Sapa Aluminum Profiles for Door and Window Making

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Profile for Door and Windows Making Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profile for Door and Windows Making:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

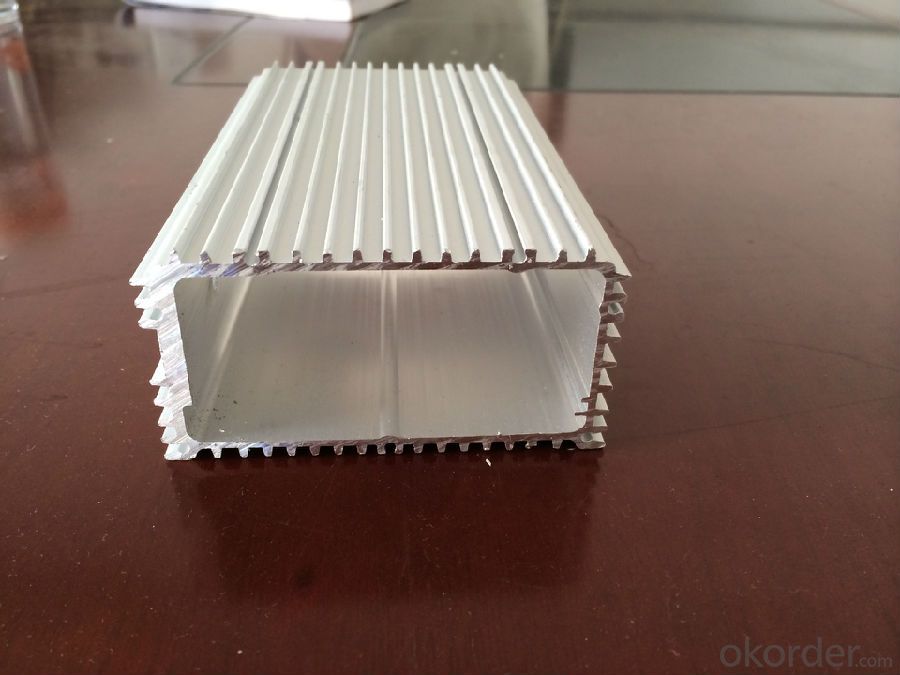

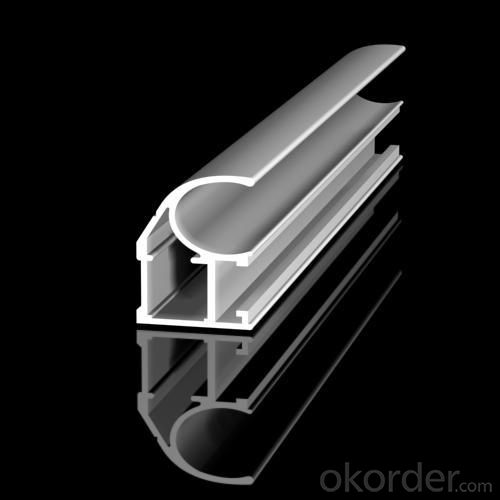

3.Aluminium Profile for Door and Windows Making Images:

4.Aluminium Profile for Door and Windows Making Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Are aluminum profiles suitable for constructing railings or staircases?

- <p>Yes, aluminum profiles are commonly used for railings and staircases due to their strength, durability, and low maintenance requirements. They offer a modern aesthetic and are resistant to corrosion, making them ideal for both indoor and outdoor applications. Aluminum profiles can be easily customized to fit various designs and can be powder-coated or anodized for enhanced visual appeal and protection against the elements.</p>

- Q: Can aluminum profiles be used for industrial workbenches?

- Indeed, industrial workbenches can make use of aluminum profiles. Thanks to its lightweight and durable properties, aluminum proves to be an excellent choice for different industrial purposes as it resists corrosion effectively. One advantage of aluminum profiles is their easy customization, which allows for the creation of workbenches with precise dimensions and configurations. Moreover, aluminum profiles come in a wide array of sizes and shapes, offering design flexibility. As a result, utilizing aluminum profiles in the construction of industrial workbenches can provide not only strength and versatility but also long-lasting performance.

- Q: Can aluminum profiles be used in marine environments?

- Yes, aluminum profiles can be used in marine environments. Aluminum is often chosen for its excellent corrosion resistance and lightweight properties, making it ideal for marine applications. It is commonly used in the construction of boats, shipbuilding, and offshore structures due to its durability and ability to withstand exposure to saltwater and harsh weather conditions.

- Q: Explain the advantages of utilizing aluminum profiles in the construction industry.

- <p>Aluminum profiles offer several benefits in construction, including high strength-to-weight ratio, which means they are strong yet lightweight. This reduces the load on structures and facilitates easier handling and installation. They are also corrosion-resistant, ensuring longevity and low maintenance costs. Aluminum profiles are recyclable and environmentally friendly, contributing to sustainable construction practices. Their malleability allows for versatile design and customization, accommodating various architectural needs. Additionally, they have excellent thermal conductivity, which can be beneficial for heat management in buildings. Lastly, their aesthetic appeal and modern look enhance the visual appeal of construction projects.</p>

- Q: This question asks for methods to prevent rust formation on aluminum profiles during the periods of storage and transportation.

- <p>To prevent rust on aluminum profiles during storage and transportation, follow these guidelines: 1. Keep aluminum profiles dry and clean, avoiding contact with moisture or corrosive substances. 2. Store profiles in a cool, dry place, away from direct sunlight and heat sources. 3. Use protective packaging materials to shield profiles from physical damage and moisture. 4. Apply a protective coating or sealant to the aluminum surface if it's exposed to harsh environments. 5. Regularly inspect stored profiles for signs of corrosion and address any issues promptly. By adhering to these practices, you can minimize the risk of rust formation on aluminum profiles during storage and transportation.</p>

- Q: Is it possible to recycle aluminum profiles and incorporate them into new construction projects?

- <p>Yes, aluminum profiles can be recycled and reused in new building projects. Aluminum is highly recyclable, and the recycling process is energy-efficient, requiring only 5% of the energy needed to produce new aluminum. Recycled aluminum maintains its properties, making it suitable for various applications in construction. This practice not only conserves resources but also reduces waste and environmental impact.</p>

- Q: What are the color options available for aluminum profiles?

- There is a wide range of color choices for aluminum profiles, allowing for customization to meet individual preferences and design requirements. Common color options include silver, white, black, bronze, and different shades of grey. Moreover, it is possible to create custom colors by using powder coating or anodizing techniques on the aluminum profiles. These methods offer a vast array of colors, including vibrant tones and metallic finishes. Ultimately, there are numerous color possibilities for aluminum profiles, ensuring that individuals can find the ideal match for their particular project or aesthetic needs.

- Q: Are aluminum profiles suitable for outdoor use and can they withstand weathering?

- <p>Yes, aluminum profiles can be used for outdoor applications. They are resistant to corrosion and weathering due to their inherent properties and can be anodized or powder coated for additional protection against the elements. This makes them suitable for a variety of outdoor uses such as construction, furniture, and signage. However, it's important to ensure that the profiles are properly finished and maintained to prolong their lifespan and performance outdoors.</p>

- Q: The subject is aluminum bearing in what u ~ on both sides of the track?? How can the track be fitted into this slot? Both sides secure 50Mechanical expert answers!The subject is aluminum bearing in what u ~ on both sides of the track?? How can the track be fitted into this slot? How can the seat of fixed motor on both sides be connected with the section bar?

- The bearings are mounted on type U rails, which are specially made on the market. The rails and profiles are integral, not mounted.

- Q: Can aluminum profiles be used for creating lightweight furniture?

- Yes, aluminum profiles can be used for creating lightweight furniture. Aluminum is a lightweight and durable material, making it ideal for constructing furniture that is easy to move and transport. Additionally, aluminum profiles can be easily customized and shaped to create various furniture designs while maintaining their lightweight properties.

Send your message to us

Sapa Aluminum Profiles for Door and Window Making

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords