. 2. Polyvinylidene Fluoride (PVDF) Coating: PVDF coatings offer superior weather resistance, chemical resistance, and color stability. They are highly durable and can withstand harsh environmental conditions, making them suitable for architectural applications. 3. High-Durability Polyester (HDP) Coating: HDP coatings are specifically formulated to provide enhanced durability and resistance to fading, chalking, and abrasion. They are commonly used in demanding applications where long-term color retention and performance are critical. 4. Silicone Modified Polyester (SMP) Coating: SMP coatings provide good weather resistance, flexibility, and color stability. They are often used in industrial and commercial applications that require a balance between performance and cost-effectiveness. 5. Polyurethane (PU) Coating: PU coatings offer excellent chemical resistance, flexibility, and adhesion properties. They are commonly used in applications that require resistance to chemicals, solvents, and harsh weather conditions. Additionally, various color options are available within each coating type, allowing customers to choose from a wide range of colors and finishes. Some manufacturers also offer custom color matching services to meet specific design requirements. It is important to note that the selection of the appropriate color coating option for aluminum coils should consider factors such as the intended use, environmental conditions, durability requirements, and aesthetic preferences. Consulting with a trusted supplier or coating specialist can help determine the most suitable color coating option for a specific application.

- Q: How are aluminum coils protected from damage during transportation?

- To protect aluminum coils during transportation, a combination of packaging materials and handling precautions is utilized. Initially, the coils are wrapped with materials like stretch film or plastic wrap to prevent scratches and abrasions, thus maintaining the coil's surface integrity and preventing potential damage. Moreover, the coils are typically placed on sturdy wooden pallets or skids, providing a stable base for transportation. This reduces movement and shifting during transit, avoiding dents or deformations in the coils. Additionally, steel or plastic strapping is used to secure the coils, ensuring their stability and preventing unintended unwrapping or unrolling. The straps are tightly fastened around the coils and pallets, creating a secure bundle capable of withstanding jostling and vibrations during transportation. During loading and unloading, specialized equipment like forklifts or cranes is employed to handle the coils carefully, reducing the risk of dropping or mishandling that could result in significant damage. In summary, a combination of protective packaging materials, secure pallets, and careful handling procedures is employed to protect aluminum coils during transportation. These measures aim to preserve the coils' quality and structural integrity, ensuring they reach their destination in optimal condition.

- Q: If you were to make something from each of these.which is more expensive? aluminum or carbon fiber ?which is stronger?What would the advantages or disadvantages of each be?

- Aluminum Vs Carbon Fiber

- Q: How do aluminum coils compare to iron coils in terms of weight?

- In terms of weight, aluminum coils possess a significant advantage over iron coils due to their lower density. This results in aluminum coils weighing less for the same volume. With aluminum weighing approximately one-third of iron, it becomes a substantially lighter material when utilized in coil applications. This advantage in weight proves particularly advantageous in industries prioritizing weight reduction, such as automotive and aerospace, as it enhances fuel efficiency and overall performance.

- Q: who discovered aluminum and in what year did they discover it?

- Aluminum was named for one its most important compounds, alum. Alum is a compound of potassium, aluminum, sulfur, and oxygen. The chemical name is potassium aluminum sulfate, KAl(SO4)2. No one is sure when alum was first used by humans. The ancient Greeks and Romans were familiar with the compound alum. It was mined in early Greece where it was sold to the Turks. The Turks used the compound to make a beautiful dye known as Turkey red. Records indicate that the Romans were using alum as early as the first century B.C. It was first ISOLATED in 1827 by German chemist Friedrich W?hler (1800-82). W?hler used a method perfected by English chemist Sir Humphrey Davy (1778-1829),

- Q: Aluminum is directly below Mg. If aluminum is oxidized so readily, then how can we make planes or ships out of it and they don't fall apart after a few months or years?

- Yes aluminum does oxidize just like any other metal. The difference is that aluminum oxidizes the same color as the metal therefore you cannot tell that is oxidizing. Once is oxidizes a little bit, the oxidize protects the metal and it does not oxidize any more.

- Q: A cube of solid aluminum has a volume of 1.00 m3 at 20°C. What temperature change is required to produce a 130 cm3 increase in the volume of the cube?

- The linear expansivity of aluminum is 23 x10^-6 /K. Bulk expansivity is 3 x 23 x10^-6 / k For 130 [cm^3] the temperature required is 130 [cm] ^3/ 3 x 23 x10^-6 = 0.00013/[3 x 23 x10^-6] = 1.88 K ========================= If each side of the cube of side 1m expands by e, then its new volume = [1+e]^3 = 1 + 3e + 3e^2 +e^3. Neglecting high powers of e as negligible, the increase in volume is 3e. But e = 23 x10^-6 x rise in temperature 3e = 3*23 x10^-6 x rise in temperature. Given 3e = 0.00013 0.00013= 3*23 x10^-6 x rise in temperature Rise in temperature = 0.00013 / 3*23 x10^-6 = 1.88 K

- Q: I have heard that aluminum may be a contributing agent in causing Alzheimer's disease, and that if we drink from aluminum cans, that we get aluminum into our system from them. It seems like this would be pretty easy to test in a laboratory, whether or not there are aluminum particles in the contained beverage. But I have heard or read that the inside of the cans are coated with something. So is this just typical uninformed rumors from the Internets, or is there anything to it? Hate to sound rude, but I am not really interested in opinions, like Well I don't think they would sell them if... or Oh yes, I think you get lots of aluminum from it. I am only interested in facts, not gut feelings or opinions.

- I recently covered this in a materials science class I am taking. My professor is Dr. Han Choo. Most aluminum cans have a coating of epichorohydrin. This is not to keep out the aluminum from the drink, but rather it is meant to keep the drink from reacting with the can(many sodas can actually eat through metal). The reaction of the soda with the can ruins the taste which is obviously something soda companies do not want. Aluminum also does not cause Alzheimer's. The metal is considered poisonous in large quantities and the FDA restricts the amount that can be added to drugs, food, drink, etc., but scientific consensus states that there is no link between Alzheimer's disease and aluminum. As far as BPA(Bisphenol A) health concerns go, there is little evidence proving any real harm to adults. The problems are only seen in offspring of the rodents being tested with BPA. For the most part there is little concern about the negative results of BPA exposure. There has not been any clear links in humans yet either. Extensive testing is still being done and BPA might be marginally dangerous to infants, but I wouldn't worry about it too much. If you still wish to guard yourself against BPA you should be aware that BPA is used in almost all commercial plastics and can liners(bottles, canned food, food storage containers, etc.) not just in aluminum cans.

Send your message to us

Customized 1060 Aluminum Coil for Window Use and Decoration Strips

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords