China Color Coated Aluminum Coil - Aluminium Profile Glass Wall Usage with Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Profile Glass Wall Usage and Best Quality Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminium Profile Glass Wall Usage and Best Quality:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

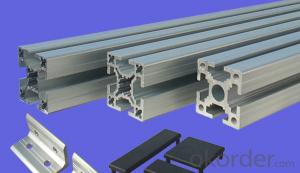

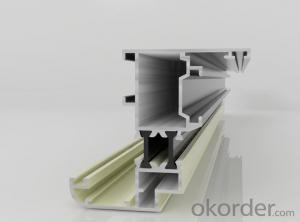

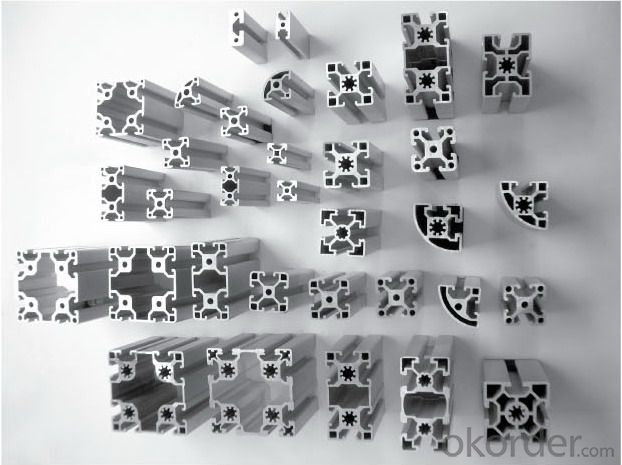

Images of the Aluminium Profile Glass Wall Usage and Best Quality:

Aluminium Profile Glass Wall Usage and Best Quality Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: What are the different coil diameters available for aluminum coils?

- The coil diameters available for aluminum coils can vary depending on the specific requirements and applications. Generally, aluminum coils are available in a range of diameters to suit different needs. These diameters can range from as small as a few inches to as large as several feet. The exact coil diameter options can differ between manufacturers and suppliers. It is important to note that the chosen diameter will impact factors such as coil weight, handling, and compatibility with specific machinery or equipment. Therefore, it is advisable to consult with suppliers or manufacturers to determine the specific coil diameter options available for aluminum coils based on the intended use and requirements.

- Q: What is the price range of aluminum coils?

- Aluminum coil prices can fluctuate depending on a range of factors including thickness, width, alloy type, and market conditions. Typically, the price range for aluminum coils can begin at $1 per pound for thinner gauge coils and can rise to $3 per pound or more for thicker gauge coils or specific alloys. It is crucial to understand that these prices are estimated and subject to change based on market demand, availability, and other economic influences. To obtain accurate and current pricing information, it is advised to reach out to suppliers or refer to market research reports.

- Q: Is it safe and effective to use an oven to heat an aluminum coil?

- <p>Yes, you can use an oven to heat an aluminum coil, but with caution. Aluminum has a high melting point and can withstand high temperatures, making it suitable for heating in an oven. However, it's crucial to ensure that the coil is clean and free of any non-stick coatings or residues that could produce toxic fumes when heated. Additionally, monitor the temperature and duration of heating to avoid overheating, which might cause the coil to warp or degrade. Always follow safety guidelines and manufacturer's instructions for your specific oven and aluminum coil.</p>

- Q: How are aluminum coils used in the production of automotive heat shields?

- Aluminum coils are used in the production of automotive heat shields as they provide excellent thermal conductivity and heat dissipation properties. These coils are shaped into specific patterns or designs and then attached to the heat shields to effectively reflect and reduce the transfer of heat from the engine or exhaust system to other sensitive components in the vehicle. The use of aluminum coils in heat shields helps in maintaining optimal operating temperatures, enhancing overall performance, and preventing potential damage or fire hazards.

- Q: What is the reason for the grooves that go around the circumference of a tin/aluminium can? It can't be for grip because they're covered with paper anyway and i don't think it would make much difference.

- This is the correct answer. This is a Microsoft Interview Question Source: How Would You Move Mount Fuji?: Microsoft's Cult of the Puzzle -- How the World's Smartest Companies Select the Most Creative Thinkers There was a time when cans were in rectangular shape and made of heavy steel. As can companies became more cost and environment conscious, they figured out ways to switch to thinner aluminum cans. The thin aluminum is less strong. Like eggshells, today's cans are just about as thin as they can be and still reliably enclose their contents. This demands architectural tricks that weren't necessary with the steel cans. The thickest and strongest part of the can is the top, attached separately with a crimp. The top has to stand the stress of someone ripping open the flip top. Because the top is thicker metal, the manufacturers found it desirable to minimize its diameter. So they shrunk the top a little. This meant adding a bevel at the top to connect it to the rest of the can. (They couldn't shrink the diameter of the whole can, or it would hold less beer.) Once you shrink the top, you also have to shrink the bottom, for the cans are supposed to stack. Both top and bottom are tapered. There are other reasons why thebottom is tapered. The bottom and middle are pressed from a single piece of thin aluminum, eliminating the extra step of attaching a separate bottom to the can. This is easiest to do when there is a bevel rather than a sharp right angle. The bevel also makes the can a little more dent-proof at the ends. You could get a similar strengthening effect with a convex bottom, but then the cans wouldn't stack.

- Q: Are aluminum coils suitable for high-temperature applications?

- No, aluminum coils are not suitable for high-temperature applications as they have a low melting point and can deform or degrade at elevated temperatures.

- Q: Is there any legislation or regulation governing the use of aluminum coils within specific industrial sectors?

- <p>Yes, there are regulations on using aluminum coils in certain industries. These regulations often vary by country and industry. For instance, in the food and beverage industry, aluminum coils may be subject to food safety standards to ensure they do not contaminate products. In construction, they might need to meet building codes and specifications for strength and durability. The aerospace industry has stringent regulations regarding the materials used in aircraft parts, including aluminum coils. Compliance with these regulations is crucial to ensure safety, quality, and to avoid legal penalties.</p>

- Q: Can aluminum coils be used in solar panel systems?

- Yes, aluminum coils can be used in solar panel systems. Aluminum is a commonly used material in solar panel manufacturing due to its lightweight, corrosion resistance, and high thermal conductivity properties. It is often used as a backing material for solar cells and as a component in the frame or structure of the solar panel.

- Q: What are the standard sizes of aluminum coils?

- The standard sizes of aluminum coils can vary depending on the specific industry and application. However, there are a few common standard sizes that are widely used. For general industrial applications, the standard width of aluminum coils ranges from 36 inches to 72 inches. The thickness of these coils typically varies between 0.018 inches to 0.125 inches. The length of the coils can vary, but it is commonly around 1,000 feet or more. In the construction industry, the standard sizes of aluminum coils can be different. The width can range from 24 inches to 48 inches, and the thickness can be between 0.019 inches to 0.032 inches. The length of these coils can also vary depending on the specific project requirements. It is important to note that these sizes are just general guidelines and can vary depending on the specific manufacturer, industry requirements, and customer preferences. It is always recommended to consult with the manufacturer or supplier to determine the exact standard sizes available for aluminum coils in your specific industry.

- Q: Can aluminum coils be used for magnetic purposes?

- Aluminum coils, unfortunately, cannot serve magnetic purposes. Being a non-magnetic material, aluminum lacks any magnetic properties. To harness the magnetic potential of coils, one must resort to materials like iron or steel, which possess magnetic properties. These materials are capable of generating and conducting magnetic fields, unlike aluminum.

Send your message to us

China Color Coated Aluminum Coil - Aluminium Profile Glass Wall Usage with Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords